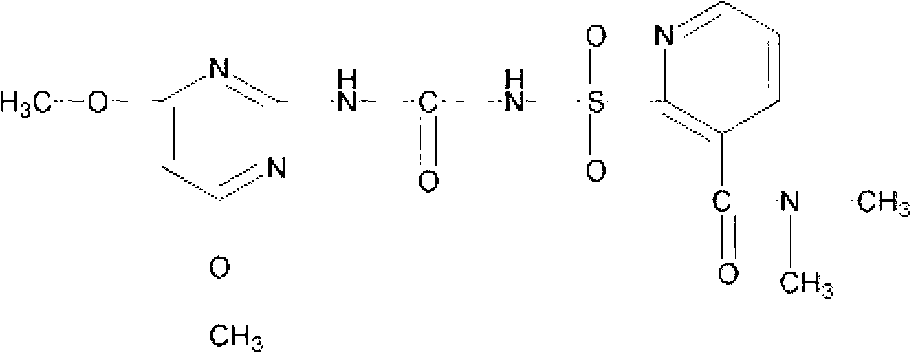

Nicosulfuron soluble granule and preparation method thereof

A nicosulfuron and soluble technology, applied in the field of nicosulfuron soluble granules and its preparation, can solve the problems of reducing drug efficacy, low content of active ingredients, and large dosage, so as to save packaging and transportation Cost and storage space, increase the content of active ingredients, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

