Environmental-friendly thermal insulation waterproof nanometer water-based coating

A water-based coating and nano-technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem that heat insulation materials are difficult to meet the requirements of use, and achieve excellent decoration and construction , weight insulation, colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

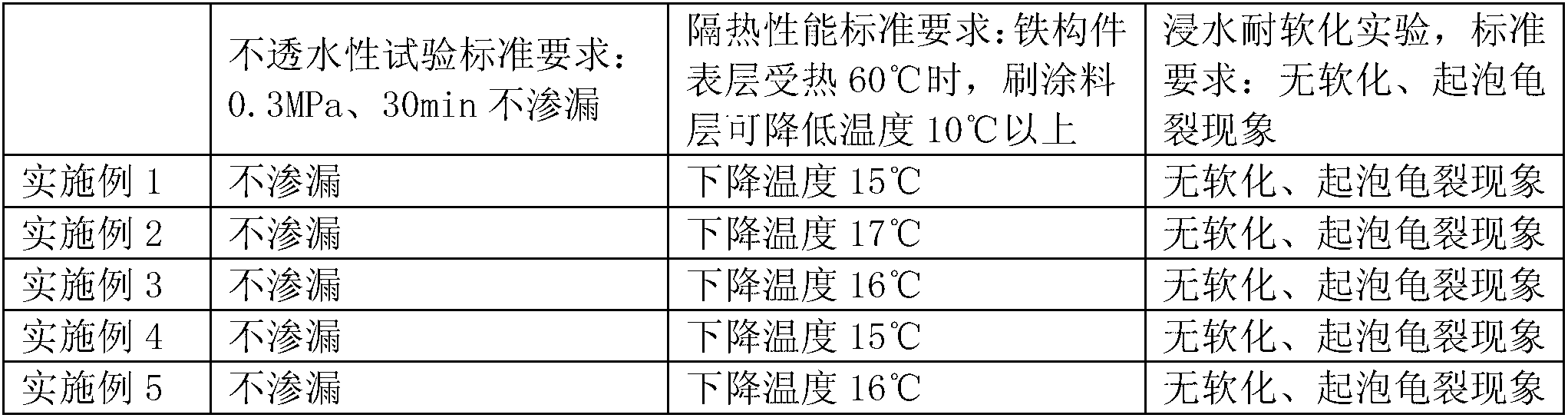

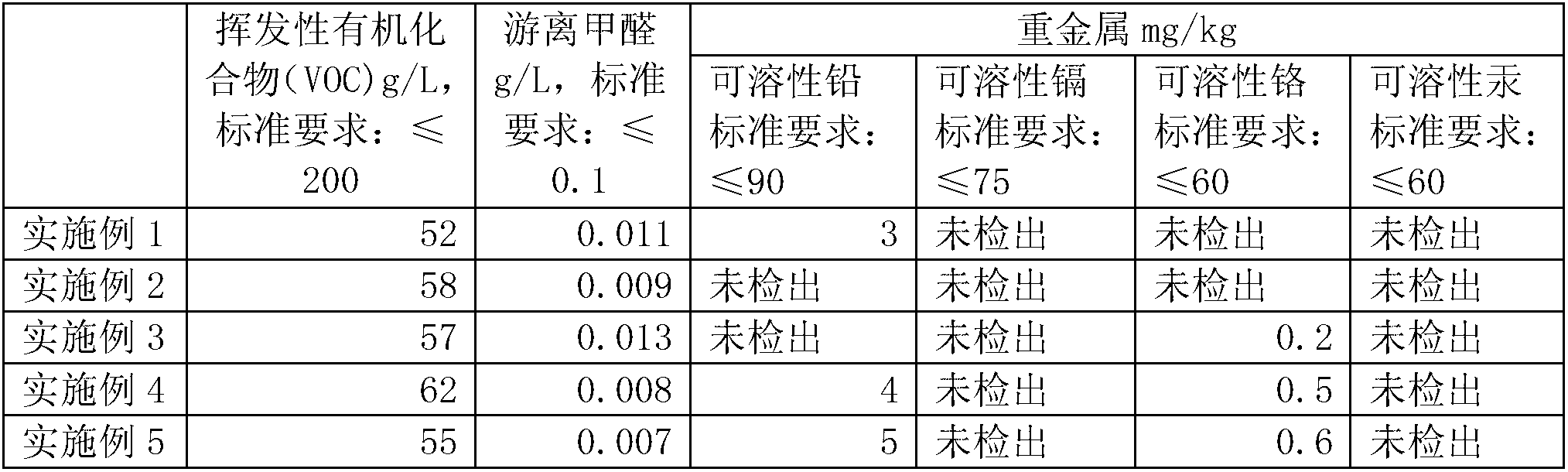

Examples

Embodiment 1

[0033] Ethylene-vinyl acetate copolymer EVA and acrylic acid copolymer emulsion 20 parts, diatomaceous earth 10 parts, nano-SiO 2 30 parts, 0.1 part of pH regulator, and 50 parts of water.

Embodiment 2

[0035] Ethylene-vinyl acetate copolymer EVA and acrylic acid copolymer emulsion 50 parts, diatomaceous earth 30 parts, nano-SiO 2 10 parts, 1 part of pH regulator, 20 parts of water, 3 parts of pigment, 0.5 part of defoamer, 1.0 part of thickener.

Embodiment 3

[0037] Ethylene-vinyl acetate copolymer EVA and acrylic acid copolymer emulsion 30 parts, diatomaceous earth 15 parts, nano-SiO 2 15 parts, 0.5 parts of pH adjuster, 10 parts of water, 5 parts of pigment, 1.0 part of defoamer, 0.3 part of dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com