Method for recycling heavy metal in electroplating sludge

A technology for electroplating sludge and recycling, which can be used in the improvement of process efficiency, photography technology, instruments, etc., and can solve problems such as undisclosed manganese.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (Example 1, resource recycling of copper in electroplating sludge)

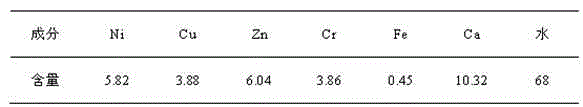

[0046] The electroplating sludge treated in this example is taken from the electroplating factory, and its appearance is gray, and the copper content is the majority. As the copper-containing electroplating sludge, the water content is about 70%. The various metal components in the electroplating sludge are shown in Table 1.

[0047] Table 1 The contents of various metals in electroplating sludge mg / g

[0048]

[0049] The method for resource recycling of electroplating sludge comprises the following steps:

[0050] ① Pretreatment of electroplating sludge. Centrifuge and dehydrate the electroplating sludge to be treated. After dehydration, the moisture content of the sludge is 30% to 40%. In the embodiment, it is a sieve of 300 mesh), and sieve to remove large particles and large sand particles; collect the sieved sludge, place it in an oven and dry it at 105°C until the sludge has a constant wei...

Embodiment 2

[0089] (Example 2, resource recovery of nickel in electroplating sludge)

[0090] The electroplating sludge treated in this example is taken from the electroplating factory, and its appearance is reddish brown. Compared with the usual electroplating sludge, the nickel content is in the majority, and the nickel content is greater than 5%. As nickel-containing electroplating sludge, the total content of various metals is 30.37 wt%, and the moisture content is about 68wt%. The various metal components in the electroplating sludge are shown in Table 2. in,

[0091] Table 2 The wt% of various metals in nickel-containing electroplating sludge

[0092]

[0093] The method for resource recycling of electroplating sludge comprises the following steps:

[0094] ① Pretreatment of electroplating sludge. The nickel-containing electroplating sludge to be treated is centrifugally dehydrated, and the moisture content of the sludge after dehydration is 30% to 40%; the sludge after centr...

Embodiment 3

[0123] (Example 3, resource recycling of copper in electroplating sludge)

[0124] The electroplating sludge treated in this embodiment is the same as that treated in Example 1.

[0125] All the other methods of electroplating sludge recycling are the same as in Example 1, except that:

[0126] In step ③, the cells of Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Heteroxia bacteria are mixed evenly at a mass ratio of 2:2:1, then added to the culture solution, and then the electroplating prepared in step ① The sludge powder is added to the culture solution to obtain the reaction mixture material. The concentration of electroplating sludge in the reaction mixture material is 20-40g / L (30g / L in this embodiment); the inoculum concentration of Thiobacillus ferrooxidans is 10 8 individual / mL, the inoculum concentration of Thiobacillus thiooxidans is 10 8 individual / mL, the inoculum concentration of heterooxygen bacteria was 10 8 individual / mL.

[0127] The Thiobacillu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com