Novel polytetrafluoroethene (PTEF) nanocrystallization artificial blood vessel and preparation method thereof

A polytetrafluoroethylene, artificial blood vessel technology, applied in the fields of medical science, prosthesis, coating, etc., can solve the problems of unreported preparation methods, and achieve the purpose of reducing the degree of vascular intimal hyperplasia, improving the patency rate, and improving the curative effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 PTFE-MWNT

[0039] 1 experiment

[0040] 1.1 Raw materials and reagents

[0041] MWNTs (Shenzhen Nanometer Port Co., Ltd.) with a purity greater than 90% were used directly. PDDA solution (molecular weight: 200,000-350,000, Sigma-Aldrich, USA) was prepared into a 15 mg / ml ion solution. PTFE is taken from PTFE artificial blood vessel material imported from the United States, rubbed with sandpaper and treated with acetone and cut into 1cm 2 Use directly after size. Other chemicals and reagents were of analytical grade. The water used in the experiment was deionized water.

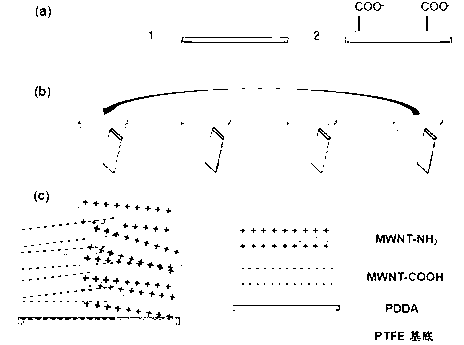

[0042] 1.2 Functionalization of MWCNTs

[0043] First, the MWNTs were dispersed in concentrated H 2 SO 4 / concentrated HNO 3 (3 / 1, v / v) in the mixed solution and stirred at 70°C for 4h. Then the obtained MWNT-COOH was repeatedly washed with water until neutral, and dried under vacuum at 70 °C for 12 h. Next, dry MWNT-COOH was added to SOCl at 70 °C 2 Stirr...

Embodiment 2

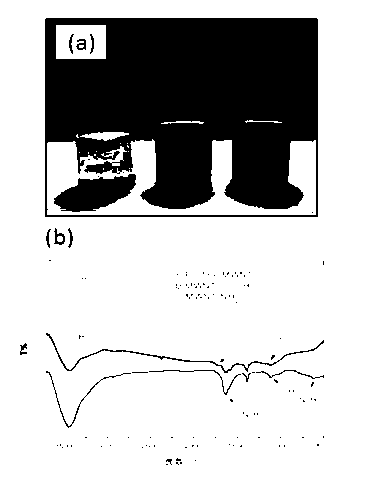

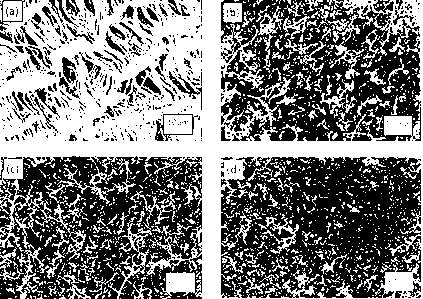

[0063] The animal experiment of embodiment 2 PTFE-MWNT

[0064] 1. Materials and methods

[0065] 1. Production of PTFE-MWNT

[0066] 1.1 Functionalization of multi-walled carbon nanotubes

[0067] MWNTs (Shenzhen Nanoport Co., Ltd.) dispersed in concentrated H 2 SO 4 / concentrated HNO 3 (3 / 1, v / v) in the mixed solution and stirred at 70°C for 4h. Then the obtained MWNT-COOH was repeatedly washed with water until neutral, and dried under vacuum at 70 °C for 12 h. Next, dry MWNT-COOH was added to SOCl at 70 °C 2 Stirred and refluxed for 24 hours, evaporated the remaining SOCl after the reaction was complete 2 , immediately adding the acyl chlorided MWNTs to NH 2 (CH 2 ) 2 NH 2 , stirred and refluxed at 70°C for 48h. Then the obtained MWNT-NH 2 Filter and wash several times, and vacuum-dry at 70°C for 24 hours for later use.

[0068] 1.2 Self-assembled MWNT films layer by layer on PTFE substrates

[0069] Combine dry MWNT-COOH with MWNT-NH 2 The powder was dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com