Method for determining content of ferrous tartrate

A technology of ferrous tartrate and a determination method, applied in the direction of color/spectral property measurement and the like, can solve the problem that the method cannot be used to measure the complexing ability of meso ferrous tartrate, the content of meso ferrous tartrate cannot be accurately determined, Great influence and other problems, to achieve the effect of simple and feasible method, improved anti-caking effect, and improved complexation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: wavelength selection experiment

[0030] The present embodiment selects 240-370nm to test, and in this wavelength range, the absorbance of tartaric acid is almost negligible, but the absorbance of ferrous chloride decreases gradually, but still cannot be ignored; then select 410-570nm, in this In the wavelength range, the absorbance of tartaric acid at 410nm is 0.002, and its absorbance is almost zero after the wavelength increases. The absorbance of tartaric acid and ferrous chloride is almost negligible, but the absorbance of ferrous tartrate decreases gradually. Therefore, at 410nm, the absorbance of ferrous tartrate is the maximum, and the test results are shown in Table 1,

[0031] Table 1 Absorbance of different substances at different wavelengths

Embodiment 2

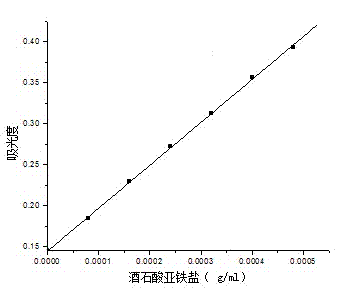

[0033] Determination of content of meso ferrous tartrate

[0034] Weigh 0.6g of the tartaric acid mixture, adjust the pH value to 6, and then transfer it into a three-neck flask, weigh 0.4g of ferrous chloride and dissolve it with double-distilled water, and transfer it into the dropping funnel after making a solution; turn on the constant temperature water bath and stirrer, Add ferrous chloride dropwise at 460°C. After the dropwise addition, react at a constant temperature for 0.5 hours and then cool naturally; transfer to a 500ml volumetric flask to constant volume. Take 10ml and add it to a 25ml colorimetric tube to make up the volume, measure its absorbance with a UV spectrophotometer, and measure it in parallel three times. regression equation,

[0035] Y=0.14547+522.13893X, where Y=0.345

[0036] The calculated X=3.82*10-4, and then converted to get the concentration of ferrous tartrate in the solution: 0.2682.

Embodiment 3

[0038] Complexation Ability Experiment of Different Configurations of Tartaric Acid and Ferrous Chloride

[0039] Weigh excess meso-tartaric acid, d-tartaric acid, and L-tartaric acid respectively, adjust the pH to 7, and react with 0.4 g of ferrous chloride at a temperature of 60°C. After the reaction is complete, the obtained solution will Under the same conditions, the absorbance was measured, and the results were 0.322, 0.332 and 0.326, respectively, indicating that the three configurations of tartaric acid had the same complexing ability as ferrous chloride under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com