Titanium tetrachloride-poly dimethyl diallyl ammonium chloride inorganic-organic compound flocculant and preparation method thereof

A technology of polydimethyl diallyl ammonium chloride and dimethyl diallyl ammonium chloride, applied in the field of environment and chemistry, can solve the problems of narrow dosage range and high water treatment cost, and achieve the dosage range The effect of wide, low water treatment cost and good water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

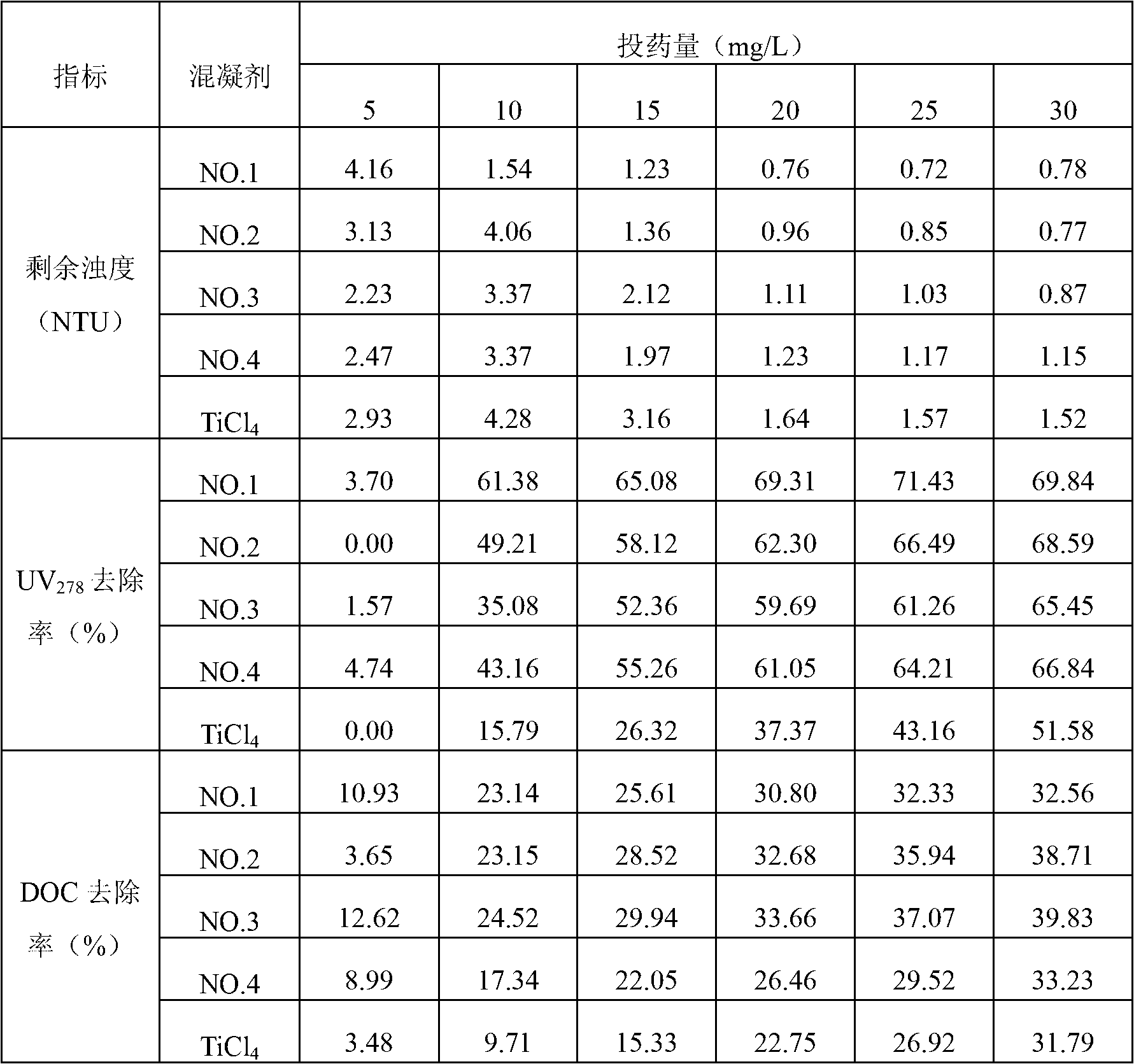

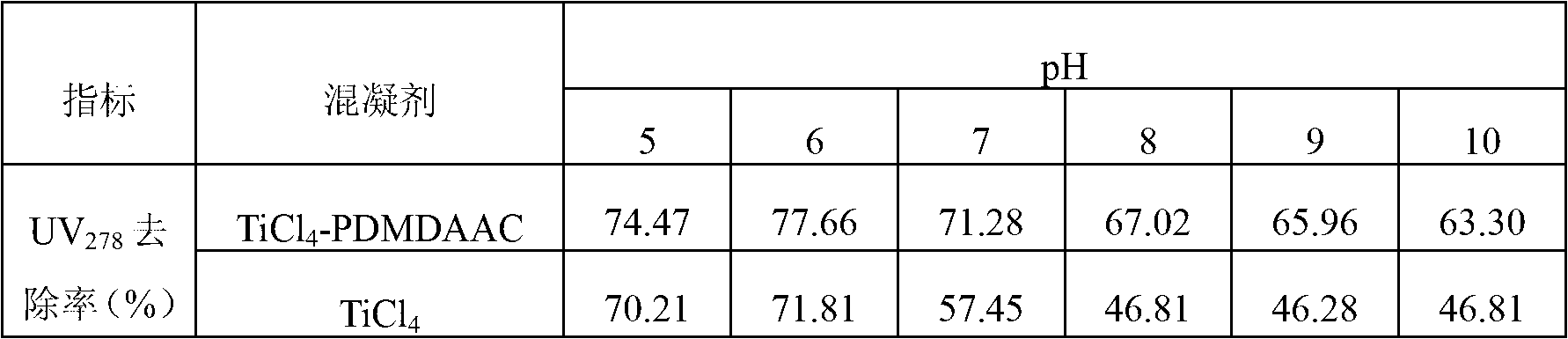

Embodiment 1

[0021] Weigh 1.2813g PDMDAAC (40.0% solid content) into a beaker, add 25.0ml of titanium tetrachloride solution, stir for 5.5h, and obtain TiCl with a mass ratio of Ti:PDMDAAC=4:1 4 -PDMDAAC inorganic-organic composite flocculant, the product prepared here is represented by No.1.

[0022] The TiCl 4 - The appearance of the PDMDAAC inorganic-organic composite flocculant is a light yellow liquid, containing 6.80% by weight of Ti and 4.25% by weight of PDMDAAC.

