Rubber composition for tire and tire using same

A technology for rubber compositions and tires, applied in special tires, tire parts, tire edges, etc., can solve the problems of increased tire weight, lack of disclosure, and deterioration of operational responsiveness, and achieve excellent crack growth resistance and separation resistance. Excellent properties and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22 and comparative example 1~14

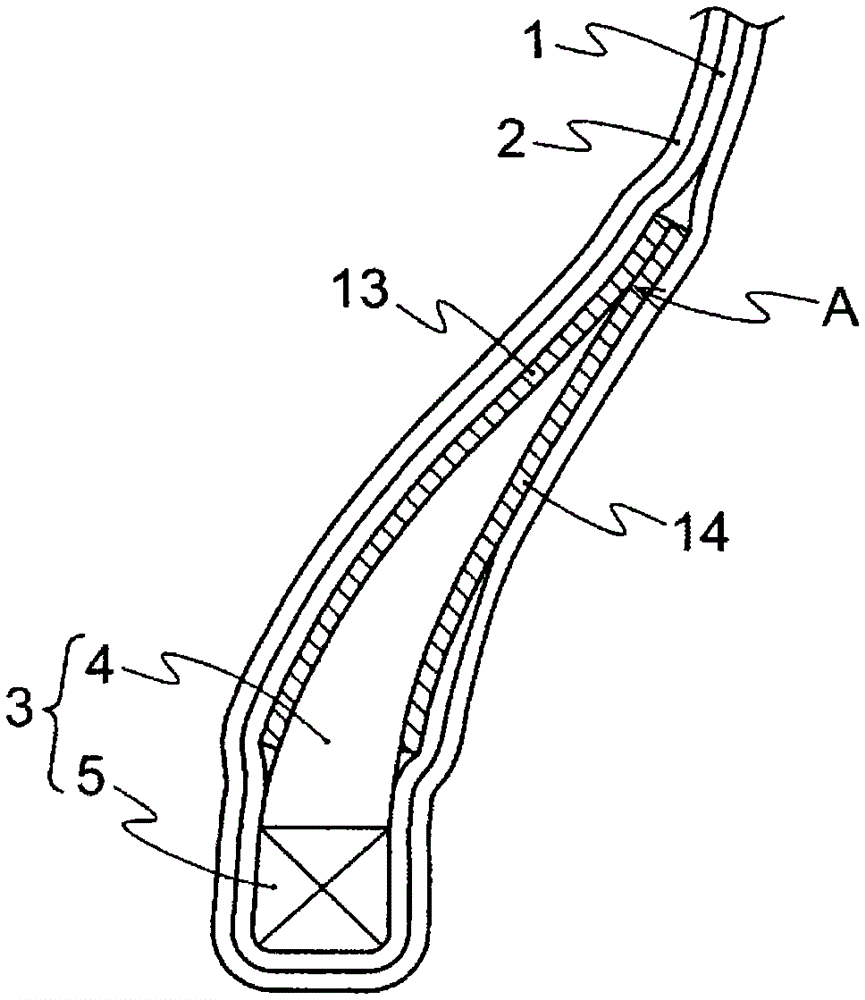

[0170] In the formulation content shown in Table 1 and Table 2, various chemicals except insoluble sulfur and vulcanization accelerator were kneaded with a Banbury mixer. The resulting kneaded product was discharged at 180°C, to which insoluble sulfur and a vulcanization accelerator were added, kneaded in an open roll, and discharged at 105°C, whereby an unvulcanized rubber composition was obtained. Test pieces were prepared by vulcanizing the unvulcanized rubber composition at 170° C. for 12 minutes, and the following tests were performed using the obtained test pieces. Furthermore, the above-mentioned unvulcanized rubber composition was molded with a single rubber extruder into image 3 The shape of the apex strip shown (average thickness: 1.0mm, h1: 60, h2: 15 for the apex strip 13, h1: 60, h2: 15 for the apex strip 14) should be attached to other tire components Unvulcanized tires were combined and press-vulcanized at 150° C. for 35 minutes to manufacture test tires (size...

