Method for preparing thermoelectric material with P-type nano-structure and bismuth telluride matrix

A technology of thermoelectric materials and nanostructures, applied in the manufacture/processing of thermoelectric devices, etc., to achieve the effect of increasing phonon scattering, fine structure, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (Preparation of hot-pressed sintered samples with a hot-pressing temperature of 400°C, a pressure of 100 MPa, and a holding time of 2 hours)

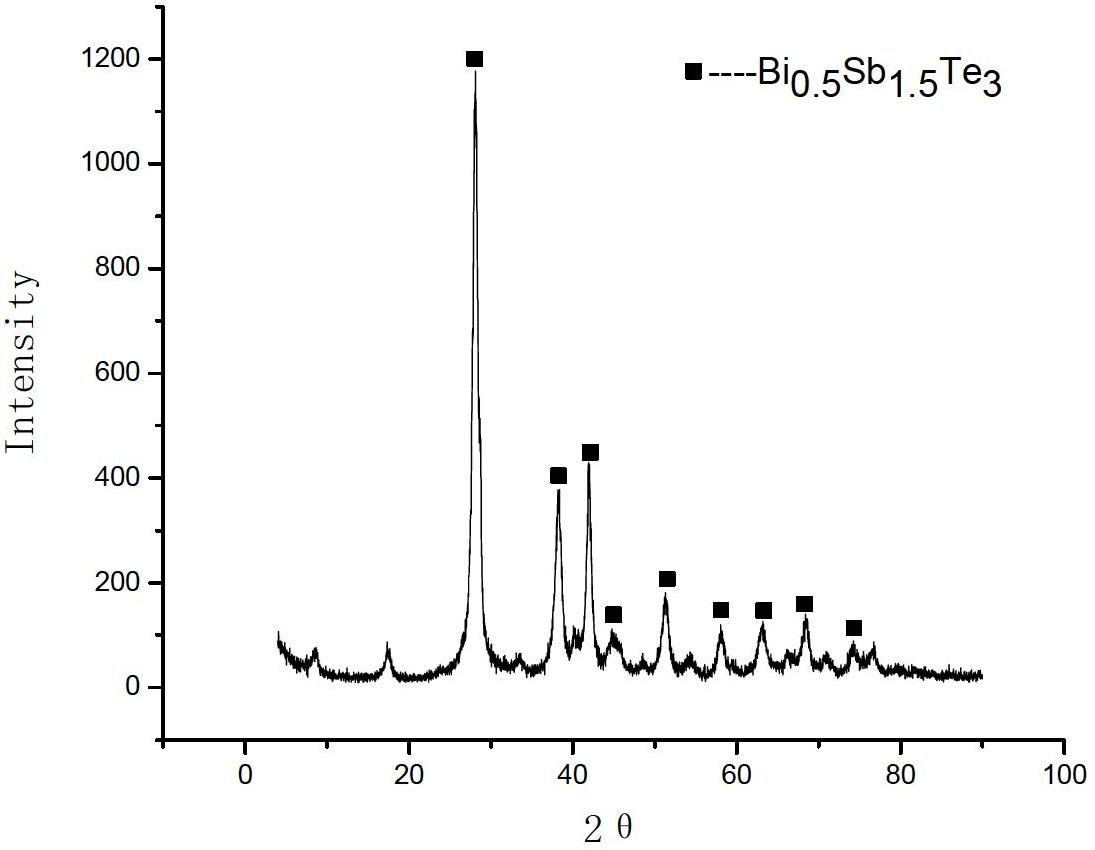

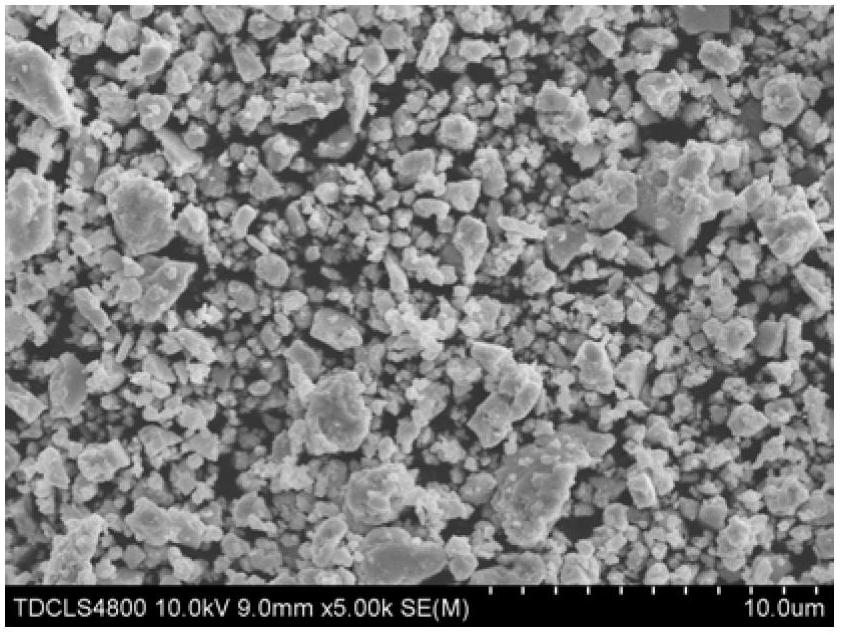

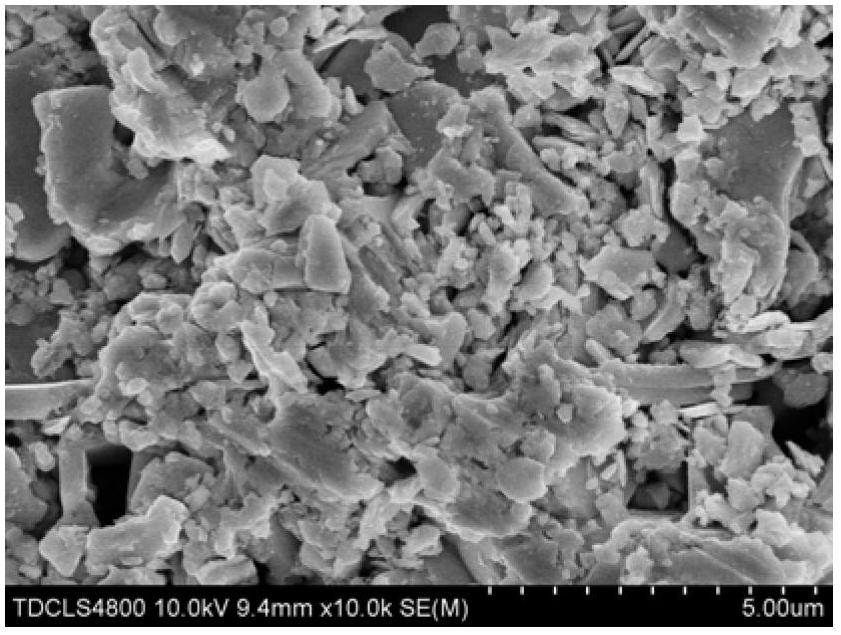

[0036] (1) The high-purity Bi, Sb, Te elemental powders are batched according to the atomic ratio of Bi: Sb: Te=0.5: 1.5: 3, the mixed powder is packed into a ball mill jar, and the purity of 99.7% alcohol is added as a ball mill medium, and the batching , canning and sampling were all carried out in a vacuum glove box. Ball milling is completed on a high-energy ball mill, using stainless steel ball milling tanks and balls. In order to prevent powder oxidation during the MA process, inert gas argon is introduced for protection. The ratio of balls to materials is 20:1, and the amount of alcohol added is such that the powder is not covered It is suitable to grind the balls, the ball milling speed is 450rpm, the ball milling time is 60h, and the fully alloyed Bi 0.5 Sb 1.5 Te 3 powder( figure 1 ), and its grain size can reach tens...

Embodiment 2

[0042] (Preparation of hot-pressed sintered samples with a hot-pressing temperature of 500°C, a pressure of 100 MPa, and a holding time of 2 hours)

