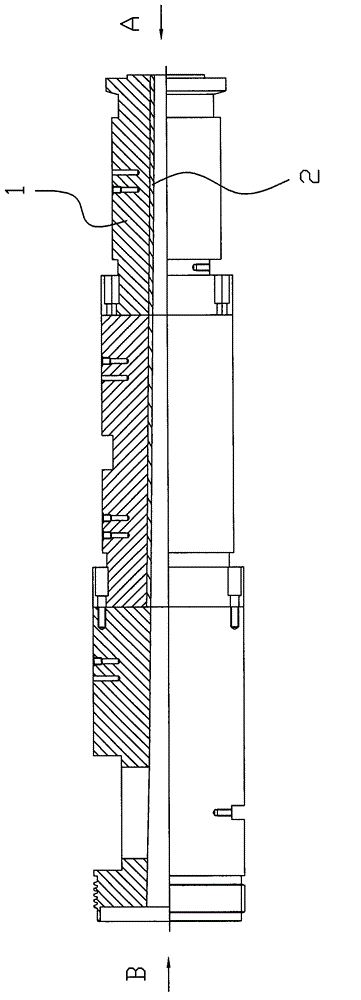

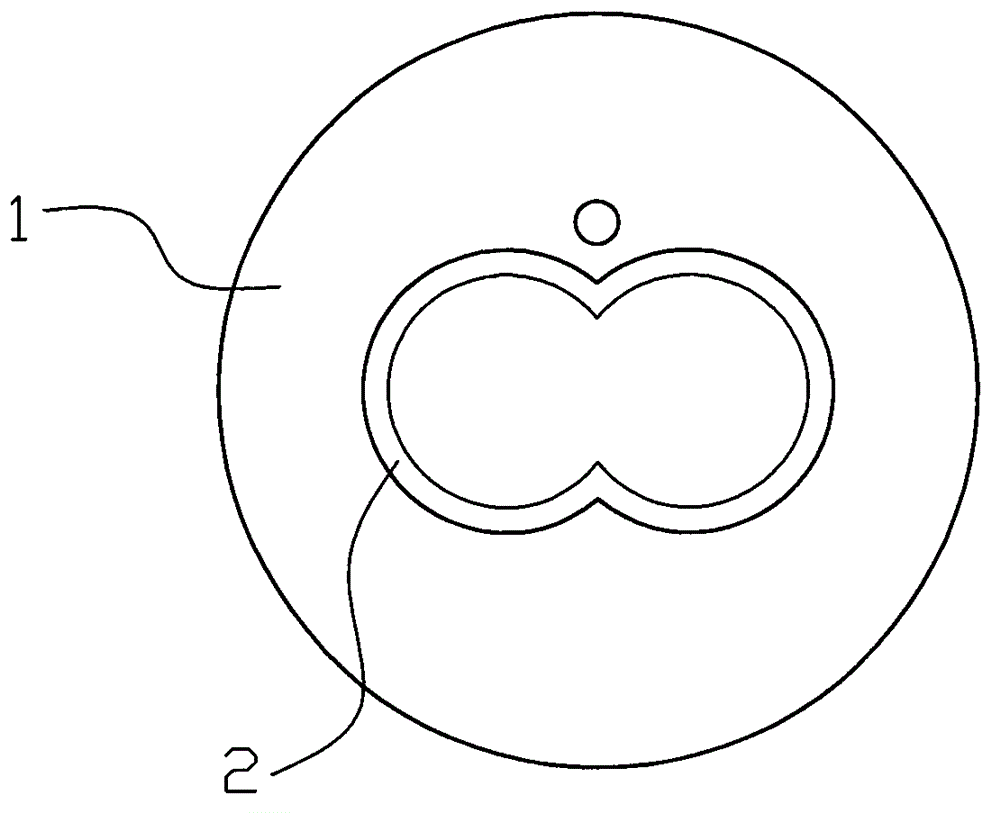

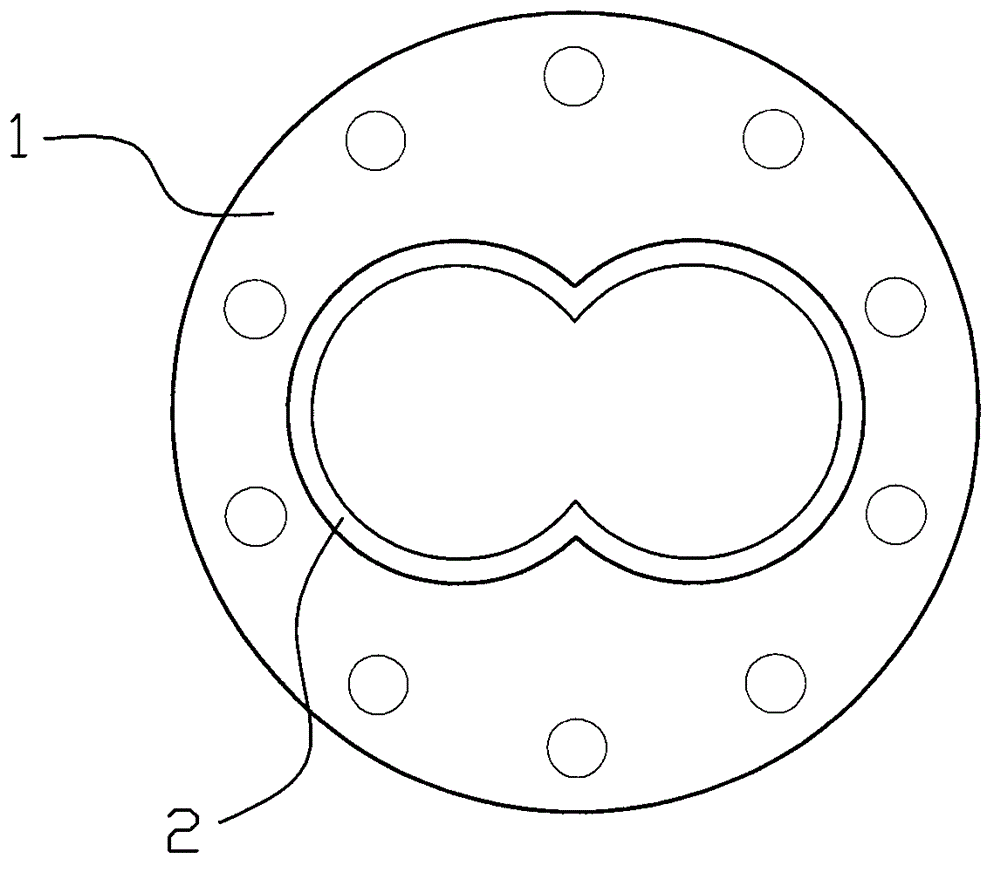

Metal cylinder and manufacturing method thereof

A barrel and metal technology, which is applied in the field of multi-component boride-based superhard bimetallic barrel and its preparation, achieves the effects of good high temperature wear resistance, simple manufacturing process, and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0047] In this embodiment, 40Cr steel is used as the core rod, and a layer of Mo is coated on the surface of the core rod by hot isostatic pressing sintering. 2 FeB 2 -Fe-based cermet layer, and then refined processing to make the barrel. The raw material powders used in the preparation of cermets are pure Mo powder (5-10μm), pure Cr powder (5-10μm), pure Ni powder (5-10μm), pure Fe powder (10-15μm) and FeB powder (20~ 30μm), the mixing ratio is 35% FeB, 45% Mo, 3% Ni, 2% Cr, 15% Fe. The specific preparation method of the bimetal barrel is as follows:

[0048] 1. Put the core rod into the special sheath, and fill the gap between the core rod and the sheath with the mixed raw material powder;

[0049] 2. Put the whole envelope into the sealed container of the hot isostatic pressing equipment and vacuumize;

[0050] 3. The cermet body is prepared by the hot isostatic pressing sintering method, using argon as the pressurizing medium, and the process parameters for controlling the hot ...

Embodiment B

[0057] The preparation of the metal barrel in this example is basically the same as that in Example A, except that the mixing ratio of the raw material powder is changed to: 30% FeB, 50% Mo, 3% Ni, 2% Cr, 15% Fe, and others The experimental conditions are the same. The microhardness test of the cermet of the bimetallic barrel prepared above was carried out, and the average hardness was 1137.5Hv (HRC73).

Embodiment C

[0059] The preparation of the metal barrel in this example is basically the same as that in Example A, except that the mixing ratio of the raw material powder is changed to: 30% FeB, 45% Mo, 3% Ni, 2% Cr, 20% Fe, and others The experimental conditions are the same. The microhardness test was performed on the cermet of the bimetallic barrel prepared above, and the average hardness was 1110.1Hv (HRC72.4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com