Embodiment 23 and 24

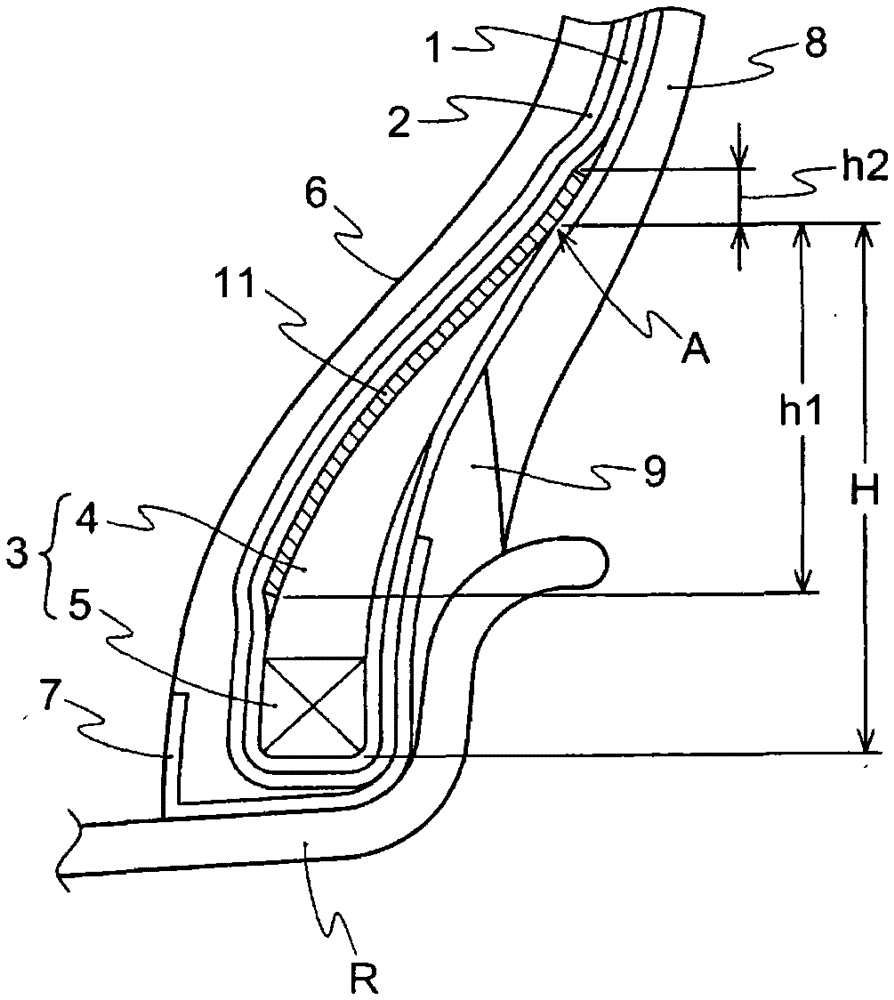

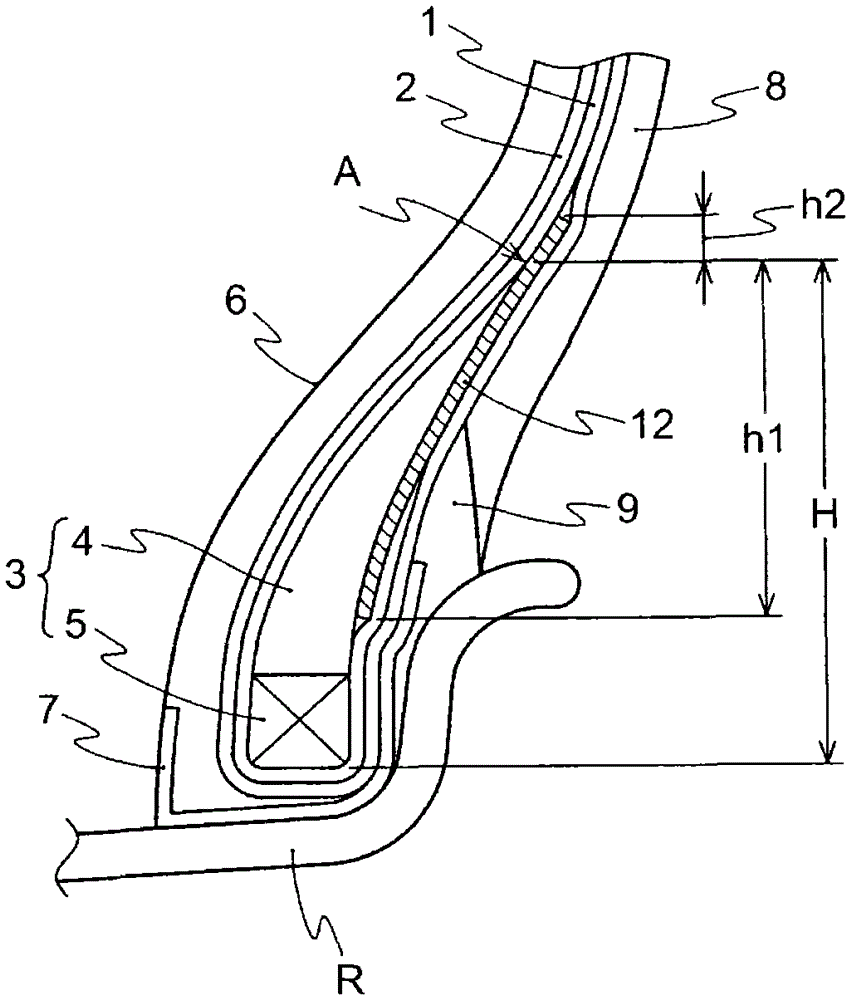

[0172] In order to make the unvulcanized rubber composition Figure 5 (Example 23) and Figure 9The bead apex of the two-layer structure shown in (Example 24) was produced in the same manner as in the above-mentioned Example 1, except that the unvulcanized rubber composition of the bead apex formulation was molded with a double-two-layer extruder. The test tires were subjected to the tests shown below.

[0173]

[0174] The prepared test piece was cut into width 4mm, length 40mm, and thickness 2mm, and measured the complex modulus of elasticity (E * ) and loss tangent (tanδ) viscoelastic properties. The measurement conditions were: initial strain 10%, dynamic strain 2%, vibration frequency 10 Hz, temperature 70°C. E. * The value of α is 4 to 8 MPa, showing excellent driving stability and separation resistance (strain dispersibility). In addition, the smaller the value of tan δ, the better the low heat build-up property.

[0175]

[0176] According to JIS K6251, a ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com