Free-cutting steel part and manufacturing method thereof

A technology of free-cutting steel and manufacturing methods, which is applied in the direction of coating, layered products, metal material coating technology, etc., and can solve the problems of uneven surface hardness of free-cutting steel parts and the inability to achieve surface properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

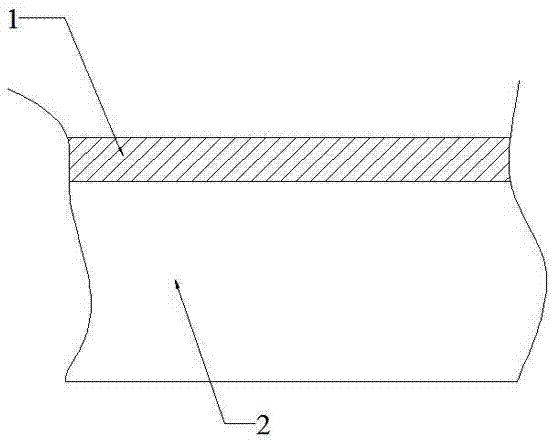

[0032] refer to image 3 As shown, a free-cutting steel part of the present invention mainly includes two parts, a matrix and a strengthening layer, wherein the strengthening layer is formed by post-heat treatment of the matrix.

[0033] Specifically, the matrix component and structure are equivalent to carbon steel containing free-cutting elements, that is, equivalent to the untreated free-cutting steel billet itself, so it can inherit the excellent performance of free-cutting steel itself, making the present invention Free-machining steel parts have better internal strength and toughness.

[0034] As a preferred solution, the free-machining elements in the matrix include: one or more of sulfur, phosphorus, and lead.

[0035] refer to Figure 4 with Figure 5 , we can see that the strengthening layer of the present invention contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com