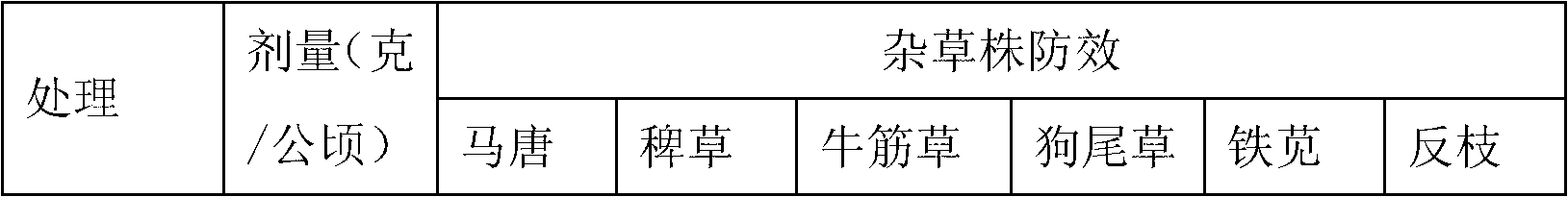

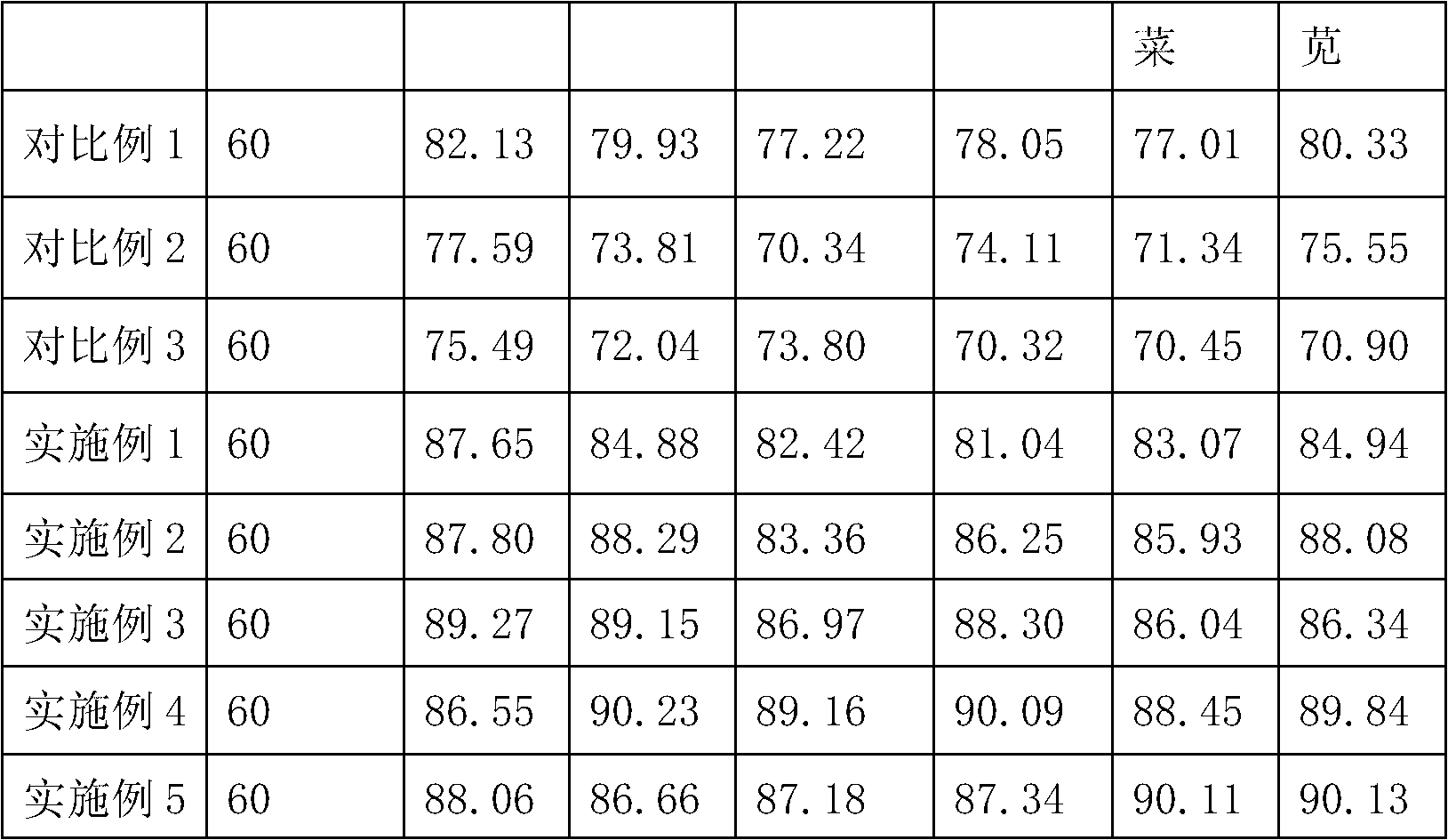

Examples

Embodiment 1

[0040] Composition and weight: 95% pure nicosulfuron original drug 31.6kg, basic compound sodium carbonate 5kg, wetting and dispersing agent calcium lignosulfonate and sodium lauryl sulfate, 5kg and 1.5kg respectively, Penetrant fatty alcohol polyoxyethylene ether 10kg, filler sodium sulfate 46.9kg.

Embodiment 2

[0043] Composition and weight: 42.1kg of nicosulfuron original drug with a purity of 95%, basic compounds sodium carbonate and sodium bicarbonate, 5kg and 2kg respectively, wetting and dispersing agent methyl naphthalene sulfonic acid formaldehyde condensate sulfate and Sodium dodecylbenzene sulfonate, 8kg and 2kg respectively, penetrant sulfonated dioctyl succinate sodium salt 8kg, filler urea 34.9kg.

Embodiment 3

[0046] Composition and weight: 95% pure nicosulfuron original drug 52.7kg, basic compounds sodium bicarbonate and sodium hydroxide, 8kg and 2kg respectively, wetting and dispersing agent sodium methylene naphthalene sulfonate dibutyl Nasylsulfonic acid-formaldehyde condensate and pull open powder are respectively 6kg and 1.5kg, penetrant laurin 3kg, filler sodium chloride 26.8kg.

[0047] Anhydrous ethanol: 10kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com