Recovery system with heat accumulator for internal combustion engine exhausting waste heat and control method

A technology of exhaust waste heat and recovery system, which is applied in the direction of internal combustion piston engine, coolant flow control, exhaust device, etc., and can solve the problem that the dynamic working process lasts for a long time, cannot realize practical application, cannot make full use of internal combustion engine, etc. problem, to achieve the effect of small output power fluctuation, high useful work output, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

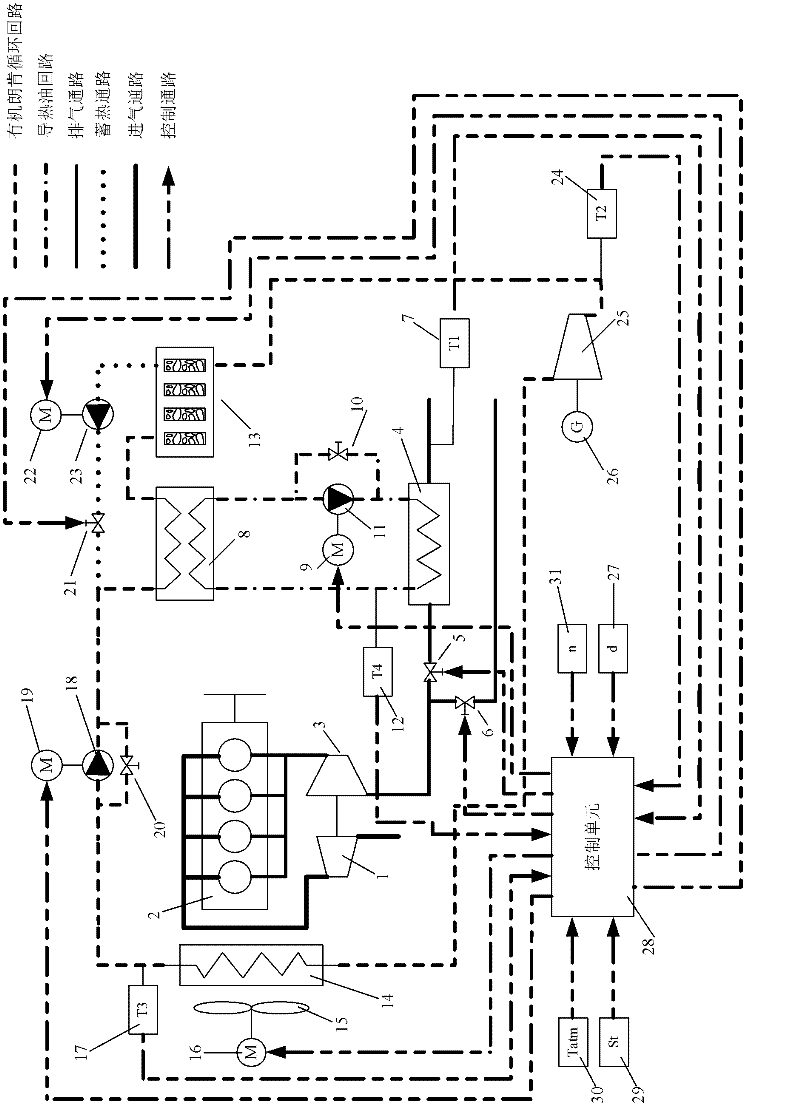

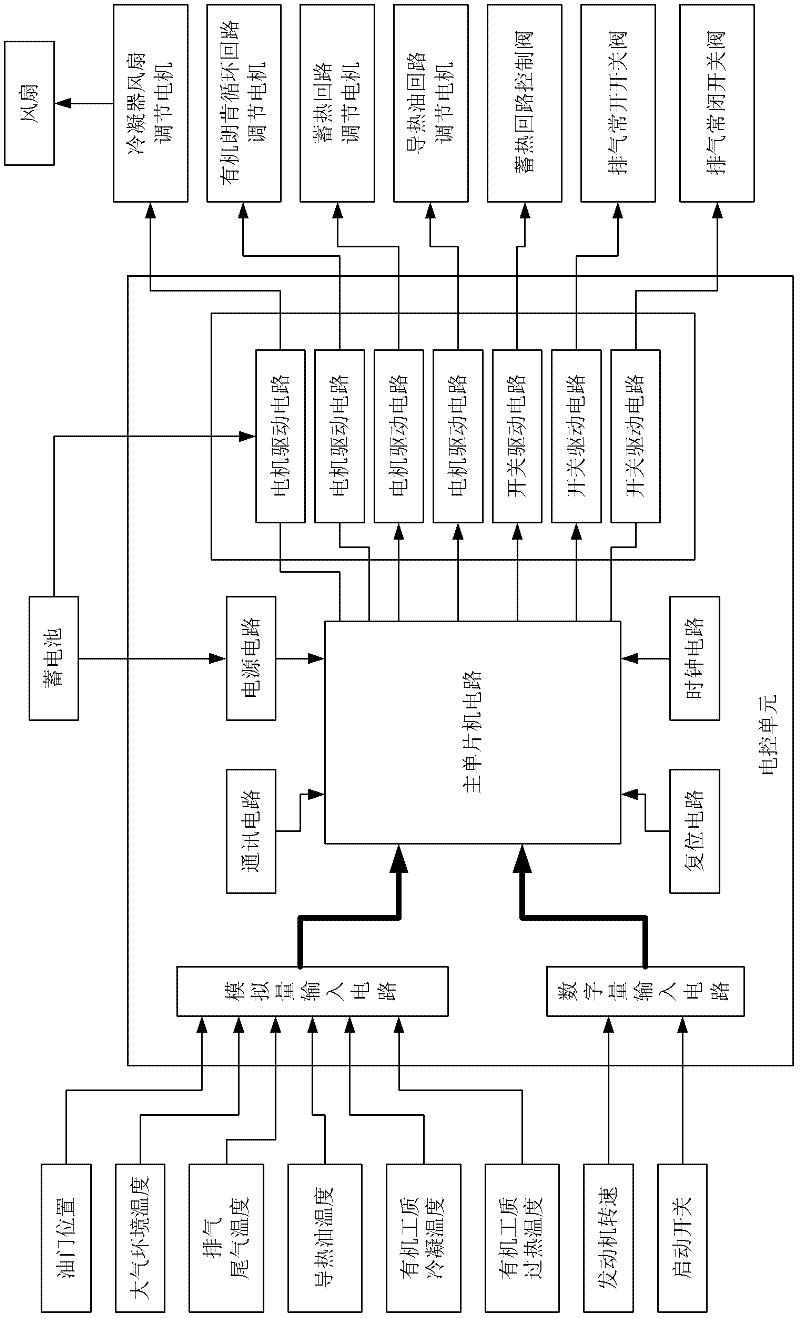

[0034] The exhaust waste heat recovery system of internal combustion engine with heat accumulator of the present invention, its connection diagram is as follows figure 1 As shown, including heat transfer oil circuit, organic Rankine cycle circuit, heat storage circuit and control circuit. The heat transfer oil circuit for absorbing exhaust heat of internal combustion engine includes the following components: working medium pump 11, regulating motor 9, pressure regulating valve 10, exhaust heat exchanger 4, evaporator 8, exhaust normally open switch valve 5, Exhaust normally closed on-off valve 6 and the pipeline connecting them. The components included in the organic Rankine cycle circuit for waste heat heat work conversion of internal combustion engines include: working fluid pump 18, regulating motor 19, pressure regulating valve 20, evaporator 8, heat acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com