Micro powder fine powder dry-type magnet separator

A magnetic separator and fine powder technology, applied in the field of magnetic separator, can solve the problems of ineffective separation of fine powder and fine powder, high mineral recovery rate, and high separation purity, and achieve high mineral recovery rate and high separation efficiency , Select the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

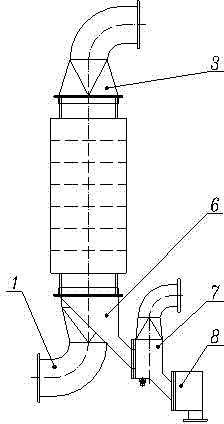

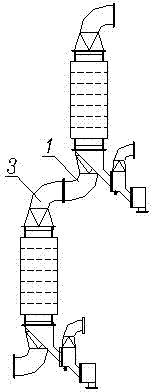

[0039] like image 3 As shown, the air outlet pipe 3 of one magnetic separator main body is connected to the air inlet pipe 1 of another magnetic separator main body, forming a series structure. The main bodies of multiple magnetic separators can be connected in series to form multiple magnetic separations to obtain better magnetic separation effects.

Embodiment 2

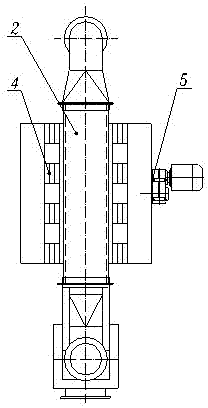

[0041] like Figure 4 and Figure 5 Shown:

[0042] When in use, the mode of arraying magnetic separators in a matrix can also be adopted to add an air collecting pipe 11 and an air distribution pipe 10. The air distribution pipe 10 can divide a nozzle into multiple interfaces, and the air collecting pipe 11 can Combines multiple interfaces into one nozzle. The air collecting pipe 11 is connected to the air outlet pipe 3 , and the air distribution pipe 10 is connected to the air inlet pipe 1 . Arrange several magnetic separator bodies in a matrix, such as arranging 9 magnetic separator bodies in a 3x3 array, then connect the outlet pipes 3 of the 9 magnetic separator bodies with the manifold 11, and connect the 9 The air inlet pipe 1 of each magnetic separator body is connected with the air distribution pipe 10.

[0043] The air distribution pipe is connected to the large amount of gas provided by the high-pressure roller mill system after roller pressure separation, and s...

Embodiment 3

[0045] When in use, a magnetic separator combined in series and matrix arrangement can also be used. The air outlet pipe 3 of the main body of a magnetic separator is connected with the air inlet pipe 1 of the main body of another magnetic separator to form a series structure. Several The main body of the magnetic separator is arranged in a matrix array after being connected in series.

[0046] In this way, a better magnetic separation effect can be obtained and the processing capacity of the magnetic separator can be enhanced at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com