Priming paint with absorption resistance, preparation method and application

A primer and unsaturated technology, applied in the direction of polyester paint, coating, etc., can solve the problem that the performance is not completely excavated, and achieve the effect of excellent gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

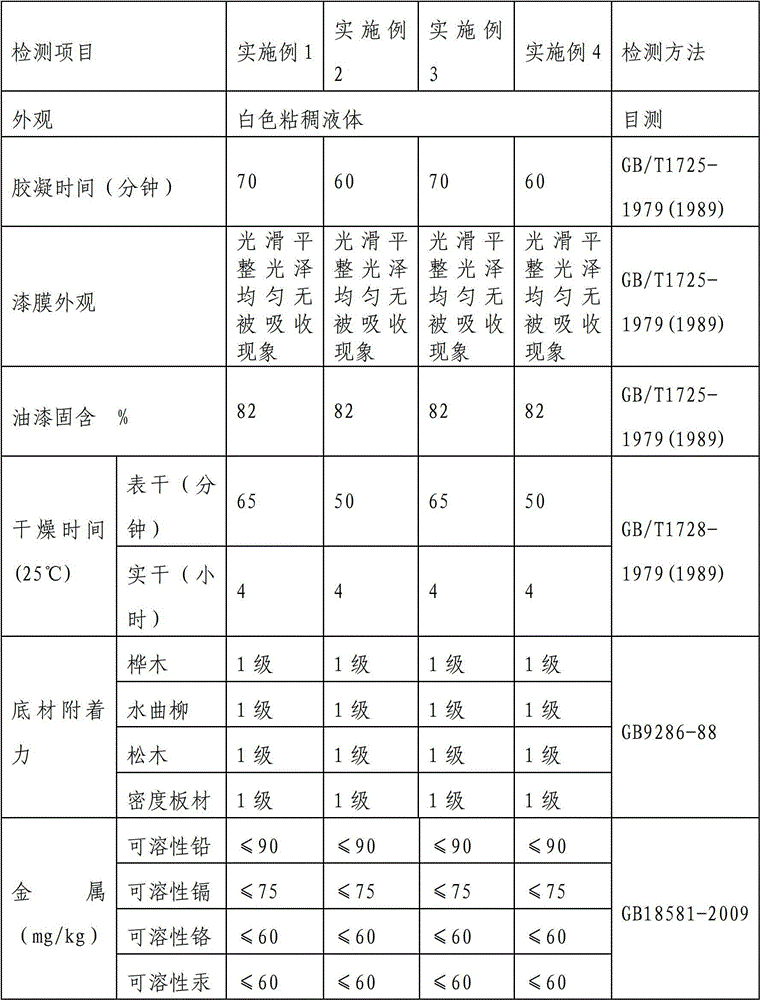

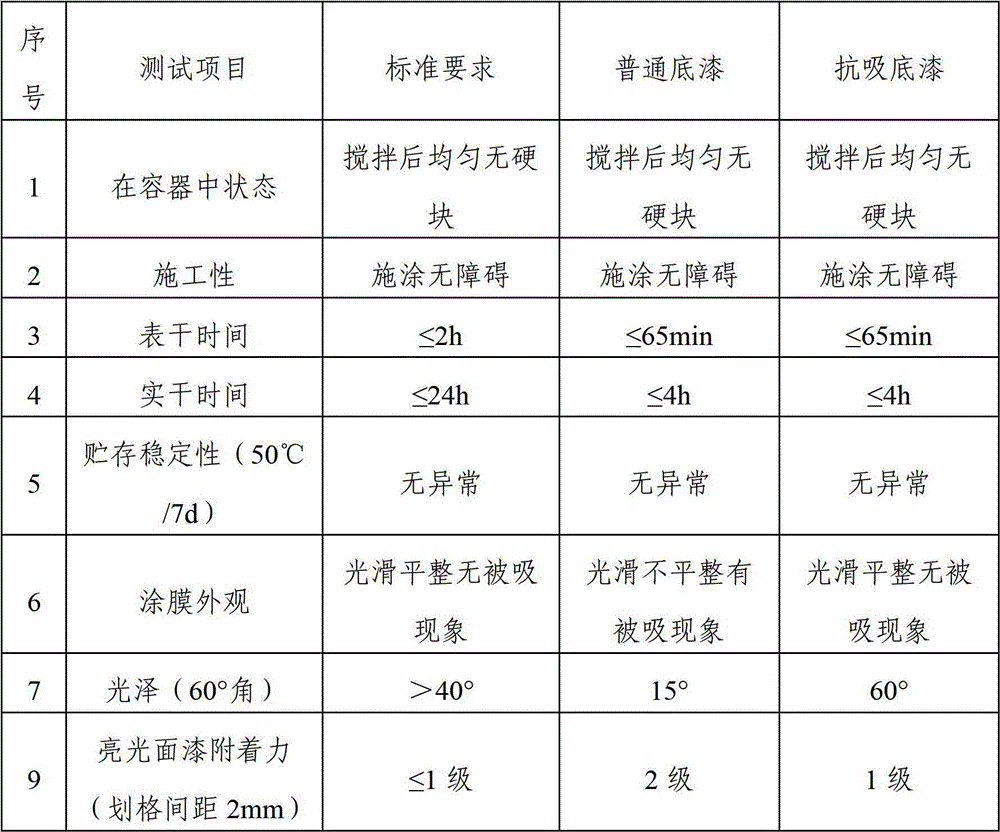

Examples

Embodiment 1

[0039] A kind of anti-absorption primer that is used as bright finish paint in summer, described anti-absorption primer comprises following A, B, C, D four components:

[0040] A component:

[0041] 50kg allyl ether modified dicyclopentadiene type unsaturated polyester resin (produced by Changzhou Fangxin Chemical Materials Co., Ltd., FX-8309), 0.816kg styrene and 0.1kg defoamer (produced by BYK Company of Germany, BYK8801), 0.1kg wetting and dispersing agent (produced by German BYK company, BYK104), 0.02kg polymerization inhibitor (produced by Changzhou Fangxin Chemical Materials Co., Ltd., hydroquinone), 0.2kg leveling agent (produced by German BYK company , BYK358N) mix evenly, stir for 5 to 15 minutes;

[0042] (2) Slowly add 10kg of heavy calcium carbonate (produced by Jiangxi Guangyuan Chemical Co., Ltd., CC-800), 22kg of talcum powder (produced by Guangxi Longsheng Huamei Talc Development Co., Ltd., 1000 mesh), 0.3kg of anti-settling agent (Germany Produced by Degussa...

Embodiment 2

[0050] A kind of anti-suction primer used as gloss finish paint in winter, described anti-absorption primer comprises following A, B, C, D four components:

[0051] Preparation of component A:

