A kind of microemulsion that forms nanoemulsion in situ and preparation method thereof

A nano-emulsion and micro-emulsion technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of high cost, easy to contaminate preparations, and high energy consumption, and achieve easy transportation, good stability, and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Based on 100 parts by weight, 76 parts of white oil, 8.36 parts of Span80, 10.64 parts of Tween80, and 5 parts of water are taken, of which 19 parts of Span80 and Tween80 are taken, and the weight ratio of the two is 11:14. Then put them in the reactor and mix them uniformly, and stir at 500 rpm for 5 minutes at room temperature to form a microemulsion that forms a nanoemulsion in situ.

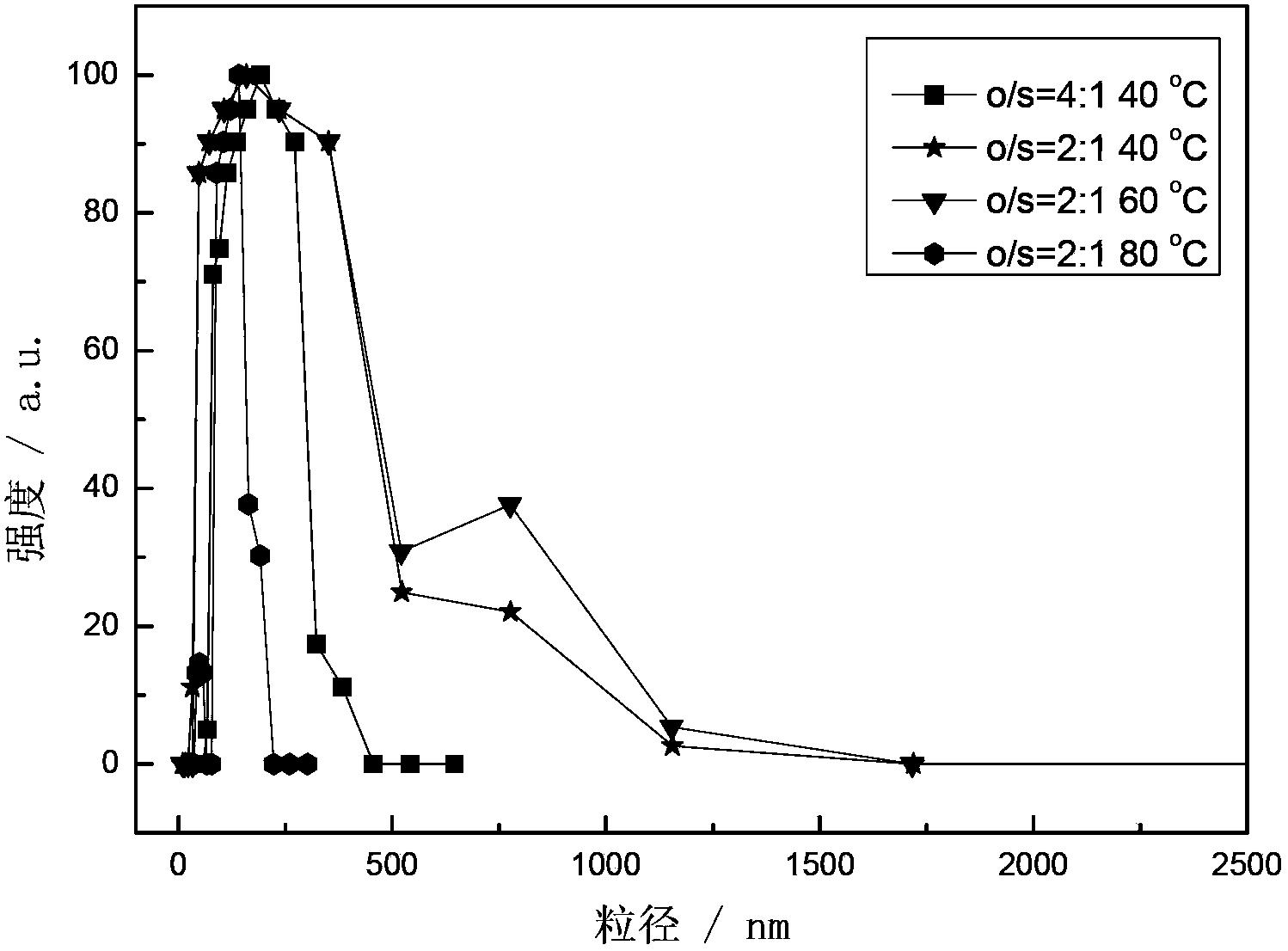

[0019] The high-temperature stability, long-term stability, and low-temperature stability of the prepared in-situ synthesized nanoemulsion were investigated according to the following methods, and the particle size distribution of the in-situ formed nanoemulsion after dilution:

[0020] 1. Stability measurement:

[0021] Long-term stability: The product is placed statically for a long time, observe the appearance, and pay attention to whether there is clear delamination.

[0022] High temperature stability: Place the sample in a 70°C incubator for 5 hours and observe the appearance to see if ...

Embodiment 2

[0031] Based on 100 parts by weight, take 45 parts of liquid paraffin, 19.8 parts of Span80, 25.2 parts of Tween80, 3.5 parts of NaCl, and 6.5 parts of water, of which Span80 and Tween80 are 45 parts, and the weight ratio between the two is 11:14 (0.7857). Dissolve 3.5 parts of NaCl in 6.5 parts of water to obtain the water phase; then mix 45 parts of liquid paraffin, 19.8 parts of Span80 and 25.2 parts of Tween80 with the prepared water phase in the reactor, and stir at 400 rpm at room temperature for 10 It can be made into a microemulsion that forms a nanoemulsion in situ within minutes.

[0032] The detection was carried out according to the method described in Example 1, and the results are as follows:

[0033] Appearance

Embodiment 3

[0035] Based on 100 parts by weight, take 72 parts of liquid paraffin, 7.92 parts of Span80, 10.08 parts of Tween80, 1 part of D230, 1 part of NaCl and 8 parts of water. Among them, there are 18 parts of Span80 and Tween80. The weight ratio of the two is 11:14 ( 0.7857). Dissolve 1 part of D230 and 1 part of NaCl in 8 parts of water to obtain the water phase; then mix 72 parts of liquid paraffin, 7.92 parts of Span80 and 10.08 parts of Tween80 with the prepared water phase in the reactor and mix it evenly at room temperature at 200 rpm Stirring at a rotation speed of 10 minutes per minute can be made into a microemulsion that forms a nanoemulsion in situ.

[0036] The detection was carried out according to the method described in Example 1, and the results are as follows:

[0037] Appearance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com