Method and device for reduction treatment of residual sludge

A technology for excess sludge and treatment methods, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of increasing the burden of nitrogen and phosphorus pollutants in the process system, affecting the activity of system sludge, and large volume of anaerobic reaction tanks. To achieve the effect of consolidating the effect of sewage treatment, low construction cost and long-term economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

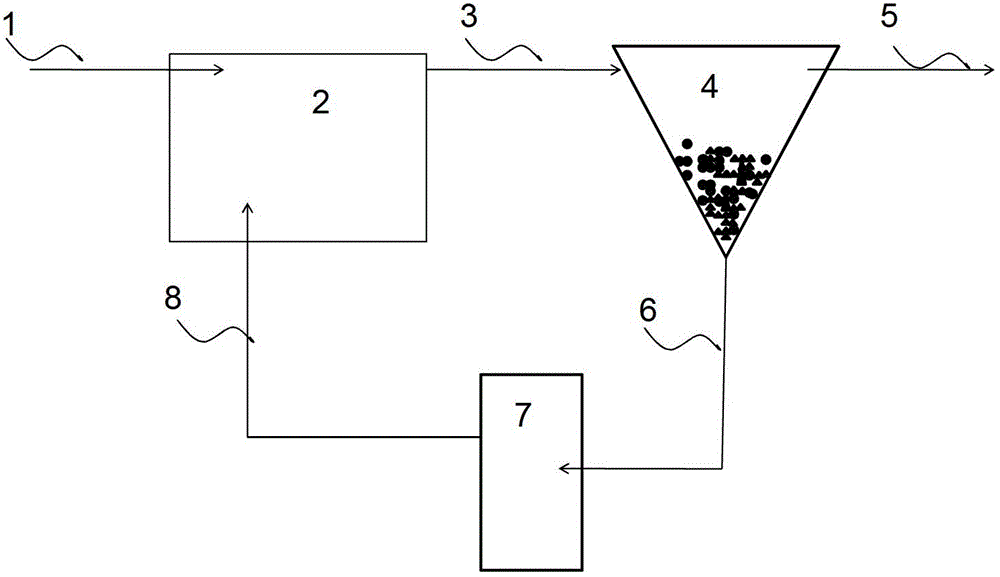

[0031] Example 1 Excess sludge reduction treatment device and method for reducing excess sludge by using the device

[0032] Such as figure 1 As shown, a residual sludge reduction treatment device is composed of an aerobic biochemical reaction tank 2, a sedimentation tank 4 and an anaerobic reaction tank 7, wherein the outlet of the aerobic biochemical reaction tank 2 is connected to the entrance of the sedimentation tank 4, and the sedimentation tank The outlet of 4 is connected with the inlet of anaerobic reaction tank 7, and the outlet of anaerobic reaction tank 7 is connected with the inlet of aerobic biochemical reaction tank 2.

[0033] A method for reducing the amount of excess sludge of the present invention comprises the following steps:

[0034] (1) After the sewage 1 enters the aerobic biochemical reaction tank 2 for sufficient aeration and mixing, the outflow sludge mixture 3 of the aerobic biochemical reaction tank 2 is introduced into the sedimentation tank 4 fo...

Embodiment 2

[0037] Example 2 Effect Research of the Excess Sludge Reduction Treatment Method in Example 1

[0038] This embodiment further illustrates the effect of the method of the present invention through comparative experiments.

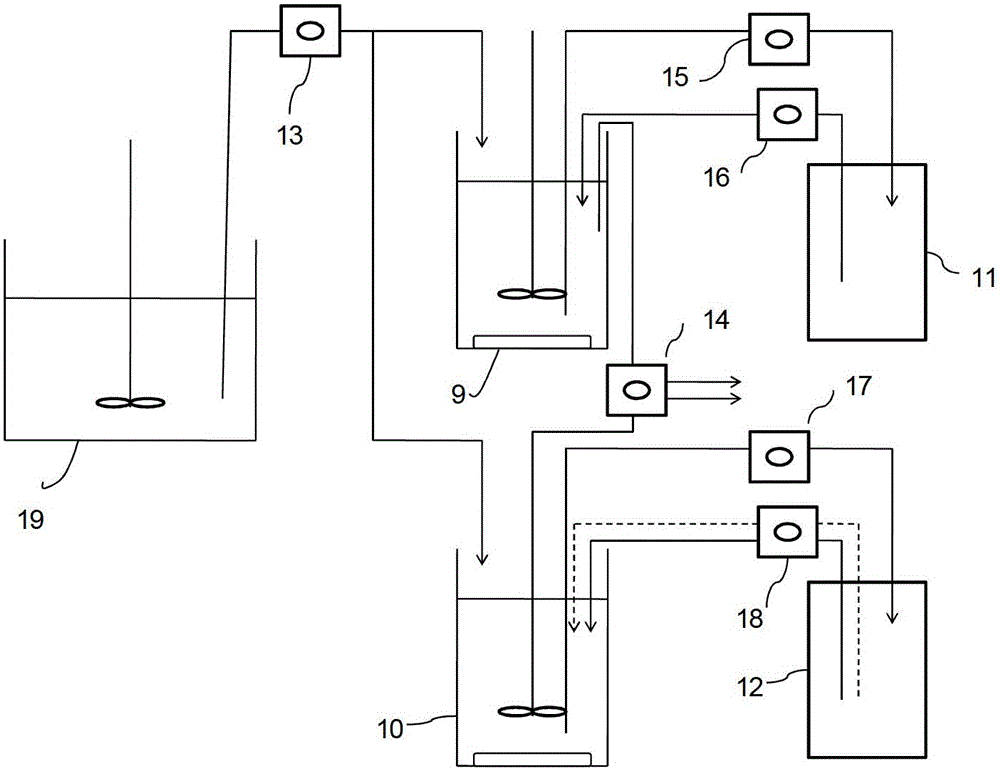

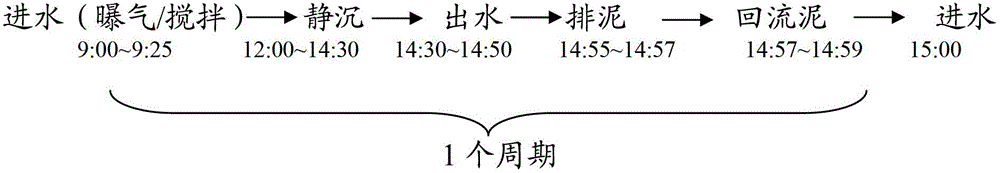

[0039] The excess sludge reduction treatment method of the present invention is based on the SBR-OSA (sequential batch activated sludge process-aerobic-sedimentation-anaerobic) process, without adding any devices, by returning to the anaerobic reaction tank 7. Settling the supernatant, returning to the anaerobic reaction tank every three days. 7. The operation mode of mixed sludge replaces the traditional operation mode of returning mixed sludge, forming a new SBR-OSA process, in order to pass the return of the static settling supernatant Liquid reduces the impact of reflux on the aerobic biochemical reaction tank 2, and improves the sewage treatment performance of the system; at the same time, it is also hoped that this improved operation mode will further s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com