High CTI (Comparative Tracking Index) flame retardant glass fiber reinforced PA66 (Polyamide 66)/PE (Polyethylene) alloy composite and preparation method thereof

A technology of PA6620 and composition, which is applied in the field of high CTI value flame-retardant glass fiber reinforced PA66/PE alloy composition and its preparation, which can solve the restrictions on the use of flame retardants, reduce the mechanical properties of materials, electrical insulation properties, and require hysteresis, etc. problems, to achieve short residence time, improve oxidation resistance, and reduce friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

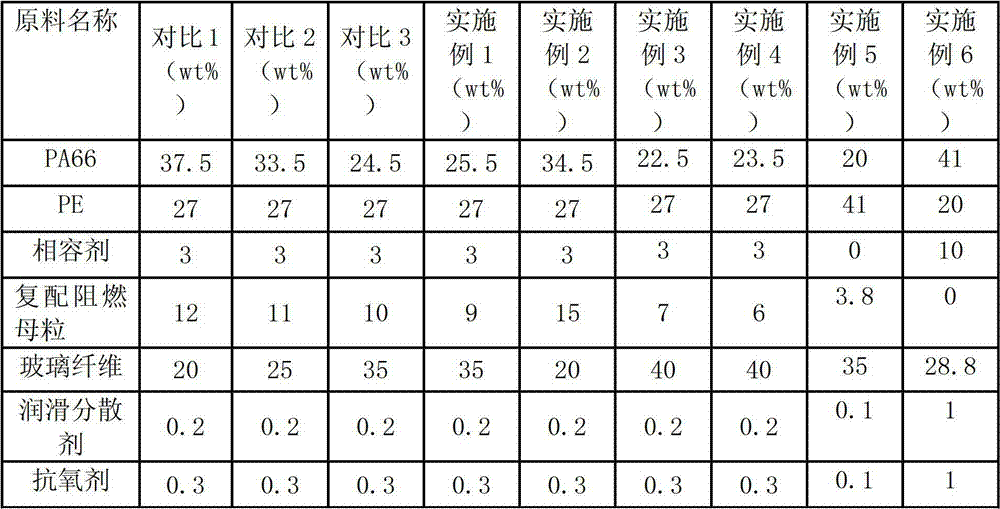

[0028] The raw materials of Examples 1 to 6 and their weight percent content are shown in Table 1; the raw materials are weighed according to the above weight percentage content; put into a high mixer and mix for 2 to 5 minutes, discharge, and then extrude with a twin-screw Extruded and granulated by machine to produce high CTI value and low segregation flame retardant glass fiber reinforced PA66 / PE alloy composition, wherein the processing temperature is 225-245°C and the screw speed is 30-40Hz; the specific processing conditions are shown in the table 2.

[0029] In Table 1, the melt index of PE is 0.5-20 grams per cubic centimeter, and PA66 is polyamide 6 with an intrinsic viscosity of 2.4 dL / g. The compound flame retardant masterbatch is made by mixing the following components by weight percentage: iron-removing red phosphorus masterbatch: 50%; anti-migration agent: 25%; high CTI additive: 25%, using compound flame retardant masterbatch Compared with the traditional flame...

Embodiment 5

[0034] Embodiment 5, performance test

[0035] The performance test and comparison of the high CTI value and low precipitation flame-retardant glass fiber reinforced PA66 / PE alloy compositions prepared in the above Comparative Examples 1-3 and Examples 1-6 were carried out according to the ASTM standard. The test performance comparison is shown in Table 3:

[0036] table 3

[0037]

[0038] It can be concluded from Table 3 that compared with Comparative Examples 1-3, the materials prepared in Examples 1-6 have better tensile strength, flexural strength, flexural modulus and impact strength. The composition of the invention has high CTI value, low precipitation, environmental protection and balanced comprehensive performance, can be widely used in the fields of electronic appliances such as contactors, circuit breaker shells, etc., and has good application prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com