Post-processing control unit for ammonia storage and supply in two-stage waste heat mode

A technology for ammonia storage, ammonia supply, and control unit, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, engine components, etc. It can solve problems such as no clear instructions, technical personnel can’t implement, and no increase ratio, etc., to achieve full usability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

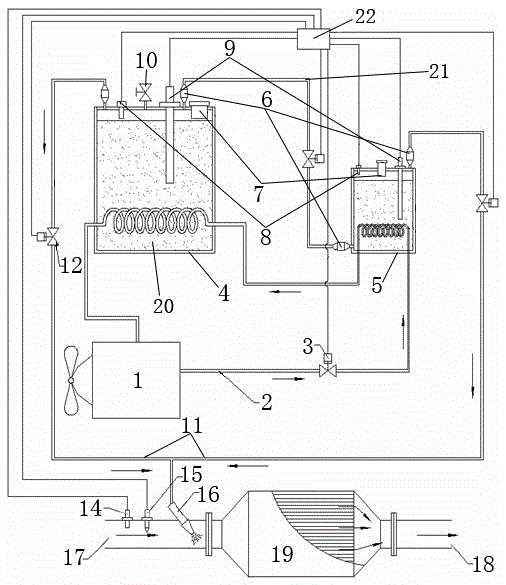

[0025] The preparation and filling method of the described solid ammonia storage material 20 are as follows: adopt 58 parts of industrial anhydrous magnesium chloride, 2 parts of expanded graphite, 15 parts of deionized water, 10 parts of industrial ethanol and 15 parts of industrial ball clay. The noodle mixer mixes evenly to become wet powder, and the mixing time is 5-15 minutes. Fill it into the main ammonia storage tank 4 and the auxiliary ammonia storage tank 5 through the feeding port 7, and use the mechanical vibration method to vibrate the main ammonia storage tank 4 and the auxiliary ammonia storage tank 5. Auxiliary ammonia storage tank 5 tank body 5~10min, remove the air gap in it, the amount of feed should be 40% of the volume capacity of the tank body; put the whole tank body in a vacuum oven, start heating from room temperature 25°C under normal pressure, Average 5°C / 10min, heat up to 70°C, open the feeding port 7 during heating and drying, and discharge water vap...

Embodiment

[0028] In order to ensure the safety of the system under relatively high pressure, the main ammonia storage tank 4 is a pressure-resistant tank made of stainless steel. Insulation; the preparation sequence of the main ammonia storage tank 4 and the auxiliary ammonia storage tank 5 is to weld the tank body into a cylindrical shape first, and thermally spray the nylon insulation layer in the tank. The insulation coating is very meaningful for the vehicle users in the north, and the vehicle users in the south can Without thermal insulation coating; of course, the method of external thermal insulation coating can also be used, for example, spray thermal insulation coating on the outside of the tank, or directly use thermal insulation to insulate; the upper part of the cylinder is connected by a flange, and the corresponding parts Pre-assembled on the flange cover; the inner wall of the barrel is thermally sprayed with nylon powder once; take a piece of 50ppi nickel-based metal foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com