High light-transmittance and high light-shielding polystyrene composition and preparation method of composition

A polystyrene, high light-shielding technology, applied in the field of high light-transmitting, high light-shielding polystyrene composition and its preparation, can solve the problems of reducing the mechanical properties of luminescent materials, product quality, impact toughness, etc., and achieve production costs Effect of low, maintaining impact strength, and good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

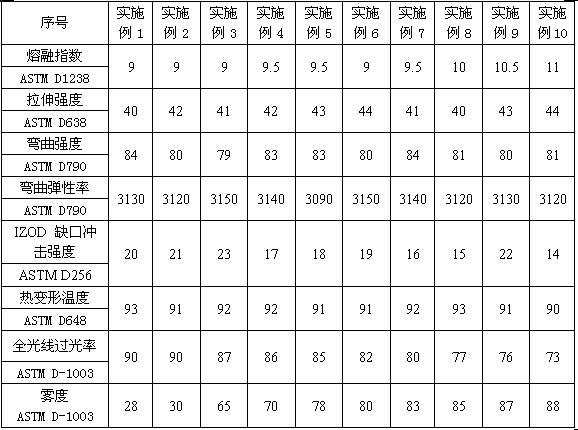

Examples

Embodiment 1

[0057] First, 0.1% of silicone resin light diffusing agent, 0.1% of vinyl bis stearamide, 0.1% of n-octadecyl alcohol of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate Put ester and 0.1% tris(2,4-di-tert-butylphenyl) phosphite into a high-speed mixer and stir evenly. The stirring speed of the high-speed mixer is 100r / min, and the stirring time is 5min; Styrene is stirred in three stages to make a uniform material. The stirring speed of the first stage is 20r / min, and the stirring time is 4min. The stirring speed of the second stage is 100r / min, and the stirring time is 4min. The stirring speed of the section stirring is 50r / min, and the stirring time is 4min; finally, the uniformly mixed material is put into a twin-screw extruder for extrusion and granulation. The exit temperature is 160°C, the extrusion temperature in the melt conveying section is 170°C, the head temperature is 170°C, and the vacuum degree during extrusion granulation is 0.6MPa.

Embodiment 2

[0059] First, add 0.2% silicone resin light diffusing agent, 0.1% vinyl bis stearamide, 0.1% n-octadecyl alcohol of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate Put ester and 0.1% tris(2,4-di-tert-butylphenyl) phosphite into a high-speed mixer and stir evenly. The stirring speed of the high-speed mixer is 110r / min, and the stirring time is 4min; Styrene is stirred in three stages to make a uniform material. The stirring speed of the first stage is 30r / min, and the stirring time is 3min. The stirring speed of the second stage is 120r / min, and the stirring time is 4min. The stirring speed of the section stirring is 20r / min, and the stirring time is 3min; finally, the uniformly mixed material is put into a twin-screw extruder for extrusion and granulation. The exit temperature is 170°C, the extrusion temperature in the melt conveying section is 180°C, the head temperature is 185°C, and the vacuum degree during extrusion granulation is 0.7MPa.

Embodiment 3

[0061] First, 0.3% of silicone resin light diffusing agent, 0.1% of vinyl bis stearamide, 0.1% of magnesium stearate, 0.1% of β-(3,5-di-tert-butyl-4-hydroxyphenyl ) n-octadecanyl propionate and 0.1% tris(2,4-di-tert-butylphenyl) phosphite were placed in a high-speed mixer and stirred evenly. The stirring speed of the high-speed mixer was 120r / min, and the stirring time was 4min; then add 99.3% polystyrene for three-stage stirring to make a uniform material. The stirring speed of the first stage of stirring is 35r / min, the stirring time is 3min, and the stirring speed of the second stage of stirring is 120r / min , the stirring time is 3min, the stirring speed of the third stage stirring is 30r / min, and the stirring time is 2min; finally, the uniformly mixed material is put into a twin-screw extruder for extrusion granulation, and the extrusion temperature of the pellet feeding section is 170°C, the extrusion temperature of the plasticizing section is 180°C, the extrusion tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com