Preparation method of solid state chemistry micro-propeller

A solid-state chemical and thruster technology, applied in the direction of gaseous chemical plating, pattern surface photolithography, instruments, etc., can solve the problems of not being able to obtain a deep combustion chamber and the difficulty of metal processing, so as to avoid the corrosion rate. control, reduce process difficulty, and avoid safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

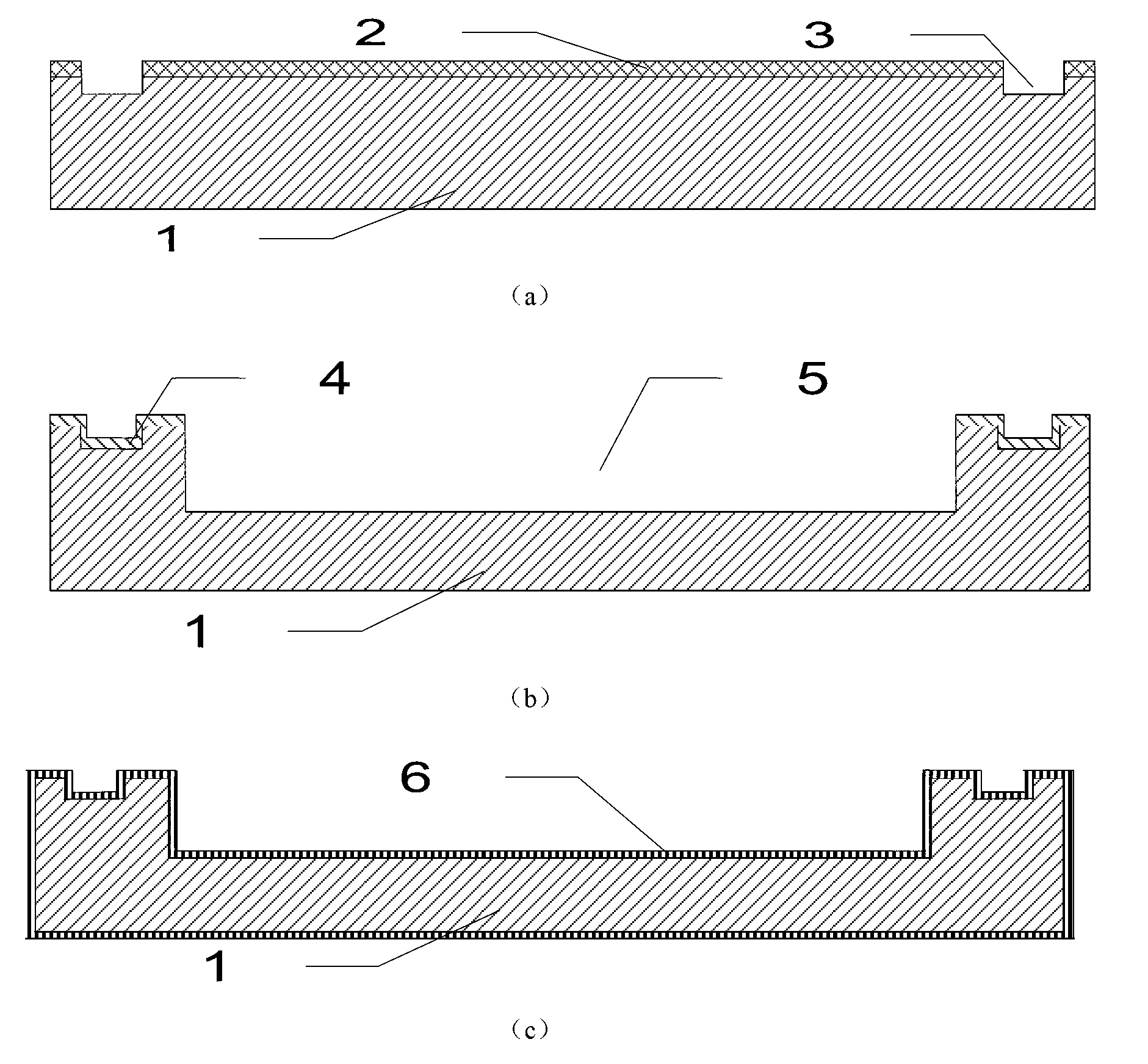

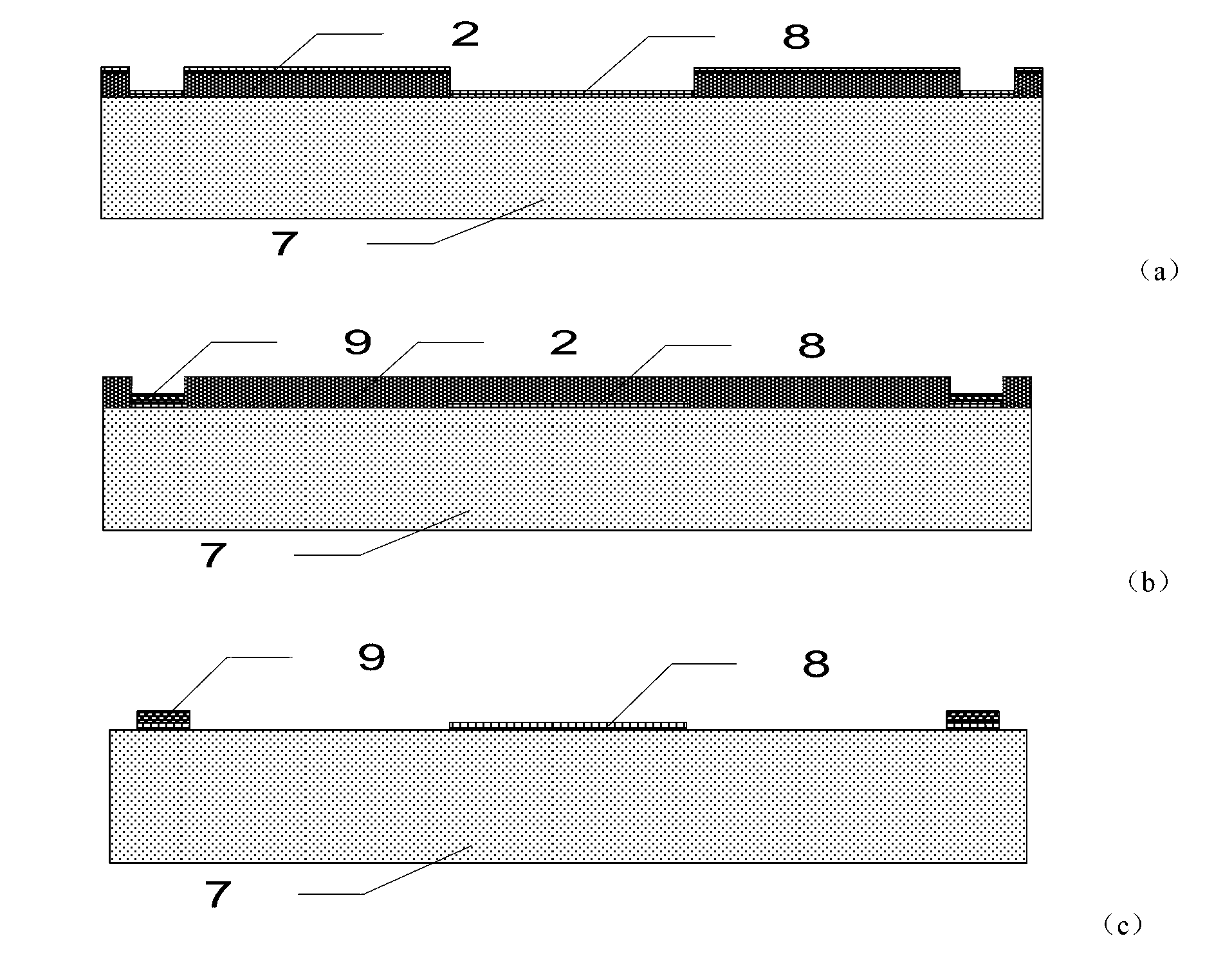

