Coal Mining Method with Partial Isolation Grouting and Filling in Mined Overlying Rock

A technology of backfill mining and isolation grouting, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of large interference between backfill and coal mining, non-recovery, waste of resources, etc., and achieves low backfill and coal mining interference. The effect of reduced roadway excavation rate and increased working face width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

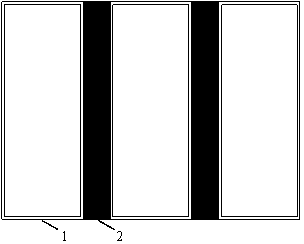

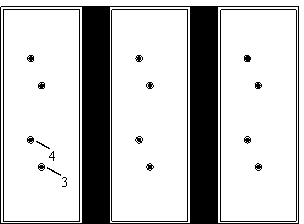

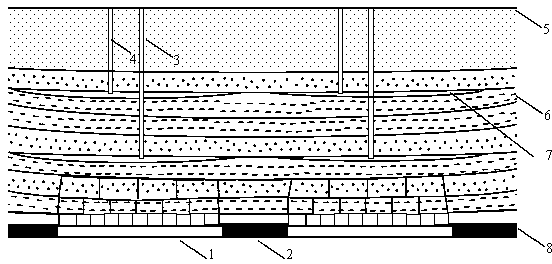

[0017] According to the geological conditions of the coal-pressing area of the building, the mining size parameters of the mining area are designed, and a reasonable width of the coal mining face is designed by setting a certain width The isolated coal pillars control the adjacent coal mining face to be in a non-full mining state, make full use of the self-bearing capacity of the overlying strata structure, and at the same time, during the mining process of the coal mining face, drill holes from the ground construction to the overlying strata Carry out grouting filling to form a grouting filling carrier, transfer and reduce the overlying rock load borne by the isolated coal pillar, limit the bending subsidence of the mining overlying rock structure, and slow down the surface subsidence. The specific method is: first divide the mining area into several coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com