Method for preparing monodisperse bismuth nano-particles

A bismuth nano- and monodisperse technology, applied in nanotechnology and other directions, can solve the problems of complicated steps, complicated bismuth sources, and complicated methods, and achieve the effects of simple steps, easy implementation and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

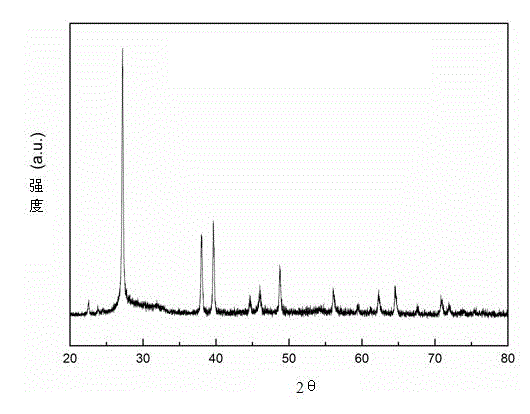

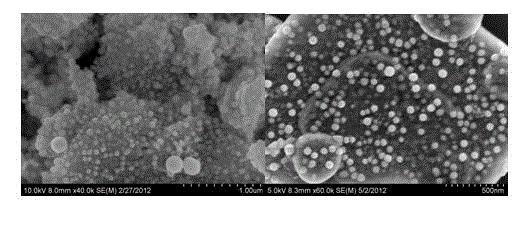

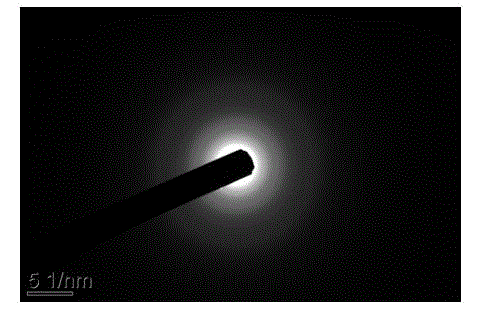

Image

Examples

preparation example Construction

[0021] The present invention proposes a kind of preparation method of monodisperse bismuth nanoparticle, comprises concrete operation steps as follows:

[0022] (1) Add glacial acetic acid to the bismuth source at room temperature, and heat the mixture to 100-180°C to synthesize a bismuth precursor;

[0023] (2) Add oleylamine or oleic acid to the bismuth precursor prepared in step (1), and fully stir evenly. Optionally, add 5–100 mL of octadecene after the stirring step;

[0024] (3) stirring and heating at 100~400° C. to prepare a bismuth nanoparticle solution;

[0025] (4) Centrifuge the solution obtained in step (3) at a speed of 8000 rpm, remove the supernatant and disperse the precipitate in the toluene solution, centrifuge for 5 to 10 times, and finally dissolve the precipitate in toluene , to obtain monodisperse elemental bismuth nanoparticles.

[0026] In the method of the present invention, nitrogen gas is passed into the solution prepared in step (2) before step ...

Embodiment 1

[0030] In this embodiment, oleylamine is used as the encapsulating agent, and the specific steps of the method for preparing monodisperse nanometer elemental bismuth particles of the present invention are as follows:

[0031] (1) At room temperature, add 1 mL of glacial acetic acid to 0.233 g of bismuth trioxide, then heat the mixture to 130°C to synthesize white bismuth acetate, and evaporate the excess acid;

[0032] (2) Add 10 mL of oleylamine to the bismuth precursor (i.e. bismuth acetate) prepared in step (1), and fully stir;

[0033] (3) Into the solution prepared in step (2), feed nitrogen protective gas, stir and heat at 310°C for 4 hours, and add the bismuth nanoparticles under the melting temperature of 285°C to the temperature of low-temperature toluene (temperature-18°C) , 50ml); in this embodiment, the technical effect of preventing oleylamine from being oxidized was achieved by introducing nitrogen protective gas; by adding bismuth nanoparticles into low-temperat...

Embodiment 2

[0037] The present embodiment uses oleic acid as surface-active stabilizer, and its specific steps are as follows:

[0038] (1) Add 1 mL of glacial acetic acid to 0.233 g of bismuth trioxide at room temperature, then heat the mixture to 130°C to synthesize white bismuth acetate, and evaporate the excess acid;

[0039] (2) Add oleic acid to the white bismuth acetate prepared in step (1), the molar ratio of bismuth acetate to oleic acid is 1:3, heat the mixed solution to 130°C and keep it for 3 hours to obtain oleic acid Bismuth; the amount of oleic acid added can also be oleic acid: bismuth precursor molar ratio = 1:6.

[0040] (3) Add 50 mL of octadecene to the solution prepared in step (2), heat at 150° C. for 2 hours, and the heating process is carried out under magnetic stirring to synthesize monodisperse bismuth nanoparticles; in this embodiment, by adding octadecene, The technical effect of controlling the size of bismuth nanoparticles is achieved.

[0041] (4) Centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com