Embodiment 2

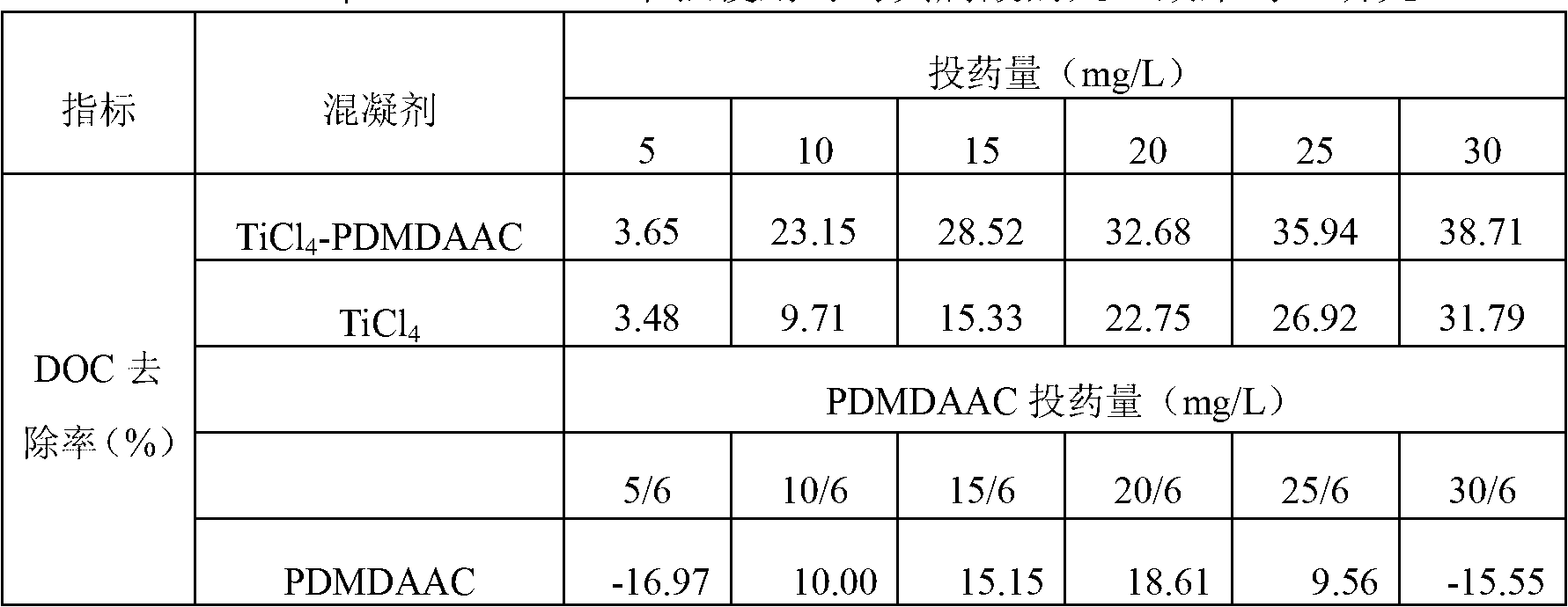

[0024] Weigh 0.8541g PDMDAAC (40.0% solid content) into a beaker, add 25.0ml of titanium tetrachloride solution, stir for 5 hours, and obtain TiCl with a mass ratio of Ti:PDMDAAC=6:1 4 -PDMDAAC inorganic-organic composite flocculant, the product prepared here is represented by No.2.

[0025] The TiCl 4 - The appearance of PDMDAAC inorganic-organic composite flocculant is light yellow liquid, containing 6.90% by weight of Ti and 2.87% by weight of PDMDAAC.

Embodiment 3

[0027] Weigh 0.6406g PDMDAAC (40.0% solid content) into a beaker, add 25.0ml of titanium tetrachloride solution, stir for 5 hours, and obtain TiCl with a mass ratio of Ti:PDMDAAC=8:1 4 -PDMDAAC inorganic-organic composite flocculant, the product prepared here is represented by No.3.

[0028] The TiCl 4 - The appearance of the PDMDAAC inorganic-organic composite flocculant is a colorless liquid, containing 6.95% by weight of Ti and 2.17% by weight of PDMDAAC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com