Backpressure control system of large air-cooler unit

A technology for control systems and air-cooling units, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as poor control loop regulation performance, increased control loop interference, and decreased performance of steam turbine back pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

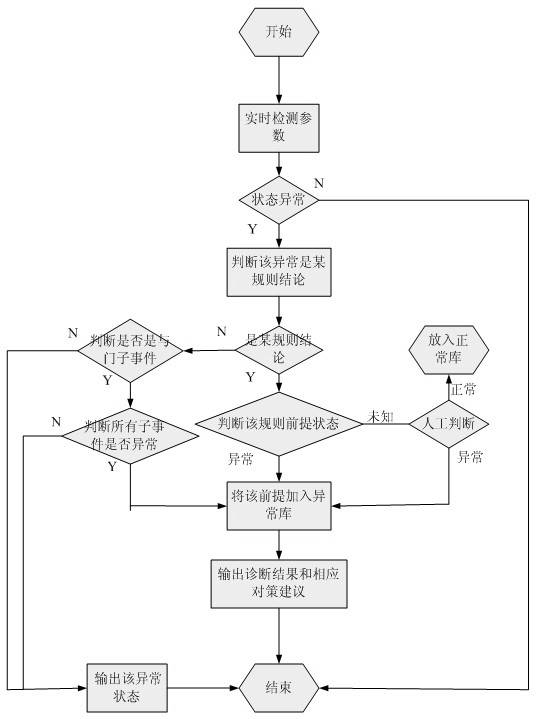

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiments.

[0011] The present invention adopts the following new ideas

[0012] (1) Increase the optimal economic back pressure automatic setting circuit

[0013] Considering the insufficient cooling capacity of the air-cooled island tube bundle in summer and the anti-freezing performance in winter, referring to the operating specifications of the steam turbine plant and according to the actual operation of the unit, the relationship function of ambient temperature, unit load and back pressure is designed. The back pressure control is changed from a simple control system with manual setting to an intelligent control system that automatically sets the best economical back pressure setting value.

[0014] (2) Increase the anti-interference circuit

[0015] In order to ensure the stability of the unit and the back pressure control, and to prevent the influence of the anti-freezing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com