A kind of plastic heat dissipation masterbatch and preparation method thereof

A technology of astigmatism and masterbatch, which is applied in the field of light diffusing materials, can solve the problem that the plastic astigmatism mask cannot dissipate heat, and achieve the effect of improving the heat conduction and heat dissipation effect and the luminous effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

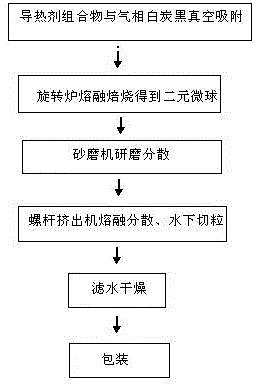

[0039] 1) Prepare 25% of the heat-conducting composition into a slurry with deionized water and add it to a vacuum reactor. The ratio of tin dioxide, zinc oxide, and boric acid in the heat-conducting composition is 10:3:1, and then add 50% of fumed white Carbon black, under the conditions of temperature 70-80 ℃ and vacuum degree of -0.2MPa, high-speed mixing, stirring and adsorption for 0.5 hours, and then discharging and drying;

[0040] 2) Melt and roast the adsorbent obtained in step 1) in a rotary calciner at a temperature of 800-950°C for 3 minutes to obtain a binary microsphere with high thermal conductivity and astigmatism;

[0041] 3) Put the binary microspheres obtained in step 2), 5% dispersant, and 2% lubricating aid into the disperser mixer, and disperse at a high speed for 10 minutes at 80-100°C, then add 20% matrix resin, and continue Stir for 3min, discharge;

[0042] 4) Send the mixture obtained in step 3) into a screw extruder, melt and disperse through the s...

Embodiment 2

[0045] 1) Prepare 30% of the heat-conducting composition into a slurry with deionized water and add it to a vacuum reactor. The ratio of tin dioxide, zinc oxide, and boric acid in the heat-conducting composition is 15:2:0.5, and then add 45% of fumed white carbon black , at a temperature of 70-80°C and a vacuum of -0.2MPa, high-speed mixing, stirring and adsorption for 1 hour, and then discharging and drying;

[0046] 2) The adsorbent obtained in step 1) was melted and roasted in a rotary calciner at a temperature of 800-950°C for 5 minutes to obtain a binary microsphere with high thermal conductivity and astigmatism;

[0047] 3) Add the binary microspheres obtained in step 2), 5% dispersant, and 1% lubricating aid to the disperser mixer, and disperse at a high speed for 15 minutes at 80-100°C, then add 17% matrix resin, 1 % antioxidant, anti-aging agent, continue to stir for 5min, discharge;

[0048] 4) Send the mixture obtained in step 3) into a screw extruder, melt and dis...

Embodiment 3

[0051] 1) Prepare 35% of the heat-conducting composition into a slurry with deionized water and add it to a vacuum reactor. The ratio of tin dioxide, zinc oxide, and boric acid in the heat-conducting composition is 12:2.5:0.5, and then add 40% of fumed silica , at a temperature of 70-80°C and a vacuum of -0.2MPa, high-speed mixing, stirring and adsorption for 0.5 hours, and then discharging and drying;

[0052] 2) Melt and roast the adsorbent obtained in step 1) in a rotary calciner at a temperature of 800-950°C for 3 minutes to obtain a binary microsphere with high thermal conductivity and astigmatism;

[0053] 3) Put the binary microspheres obtained in step 2), 5% dispersant, and 3% lubricating aid into the disperser mixer, disperse at a high speed for 10-20min at 80-100°C, and then add 16.5% K resin SL-803, 0.5% antioxidant and anti-aging agent, continue to stir for 5 minutes, and discharge;

[0054] 4) Send the mixture obtained in step 3) into a screw extruder, melt and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com