Method for comprehensively extracting valuable metals from tellurium-containing polymetallic materials

A technology for comprehensive extraction of valuable metals, which is applied in the field of hydrometallurgical process and comprehensive extraction of valuable metals, can solve the problems of difficult-to-handle grades, low tellurium-containing materials, and high production costs, and achieve reduced production costs and high tellurium recovery rates , The effect of saving technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

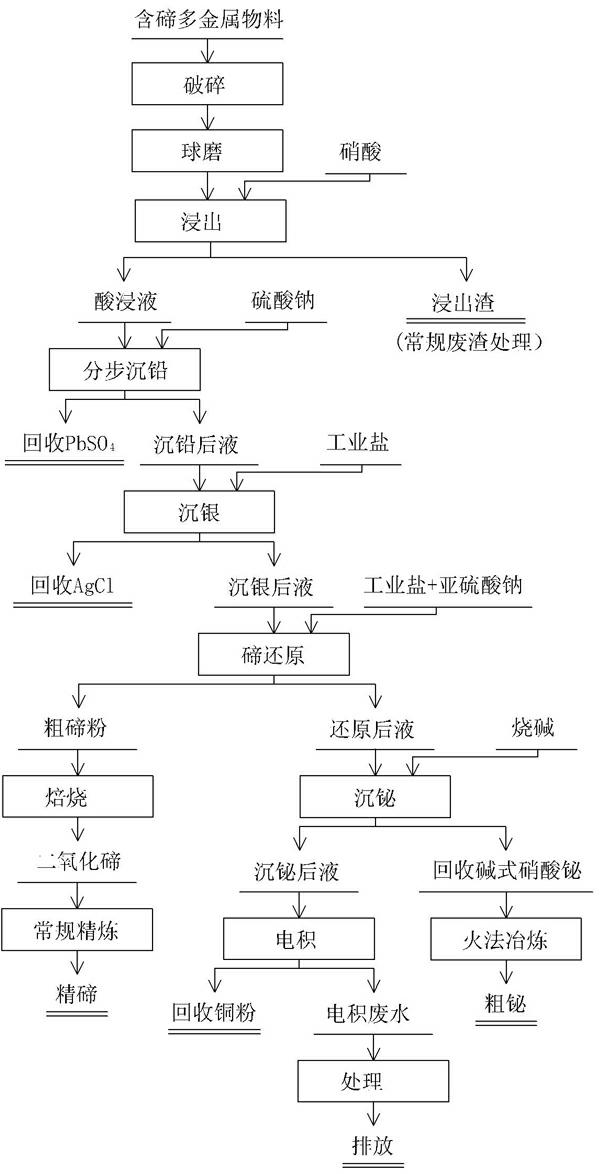

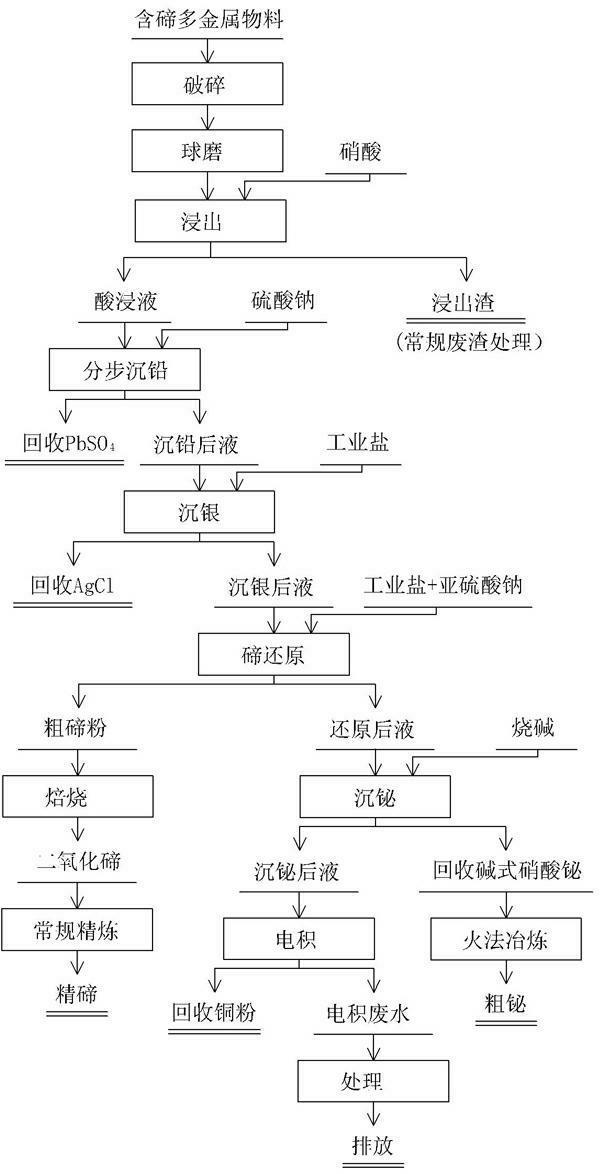

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The composition of the tellurium-containing smelting slag used in this embodiment is as follows:

[0027] Pb22.27%, Cu12.06%, Te5.74%, Bi27.1%, Ag3.2024%;

[0028] The technological steps of extracting refined tellurium from the above-mentioned tellurium-containing smelting slag and comprehensively recovering valuable metals are shown in the appendix figure 1 .

[0029] The specific process and process parameters are as follows:

[0030] a. Oxidation leaching

[0031] Large pieces of tellurium-containing polymetallic materials are crushed by a crusher to a particle size of less than 3cm; then ground by a wet ball mill, and the particle size is required to be below 150 mesh; nitric acid is used as an oxidant and leaching agent to leach lead, copper, bismuth, silver, and tellurium. Let all the valuable metals enter the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com