[0043] (1) The high-purity Bi, Sb, Te elemental powders are batched according to the atomic ratio of Bi: Sb: Te=0.5: 1.5: 3, the mixed powder is packed into a ball mill jar, and the purity of 99.7% alcohol is added as a ball mill medium, and the batching , canning and sampling were all carried out in a vacuum glove box. Ball milling is completed on a high-energy ball mill, using stainless steel ball milling tanks and balls. In order to prevent powder oxidation during the MA process, inert gas argon is introduced for protection. The ratio of balls to materials is 20:1, and the amount of alcohol added is such that the powder is not covered It is suitable to grind the balls, the ball milling speed is 450rpm, the ball milling time is 60h, and the fully alloyed Bi 0.5 Sb 1.5 Te 3 powder( figure 1 ), and its grain size can reach te...

Embodiment 3

[0049] (Preparation of hot-pressed sintered samples with a hot-pressing temperature of 550°C, a pressure of 150 MPa, and a holding time of 2 hours)

[0050] (1) The high-purity Bi, Sb, Te elemental powders are batched according to the atomic ratio of Bi: Sb: Te=0.5: 1.5: 3, the mixed powder is packed into a ball mill jar, and the purity of 99.7% alcohol is added as a ball mill medium, and the batching , canning and sampling were all carried out in a vacuum glove box. Ball milling is completed on a high-energy ball mill, using stainless steel ball milling tanks and balls. In order to prevent powder oxidation during the MA process, inert gas argon is introduced for protection. The ratio of balls to materials is 20:1, and the amount of alcohol added is such that the powder is not covered It is suitable to grind the balls, the ball milling speed is 450rpm, the ball milling time is 60h, and the fully alloyed Bi 0.5 Sb 1.5 Te 3 powder( figure 1 ), and its grain size can reach te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com