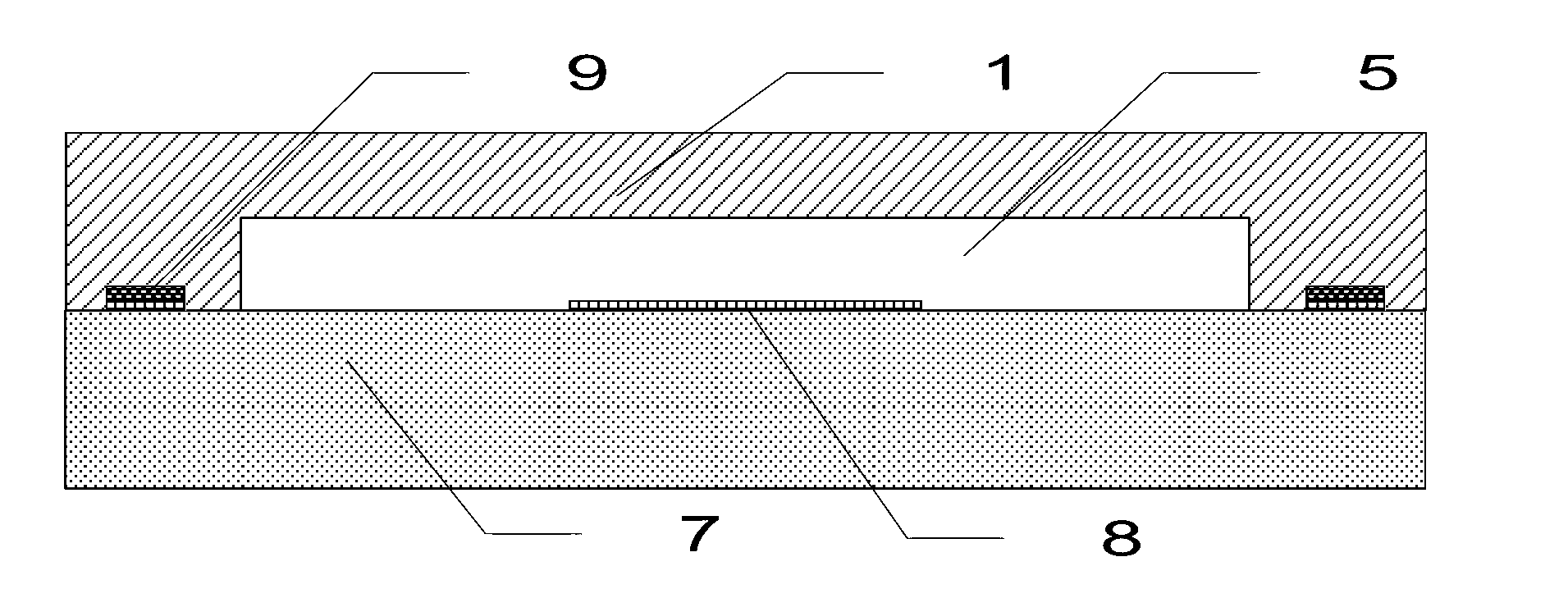

[0022] In this example, a kind of Figure 4 The preparation method of the shown miniature solid-state chemical propulsion device, this micro-solid-state chemical propulsion device comprises bonded silicon chip 1 and glass chip 7; The surface 14 of silicon chip 1 is recessed to form combustion chamber 5 and nozzle 15; Combustion chamber 5 both sides There are respectively linear lower wire grooves 16 and upper wire grooves 3; the glass sheet 7 is composed of heat-resistant glass 17 and an ignition circuit structure thereon, and the ignition circuit structure includes an igniter 18 at a position corresponding to the combustion chamber 5, and the igniter The two ends of 18 are respectively connected to the upper pad 12 and the lower pad 13 through the upper ignition wire 10 and the lower ignition wire 11; The material of the welding pad 13 is copper; in order to increase the ejection speed, the nozzle 15 has a convergent-divergent shape, and in this embodiment the throat at the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com