New technology for extracting high-purity gold by adopting wet process

A new process and high-purity technology, which is applied in the field of wet extraction of high-purity gold, can solve the problems of low pass rate, many factors affecting product quality, and unstable quality, and achieve the effect of stable product quality and shortened recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

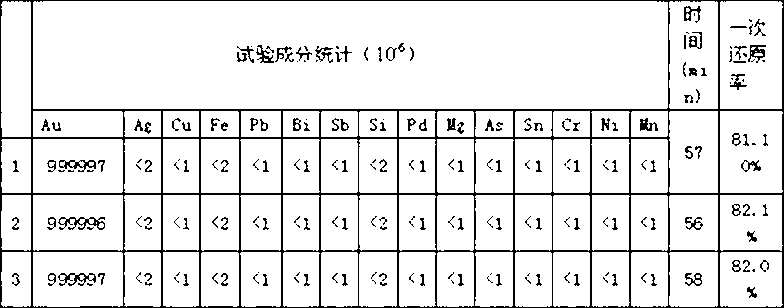

Embodiment 1

[0024] A. Weigh 1 kg of gold with a gold content of 99.99%, rinse it with water, take 40ml of nitric acid with a concentration of 65-68% and add 500ml of deionized water to make 5% dilute nitric acid, soak the gold for 10 minutes, and rinse it with deionized water until neutral;

[0025] B Put the gold into a glass reaction kettle, add 500ml of nitric acid (analytical pure) with a concentration of 65-68%, 1500ml of hydrochloric acid (analytical pure) with a concentration of 36-38%, and turn on the electric heating plate;

[0026] C. Dissolve gold for 2 hours, then add 800ml hydrochloric acid, heat and concentrate to 2000ml, and drive out NO3 in your solution - ;

[0027] D. Stop heating, add about 1330ml deionized water to dilute and cool to normal temperature, filter out the insoluble gold and AgCl precipitate in your solution;

[0028] E. Heat the filtrate to 30°C, and slowly pass SO into the filtrate 2 Gas, and constantly stir your liquid, control the temperature of your ...

Embodiment 2

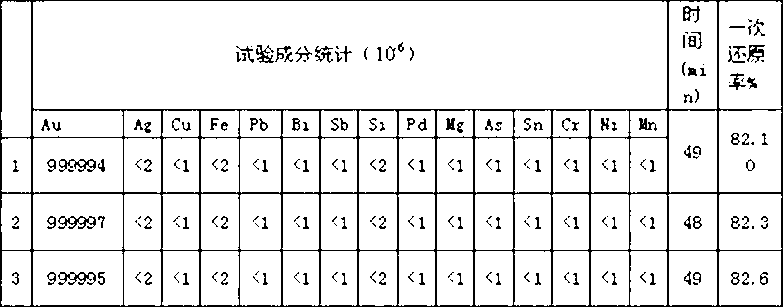

[0036] Weigh 1 kg of gold containing 99.992% gold, control the reduction temperature to 40° C., and the terminal potential to 700 mv according to the method of Example 1. Repeat the above implementation 3 times, the experimental results are as follows:

[0037]

Embodiment 3

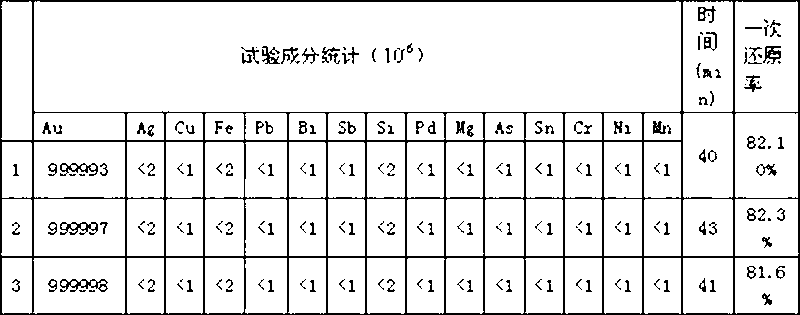

[0039] Weigh 1 kg of gold containing 99.992% gold, control the reduction temperature to 50° C., and the terminal potential to 700 mv according to the method of Example 1. Repeat the above implementation 3 times, the experimental results are as follows:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com