Material particle screening device for plastic extrusion granulation system

A technology of extrusion granulation and screening device, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of affecting product quality, oxidative discoloration of pellets, poor screening effect, etc., to avoid oxidative discoloration, accelerate The effect of dust flow and preventing clogging of sieve holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

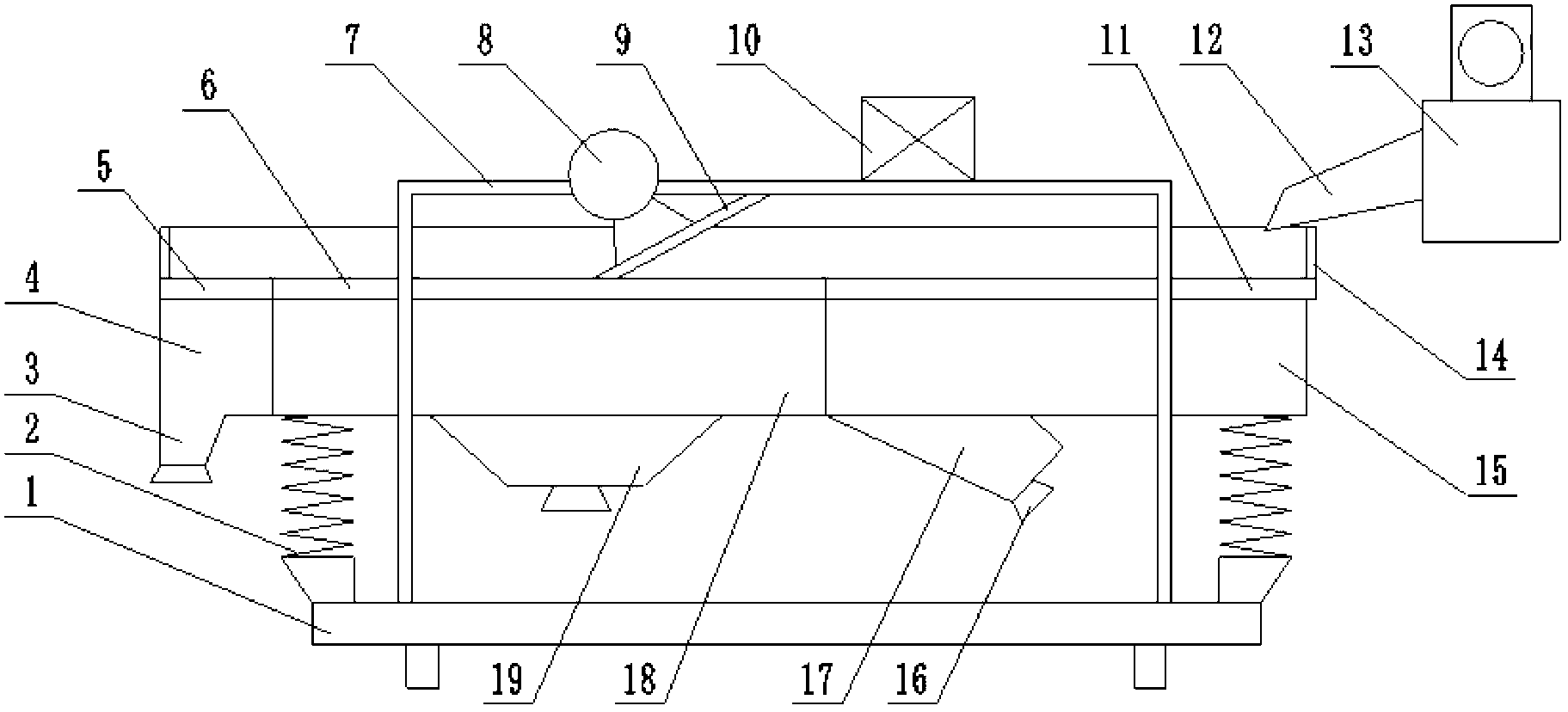

[0012] figure 1 Shown the overall mechanical configuration relation of the present invention, this device comprises frame 7, motor, screen cloth, feed bin and damping spring 2, and screen cloth is fixed on feed bin upper side, and vibrator 8 is installed on frame 7 and screen cloth. Between the nets, at least two damping springs 2 are installed at the bottom of the silo, and a blower 10 is installed on the upper frame 7 of the screen.

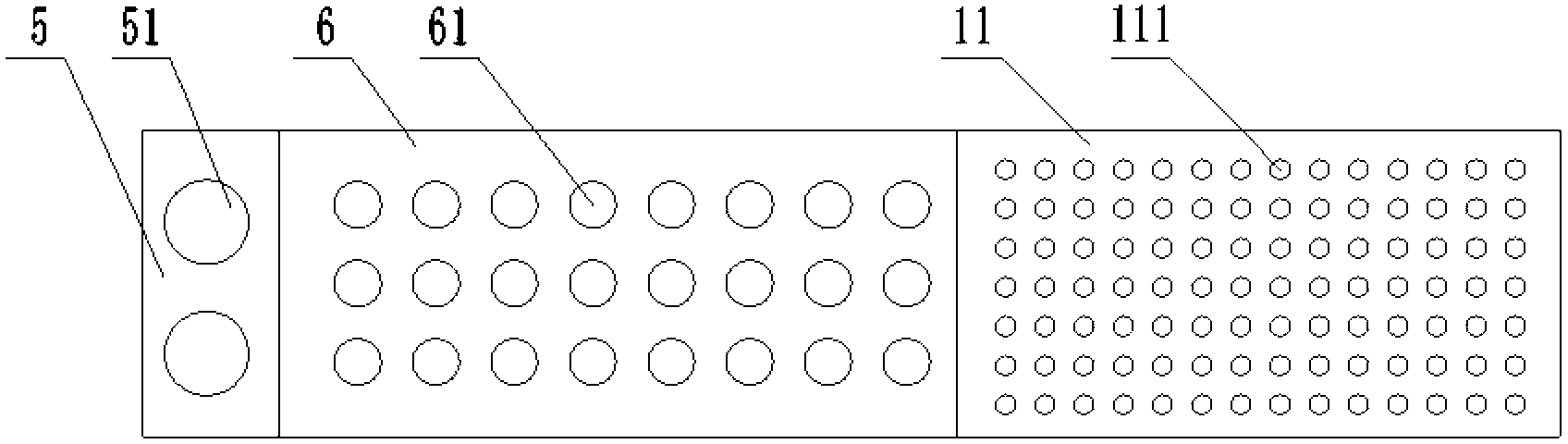

[0013] The screen is composed of dust sieve 11, qualified material sieve 6 and large material sieve 5 which are connected end to end to form an integral plane. The silos 4 are respectively provided with a dust outlet 17, a qualified material out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com