Method and device for preparing boehmite powder by using esterification reaction hydrothermal method

A boehmite powder, esterification technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of long reaction time, low production efficiency and high reaction temperature of hydrothermal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

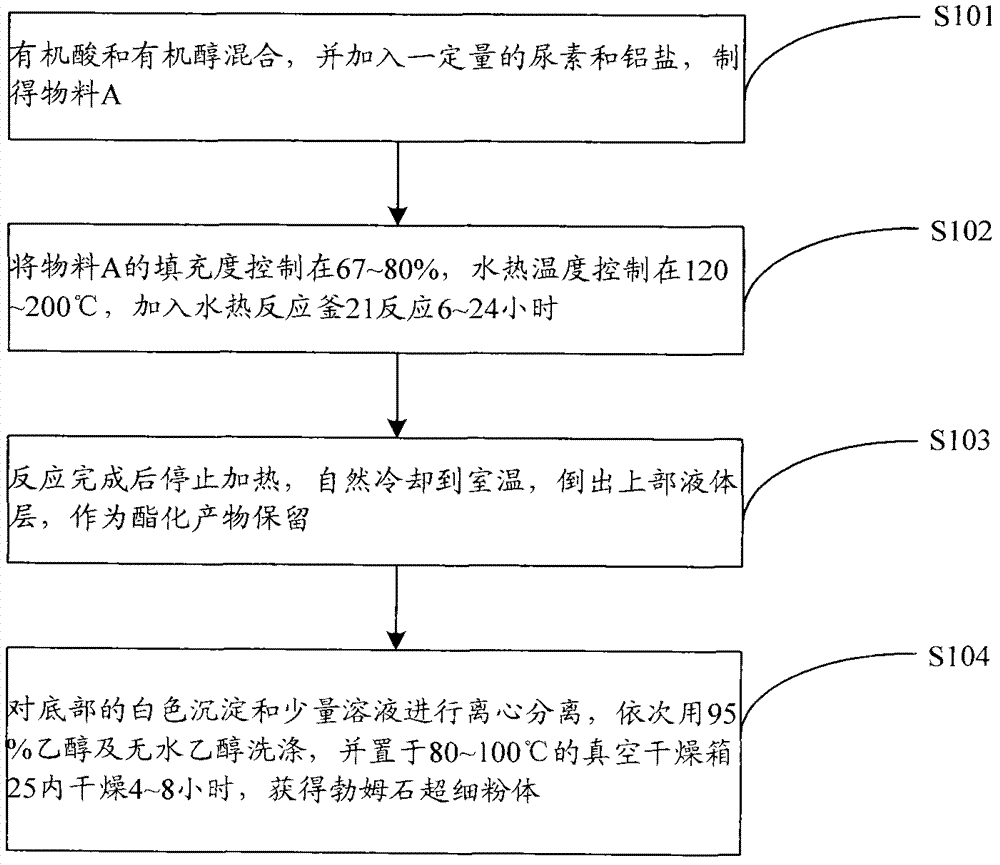

Method used

Image

Examples

Embodiment 2

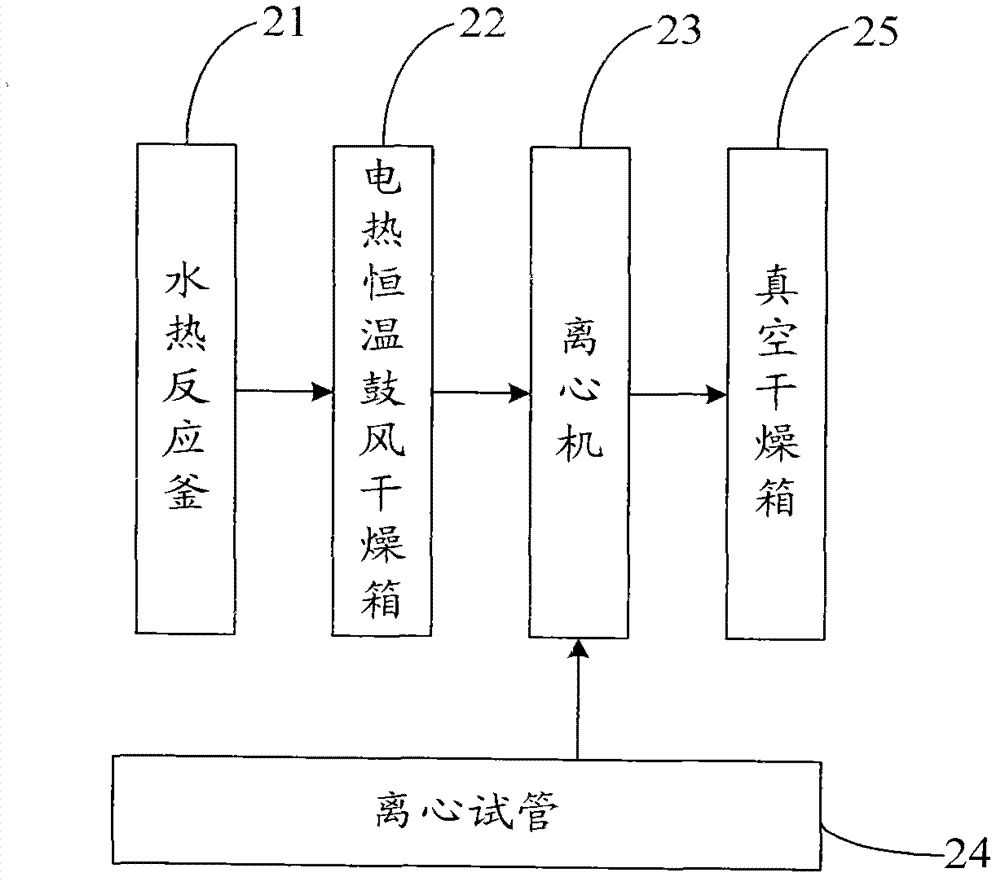

[0046] Embodiment 2: at first, the dehydrated alcohol of 30ml (0.5mol) glacial acetic acid and 50ml is joined in the liner in the hydrothermal reaction kettle 21, the theoretical water yield of the esterification reaction of the present embodiment is 0.5mol, i.e. 9 grams, Considering the solubility of aluminum nitrate in water, and properly leaving a surplus, so adding 0.01 mole of aluminum nitrate and 0.02 mole of urea, the degree of filling in the hydrothermal reactor 21 is controlled at 80%, and the sealed hydrothermal reactor 21, Put it in the electric heating constant temperature blast drying box 22, control the hydrothermal temperature at 180°C, react for 18 hours, and naturally cool to room temperature after the reaction; finally open the hydrothermal reaction kettle 21, and pour out the upper liquid layer of the inner tank , remain as the esterification product; then, pour the white precipitate and a small amount of solution at the bottom into the centrifugal test tube ...

Embodiment 3

[0047] Embodiment 3: at first, the dehydrated alcohol of 30ml (0.5mol) glacial acetic acid and 50ml is joined in the liner in the hydrothermal reaction kettle 2l, and the theoretical water output of present embodiment esterification reaction is 0.5mol, i.e. 9 grams, Considering the