Preparation method for ethyl urethane detection test paper and detection method of test paper

A technology of urethane and test paper, which is applied in the direction of biological testing, material inspection products, etc., can solve the problems that the accuracy cannot be compared with that of GC-MS, there are many impurities such as pigments, and cumbersome pretreatment steps, etc., and the detection method is simple. Rapid, simplified detection procedures, and small volume of test paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with implementation example the present invention is described in further detail:

[0030] The preparation method of this urethane test paper is carried out as follows:

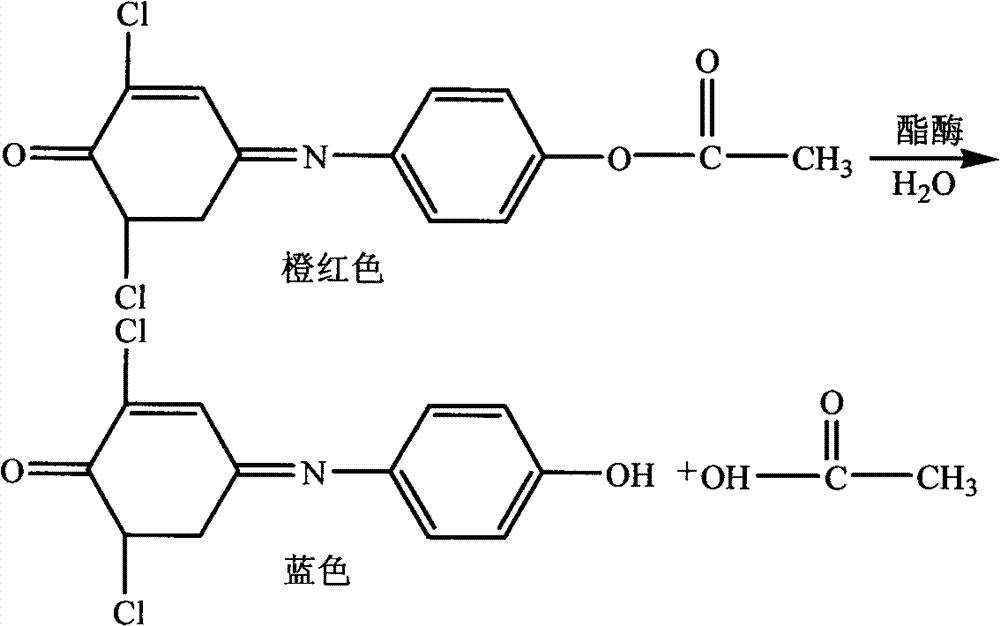

[0031] (1) Material preparation: acetylcholinesterase with activity ≥ 220u / g, ethyl carbamate with a purity of 99%, the paper base of the test paper is a medium-speed qualitative filter paper with good water absorption, and the substrate is 1g L -1 2,6-dichloroindophenol acetate;

[0032] (2) Preparation of enzyme solution: 10 u of acetylcholinesterase, 2 μL of glutaraldehyde with a volume ratio of 5%, and 10 μL of BSA with a mass ratio of 1%, were prepared into a 70 μL enzyme solution;

[0033] (3) Preparation of test paper: the above-mentioned enzyme solution and qualitative filter paper were routinely immobilized at 3° C. for 8 hours to obtain urethane detection test paper.

[0034] The method that this urethane test paper detects is carried out as follows:

[0035] (1) Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com