A kind of preparation method of aluminum-containing tannin

A technology of tannin and aluminum salt, applied in the field of tanning, can solve the problems of unsatisfactory light resistance and low solid content of the product, achieve high development value and application prospects, good filling performance, and improve the effect of poor parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

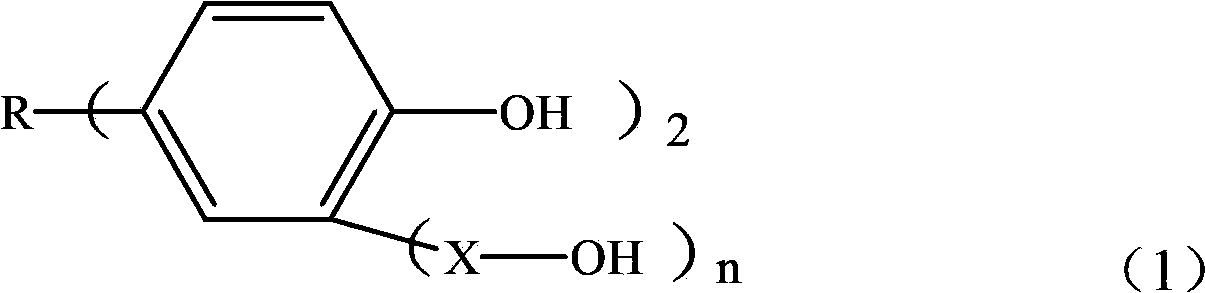

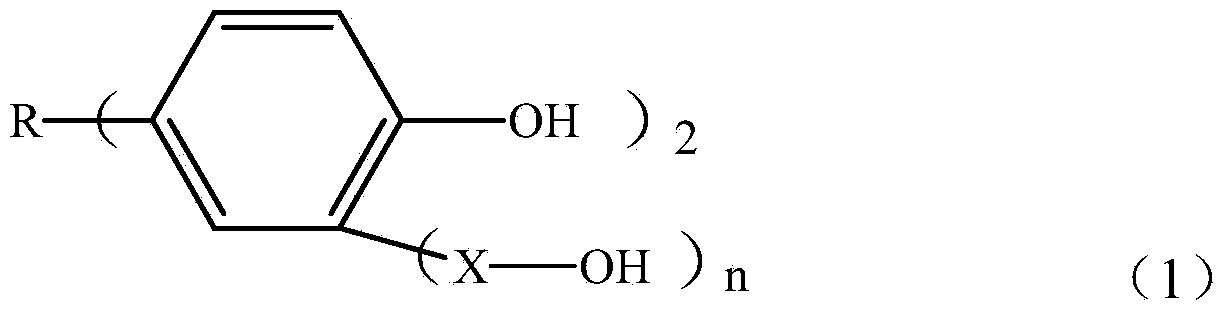

Method used

Image

Examples

Embodiment 1

[0016] The first step: 5.3 parts of Na by mass parts 2 CO 3 Mix with 99.9 parts of aluminum sulfate octadecahydrate, then control the temperature at 55 ° C for 2 hours, then add 11.8 parts of succinic acid (masked ligand) and react for 1 hour to obtain masked modified aluminum with a basicity of 11%. Salt, Al in aluminum salt 2 o 3 The content is 9.3%;

[0017] The second step: 32.3 parts of synthetic tannin MND5901 containing bisphenol S structure (the main structure is the condensate of aromatic sulfone bridge compound and naphtholsulfonic acid condensation) is mixed with 54.8 parts of aluminum salt according to the number of parts, and then the temperature is controlled at React at 60°C for 1 h, add sulfuric acid after the reaction to adjust the pH to 3, and obtain the target product. The target product can be used for direct tanning and deliming naked goatskin, and the consumption of product (in Al 2 o 3 Calculated) is 3% of the mass of bare leather. After aging the ...

Embodiment 2

[0019] The first step: 5.3 parts of Na by mass parts 2 CO 3 Mix it with 66.6 parts of aluminum sulfate octadecahydrate, then control the temperature and react at 60°C for 1.5h, then add 13.2 parts of glutaric acid (masked ligand) and react for 1h to obtain the Aluminum salt, Al in aluminum salt 2 o 3 The content is 8.8%;

[0020] The second step: mix 32.3 parts of synthetic tannin MND5901 containing bisphenol S structure (the main structure is the condensate of aromatic sulfone bridge compound and naphthol sulfonic acid condensation) with 58 parts of aluminum salt in parts by mass, and then control the temperature at React at 50°C for 1.5h, add hydrochloric acid after the reaction to adjust the pH to 3, and obtain the target product. The target product can be used for direct tanning and deliming naked goatskin, and the consumption of product (in Al 2 o 3 Calculated) is 3% of bare leather quality, and the leather after tanning is aged for one day, and its shrinkage temper...

Embodiment 3

[0022] The first step: 5.3 parts of Na by mass parts 2 CO 3 Mix with 66.6 parts of aluminum sulfate octadecahydrate, then control the temperature and react at 65°C for 1 hour, then add 14.6 parts of adipic acid (masked ligand) and react for 1 hour to obtain masked modified aluminum with a basicity of 33%. Salt, Al in aluminum salt 2 o 3 The content is 7.8%;

[0023] The second step: 32.3 parts of synthetic tannin MND5901 containing bisphenol S structure (the main structure is the condensate of aromatic sulfone bridge compound and naphtholsulfonic acid condensation) is mixed with 66.2 parts of aluminum salt according to the number of parts, and then the temperature is controlled at React at 55°C for 1.2h, add formic acid after the reaction to adjust the pH to 3, and obtain the target product. The target product can be used for direct tanning and deliming naked goatskin, and the consumption of product (in Al 2 o 3 Calculated) is 3% of bare leather quality, and the leather ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com