Lithium oxide-rich cathode material with nitrogen or carbon-doped surface and preparation method for cathode material

A lithium-rich cathode material and lithium-rich technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor rate discharge performance of materials, low electronic and ionic conductivity, and low first charge and discharge efficiency. Good rate performance, high specific capacity, and the effect of improving Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Lithium-rich cathode material Li 1.17 Ni 0.25 mn 0.58 o 2 Preparation: prepare NiCl separately according to the stoichiometric ratio 2 and MnCl 2 The mixed solution (150 ml, the total concentration of metal ions is 0.25 moles per liter), LiOH solution (170 milliliters, 0.5 moles per liter), NiCl 2 and MnCl 2 The mixed solution was added to the LiOH solution, centrifuged, washed, and dried to obtain a precipitate. Another 2.390 g of LiOH was weighed and mixed with the above dry precipitate, ground, roasted in air at 500°C for 2 hours, cooled, fully ground, roasted in air at 750°C for 20 hours, quenched and dried to obtain Li 1.17 Ni 0.25 mn 0.58 o 2 .

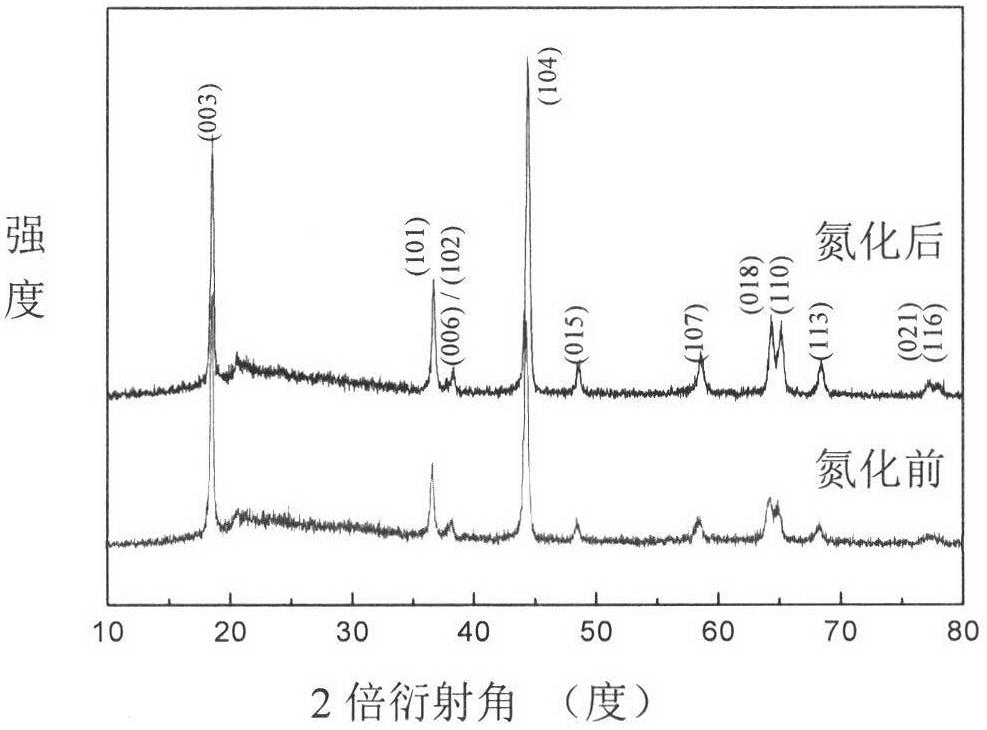

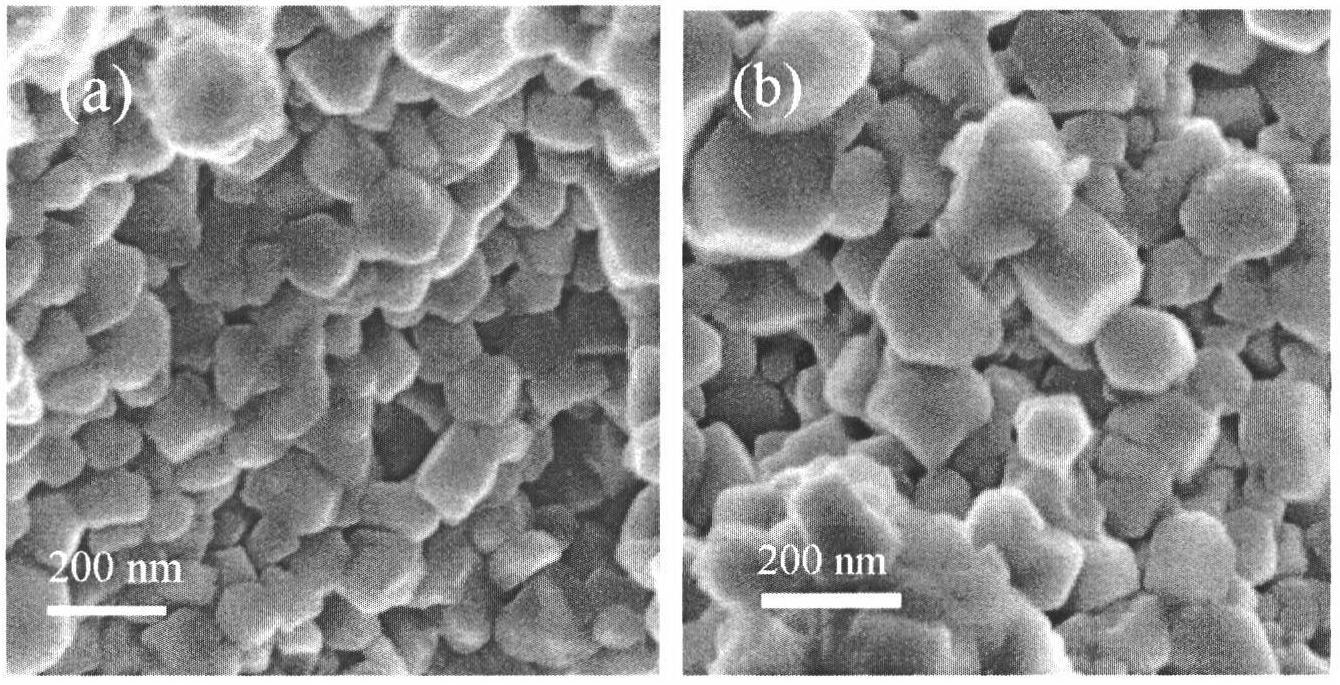

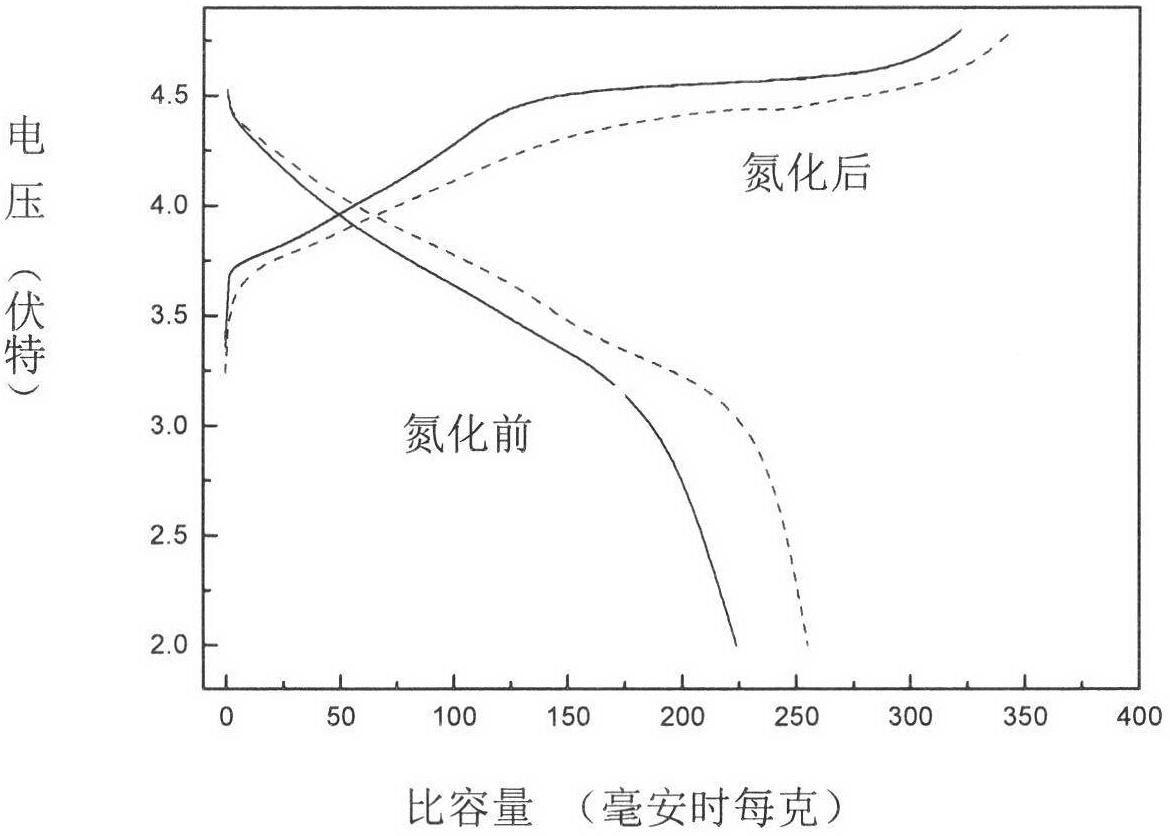

