Ageing-resistant tire belt rubber composition

A technology of rubber composition and belt layer, which is applied in the field of rubber, can solve the problems of inconspicuous effect and little effect, and achieve the purpose of improving the adhesion between steel wire and rubber, increasing the service life, and improving the aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

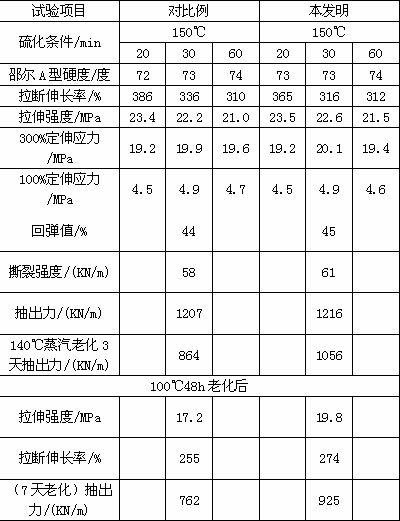

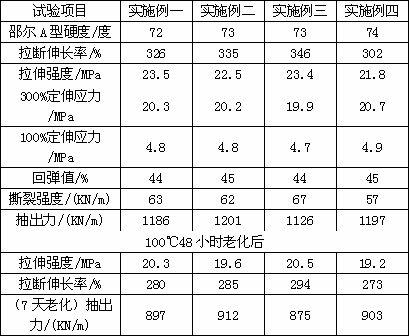

Examples

Embodiment Construction

[0009] Below in conjunction with embodiment the present invention will be further described:

[0010] The present invention is made of the following raw materials in parts by weight: natural rubber 100, carbon black 40-50, white carbon black 5-15, zinc oxide 6-10, anti-aging agent 4020 1.0-2.5, adhesive B-20- S 1.0-3.0, binder HMT 1.0-3.0, cobalt caprate 0.5-1.5, zinc borate 1.0-4.0, insoluble sulfur 4.0-7.0, vulcanization accelerator 1.0-2.0, anti-scorch agent CTP 0.2.

[0011] As a preference, the dosage of the zinc borate is preferably 1-4 parts.

[0012] Preferably, the vulcanization accelerator is shared by vulcanization accelerator DZ and vulcanization accelerator NS, DZ is 0.5-1 part, and NS is 0.5-1 part.

[0013] Insoluble sulfur is preferably HDOT20.

[0014] Adopt raw material component and content described in the present invention to be able to prepare by existing routine technology, concrete steps are:

[0015] The first stage of mixing: add natural rubber, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com