High-efficiency nitrogen and phosphorus synchronous removal method in treating low concentration wastewater

A simultaneous denitrification and dephosphorization, low-concentration technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effects of shortening HRT, increasing treatment load, and increasing treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

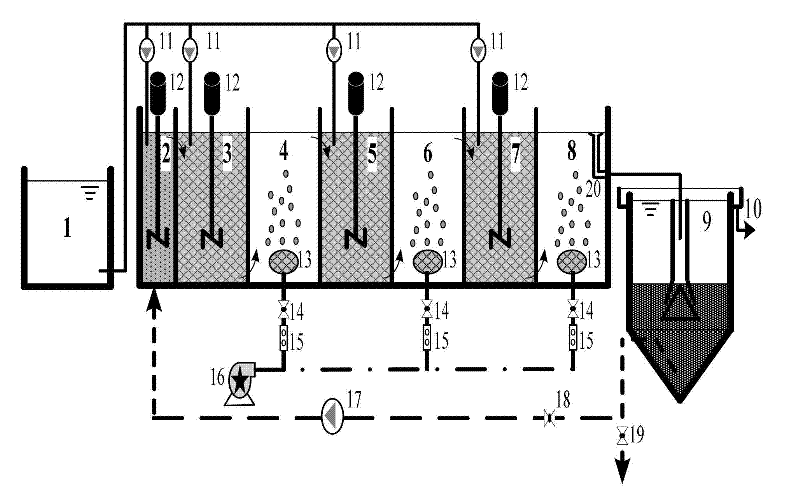

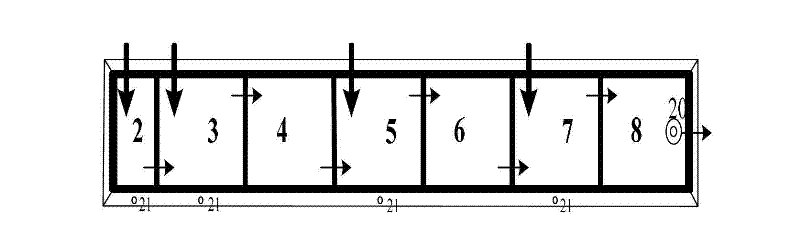

Method used

Image

Examples

example

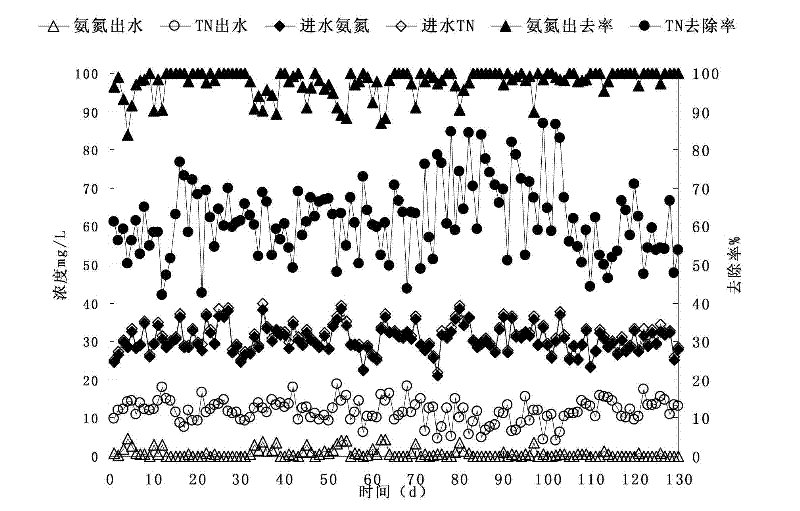

[0047]Taking the effluent of the swirling grit chamber of a sewage treatment plant in Jiangsu Province as the treatment object (COD=89-200mg / L, TN=22-42mg / L, TP=2.2-6.7 mg / L, C / N=2.18- 6.2, C / P=21.2-78.8), hydraulic retention time 8.7h, sludge age 10-15d, average sludge concentration 5600 mg / L, sludge reflux ratio 50%-75%, temperature controlled by heating rod at 20 -22°C, the anaerobic / anoxic / aerobic volume ratio is 4:8:10. The test results show that the optimal flow distribution ratio of the system is 20%:35%:35%:10%; under this working condition, the effluent quality of COD, ammonia nitrogen, total nitrogen, and total phosphorus are 33.05 mg.L respectively -1 , 0.58 mg.L -1 , 9.26 mg.L -1 , 0.46 mg.L -1 , and the removal rates were 78.90%, 98.31%, 70.24%, and 86.11%, respectively.

[0048] image 3 In order to take the actual sewage as the treatment object, the system has been continuously operated for more than 4 months to remove ammonia nitrogen and TN. In the case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com