[0052]40kg allyl ether modified dicyclopentadiene type unsaturated polyester resin (produced by Shenzhen Zhanchen Group, JD3309), 1.284kg styrene and 0.1kg defoamer (produced by BASF, Germany, EFKA2720), 0.1kg wet Dispersant (BYK104 produced by BYK, Germany), 0.02kg polymerization inhibitor (hydroquinone), 0.2kg leveling agent (EFKA3777 produced by BASF, Germany) were mixed evenly, and stirred for 5-15min;

[0053] (2) Slowly add 20kg talcum powder (produced by Guangxi Guilin Superfine Powder Co., Ltd., TP1250), 20kg heavy calcium carbonate (produced by Jiangxi Guangyuan Chemical Co., Ltd., CC-800), 0.3kg anti-settling agent (Germany Degu Sa company production, A-200), 10kg pigment (DuPont Chemical Group production, DuPont R-706), 5kg grinding agent (Bai Lihe Chemical Co., Ltd. produc...

Embodiment 3

[0061] A kind of anti-absorption primer that is used as matte finish paint in summer, described anti-absorption primer comprises following A, B, C, D four components:

[0062] Preparation of component A:

[0063] 45kg allyl ether modified dicyclopentadiene type unsaturated polyester resin (produced by Changzhou Fangxin Chemical Materials Co., Ltd., FX-8309), 0.618kg styrene and 0.2kg defoamer (produced by BASF, Germany, EFKA2720), 0.2kg wetting and dispersing agent (manufactured by BASF, EFKA 8605), 0.01kg inhibitor (hydroquinone), 0.1kg leveling agent (manufactured by Huaxia Chemical Industry Group, HX-3130) mixed evenly, and stirred 5~15min;

[0064] (2) Slowly add 18kg talcum powder (produced by Guangxi Guilin Superfine Powder Co., Ltd., TP1250), 20kg heavy calcium carbonate (produced by Jiangxi Guangyuan Chemical Co., Ltd., CC-800 heavy calcium carbonate), 0.4kg anti-sedimentation agent (produced by Deqian Chemical Co., Ltd., bentonite CD-1), 8kg of pigment (produced by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com