Spreading oil insecticidal composition containing chlorpyrifos and buprofezin and application thereof

A technology of insecticidal composition and film-spreading oil, which is applied in the application, insecticide, biocide and other directions, can solve the problems such as the inability to meet the diversified needs of pest control, and achieve the advantages of saving man-hours, convenient use and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

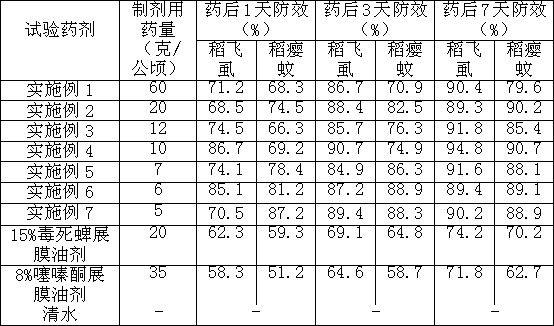

Examples

Embodiment 1

[0022] Embodiment 1: 5.5% chlorpyrifos · buprofezin film spreading oil

[0023] 1. Composition (weight percent):

[0024] Chlorpyrifos 5%, Buprofezin 0.5%, Alkylbenzenesulfonate Sodium Salt 10.5%, Glycerol 12%, Polyethylene Glycol Glycidyl Ether 18%, Isoamyl Alcohol 30%, Sodium Lauryl Sulfate twenty four%.

[0025] 2. Preparation method:

[0026] First mix the sodium salt of alkylbenzenesulfonate, chlorpyrifos and buprofezin according to the proportion, heat to 20-80°C, keep warm for 2 hours, then cool to room temperature, add glycerol, polyethylene glycol glycidyl ether, Isoamyl alcohol and sodium lauryl sulfate are added while stirring, fully mixed evenly, and finally left to stand for 5 hours to obtain the required 5.5% chlorpyrifos·buprofezin film-developing oil product.

Embodiment 2

[0027] Embodiment 2: 15% chlorpyrifos · buprofezin film spreading oil

[0028] 1. Composition (weight percent):

[0029] Chlorpyrifos 12%, Buprofezin 3%, Biphenol Polyoxyethylene Ether 15%, Polyethylene Glycol 8%, Cresyl Glycidyl Ether 15%, Isoamyl Alcohol 17%, Sodium Lauryl Sulfate 30%.

[0030] 2. Preparation method:

[0031] First mix biphenol polyoxyethylene ether, chlorpyrifos and buprofezin in proportion, heat to 20-80°C, keep warm for 5 hours, then cool to room temperature, add polyethylene glycol, cresyl glycidyl ether, isoamyl alcohol, Sodium lauryl sulfate, stir while adding, fully mix evenly, and finally let it stand for 8 hours to get the required 15% chlorpyrifos-buprofezin film-developing oil product.

Embodiment 3

[0032] Embodiment 3: 25% chlorpyrifos · buprofezin film spreading oil

[0033] 1. Composition (weight percent):

[0034] Chlorpyrifos 20%, Buprofezin 5%, Alkylbenzenesulfonate Sodium Salt 20%, Sorbitol 15%, Polyethylene Glycol Glycidyl Ether 5%, Isoamyl Alcohol 10%, Polyacrylamide 25%.

[0035] 2. Preparation method:

[0036] First mix the sodium salt of alkylbenzenesulfonate, chlorpyrifos and buprofezin in proportion, heat to 20-80°C, keep warm for 6 hours, then cool to room temperature, add sorbitol, polyethylene glycol glycidyl ether, iso Amyl alcohol, polyacrylamide, stir while adding, fully mix evenly, and finally let it stand for 9 hours, you can get the required 25% chlorpyrifos·buprofezin film-developing oil product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com