Pure natural multi-element organic fertilizer and preparation method thereof

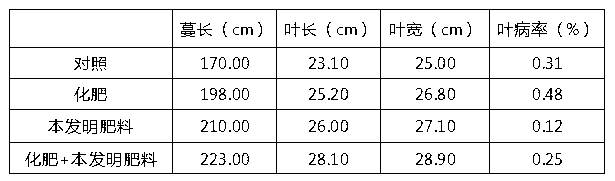

An organic fertilizer, a purely natural technology, applied in the preparation of organic fertilizers, organic fertilizers, bio-organic part treatment, etc., to achieve the effects of stable quality, increased single leaf area, and increased sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

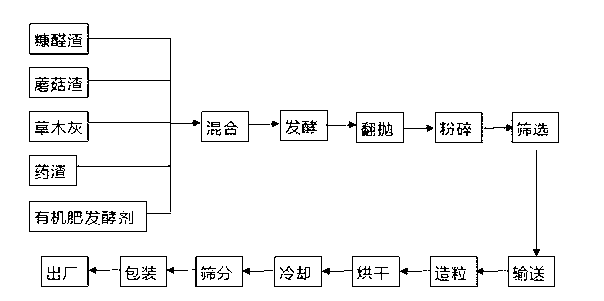

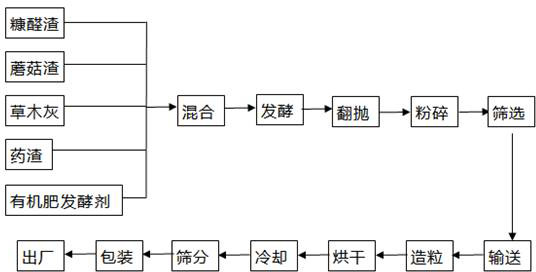

Method used

Image

Examples

Embodiment 1

[0031] Formula: 40 parts of furfural dregs, 40 parts of mushroom dregs, 15 parts of plant ash, 15 parts of medicinal dregs, 0.05 parts of organic fertilizer starter.

[0032] Specific manufacturing method: fully mix the raw materials obtained above, and control the moisture at about 45-50%, and control the pH value at 7.0-8.0, and then carry out stacking and fermentation. Generally, within 24 hours, the temperature will rise to 50 °C, within 48 hours, the temperature can rise to 60 °C-70 °C, when the temperature reaches 70 °C, turn over is required. Such temperature can kill all pathogenic bacteria and cordyceps seeds during fermentation; ferment for 7 days in spring, summer and autumn, and 10 days in winter to complete the fermentation, then pulverize through a pulverizer, sieve through a sieving machine, and then transport It is made into granules in a disc granulator, and then transported to a dryer and a cooler for drying and cooling, and then classified, screened ...

Embodiment 2

[0034] Formula: 50 parts of furfural dregs, 30 parts of mushroom dregs, 12.5 parts of plant ash, 20 parts of medicinal dregs, 0.05 parts of organic fertilizer starter.

[0035] Concrete manufacture method: except that proportioning is above-mentioned proportioning, all the other are with embodiment 1.

Embodiment 3

[0037] Formula: 60 parts of furfural dregs, 20 parts of mushroom dregs, 10 parts of plant ash, 10 parts of medicinal dregs, 0.05 parts of organic fertilizer starter.

[0038] Concrete manufacture method: except that proportioning is above-mentioned proportioning, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com