solubility of aluminum chloride in water, and properly leaving a surplus, so add 0.015 moles of aluminum chloride and 0.03 moles of urea, the filling degree in the hydrothermal reaction kettle 21 is controlled at 80%, and the sealed hydrothermal reaction kettle 21. Put it in the electric heating constant temperature blast drying oven 22, control the hydrothermal temperature at 160°C, react for 12 hours, and naturally cool to room temperature after the reaction; finally open the hydrothermal reaction kettle 2l, and remove the upper liquid layer of the inner tank Pour it out and keep it as an esterification product; then, pour the white precipitate and a small amount of solution at the bottom into a ce...

Embodiment 4

[0048] Embodiment 4: at first, the dehydrated alcohol of 45ml (0.6mol) propionic acid and 35ml is joined in the liner in the hydrothermal reaction kettle 21, and the theoretical water yield of the esterification reaction of the present embodiment is 0.6mol, namely 10.8 grams, Considering the solubility of aluminum chloride in water, and appropriately leaving a surplus, so add 0.02 mole of aluminum chloride and 0.04 mole of urea, the filling degree in the hydrothermal reactor 2l is controlled at 80%, and the sealed hydrothermal reactor 21. Place it in an electric heating constant temperature blast drying oven 22, control the hydrothermal temperature at 150°C, react for 24 hours, and cool to room temperature naturally after the reaction; finally open the hydrothermal reaction kettle 21, and remove the liquid layer on the upper part of the liner. Pour it out and keep it as an esterification product; then, pour the white precipitate and a small amount of solution at the bottom into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com