Bipolar electromagnetic scanning micro lens

A scanning micromirror, bipolar technology, applied in television, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the long response time of devices , deal with complex circuits, limited application range and other issues, to achieve the effect of improving the work response time, low process complexity, and increasing the scanning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

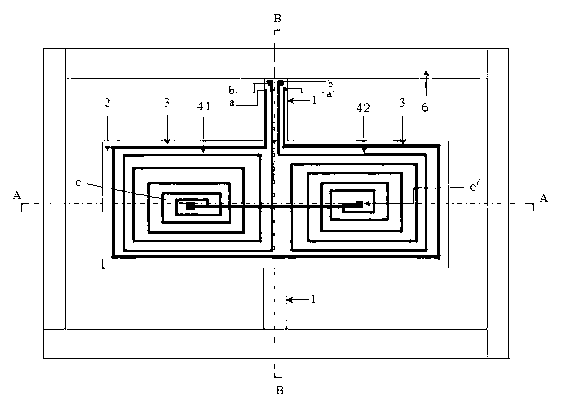

[0031] 1-torsion beam; 2-micro-mirror; 3-angle sensor; 41-micro-driver I; 42-micro-driver II; 6-support frame; a-angle sensor electrode I; a'-angle sensor electrode II; b- Drive electrode I; b'-drive motor II; c-connect electrode I; c'-connect electrode II.

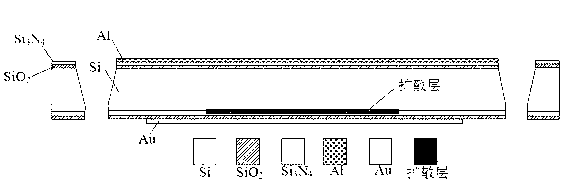

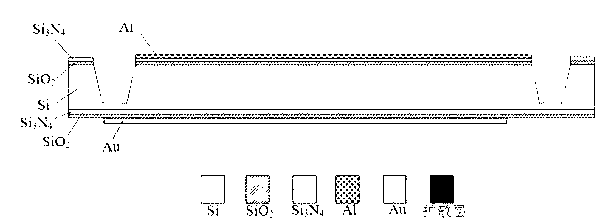

[0032] Such as Figure 1 to Figure 3 Shown, the bipolar electromagnetic scanning micromirror of the present invention comprises microreflection mirror surface 2, bipolar electromagnetic micro-drive coil and support frame 6, and reflection mirror surface 2, bipolar electromagnetic micro-drive coil and support frame 6 are all made in On the same silicon structure layer 5 and using the silicon structure layer 5 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com