Alkali-added wet type oxidation catalytic desulfurization waste solution recycling method

A desulfurization waste liquid, wet oxidation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing the processing load of desulfurization equipment and reducing desulfurization efficiency, etc. Achieve the effect of small project area, high operation reliability and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

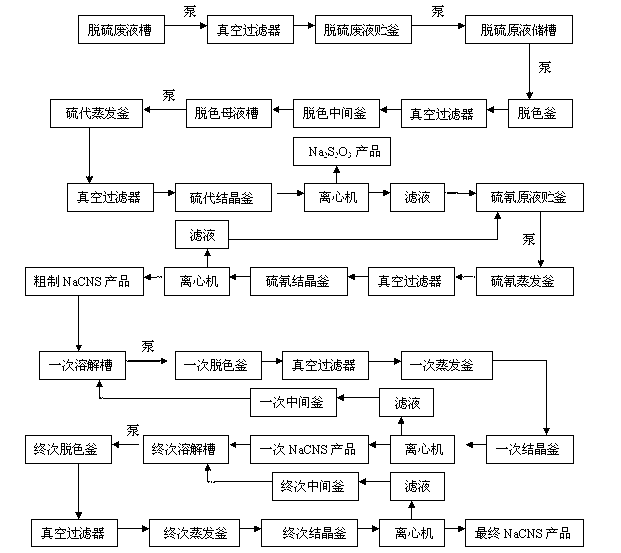

[0026] The desulfurization waste liquid is pumped to the vacuum filter to filter impurities, and then sucked into the desulfurization waste liquid storage tank and pumped into the desulfurization raw liquid storage tank. The desulfurization raw liquid storage tank plays the role of regulating and stabilizing the flow. The desulfurization stock solution is pumped into the decolorization kettle. Add industrial activated carbon into the decolorization kettle for decolorization, and the decolorization material liquid is filtered through a vacuum filter to remove activated carbon and impurities. After filtering, the feed liquid enters the decolorization storage tank, and then flows to the decolorization mother liquor tank by itself. Use a pump to press into the evaporator and steam to heat and concentrate. After the evaporation is complete, put the material liquid into the vacuum filter through the pipeline, and remove the Na by hot filtration. 2 CO 3 and other impurities. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com