Biomass particle gasification generator for kiln

A technology of biomass particles and generators, applied in the manufacture of combustible gas, petroleum industry, etc., can solve problems such as difficulty in meeting kiln production needs, uneven gas output and output, unstable combustion conditions, etc., to avoid gas leakage, The effect of uniform air outlet and uniform air outlet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

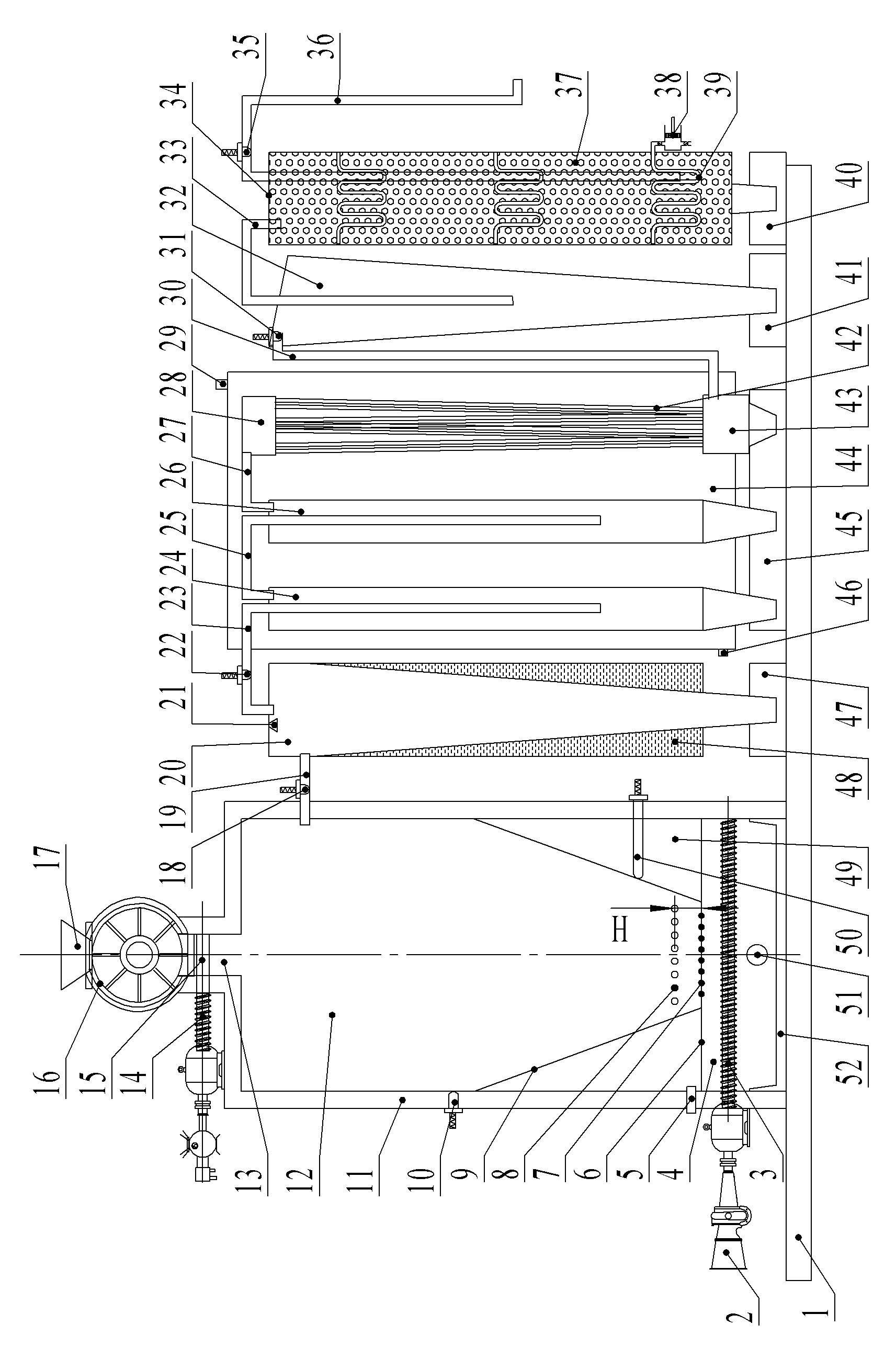

[0014] The furnace shell 11 of the furnace body is made of heat insulating material, and the furnace shell 11 is fixedly installed on the base 1. The furnace shell 11 is provided with a partition 6 with a grate 7 in the middle, and the bottom of the partition 6 is the ash bin 4. The bottom of the ash bin 4 is provided with a slag outlet, and the slag outlet is placed in the water-sealed pool 52. The ash bin 4 is built with a screw rod 3, and the screw rod 3 is connected with the power machine outside the furnace. The power machine in the embodiment adopts an electric motor. The engine driven by the actuator 2; the wall of the ash bin 4 is provided with an ignition port 51 in the water-sealed range of the water-sealed pool 52 that communicates with the outside; there is an inverted cone-shaped cylinder 9 above the partition 6 Connected between the partition 6 and the furnace shell 11, the cylinder body 9, the partition 6, and the furnace shell 11 enclose an air inlet uniform pre...

Embodiment 2

[0021] The structure of this embodiment is the same as that of Embodiment 1, only the size of the furnace body is different. In this embodiment, the height of the furnace 12 is 8 meters, and the inner diameter of the upper part of the furnace 12 is 2 meters. The height of the cylinder 9 is 1 meter. The inner diameter is 1 meter, and a furnace air inlet 8 is provided on the cylinder 9 at a height H of 15 cm above the grate 7. The furnace air inlet 8 is 16 circular holes with a diameter of 2 cm evenly arranged on the cylinder 9 .

Embodiment 3

[0023] The structure of this embodiment is the same as that of Embodiment 1, and only the furnace body size is different. In this embodiment, the height of the furnace 12 is 12 meters, the inner diameter of the furnace 12 top is 3 meters, and the height of the cylinder 9 is 2 meters. The inner diameter is 2 meters, and a furnace air inlet 8 is provided on the cylinder 9 at a height H of 20 cm above the grate 7. The furnace air inlet 8 is 20 circular holes with a diameter of 3 cm evenly arranged on the cylinder 9 .

[0024] Before using the biomass particle gasification generator for the kiln, put the biomass particles into the hopper 17, the blast pipe 5 is connected with the supporting blower, the water outlet 46 of the water tank 44 is connected with a water tap, and the gas output pipe 36 is connected with kiln. During use, close the tap on the water outlet 46, add cooling water from the water inlet 29, make the cooling water soak outside the large pipes 24, 26 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com