[0024] 2) Surface nitrogen-doped lithium-rich cathode material Li 1.17 Ni 0.25 mn 0.58 o 1.91 N 0.06 Preparation: the product Li prepared in step 1) 1.17 Ni 0.25 mn 0.58 o 2 placed in a tube furnace under flowing NH 3 Roasting at 400°C for 3 hours in air (gas flow rate 100 ml / min) and cooling down n...

Embodiment 2

[0029] 1) Lithium-rich cathode material Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 The total concentration of metal ions prepared respectively by the stoichiometric ratio is 0.5 moles per liter), and the amount of citric acid solution (1.46 moles per liter) is prepared according to the molar ratio of metal ions and citric acid substances in addition (1.46 moles per liter), under strong stirring conditions , the CH 3 COOLi, Ni(CH 3 COO) 2 , Co(CH 3 COO) 2 , Mn(CH 3 COO) 2 The mixed solution was dropped into the citric acid solution, and the solution was evaporated to dryness at 120° C. with stirring to form a gel. Roast in air at 500°C for 2 hours, cool and grind thoroughly, calcinate in air at 750°C for 20 hours, quench and dry.

[0030] 2) Surface carbon-doped lithium-rich cathode material Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 1.82 C 0.12 Preparation: the product Li prepared in step 1) 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 Placed in a tube furnace, flowing CH 4 and H 2 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com