Porous multi-layer film with improved thermal properties

A multi-layer film and porous film technology, applied in the direction of layered products, household appliances, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

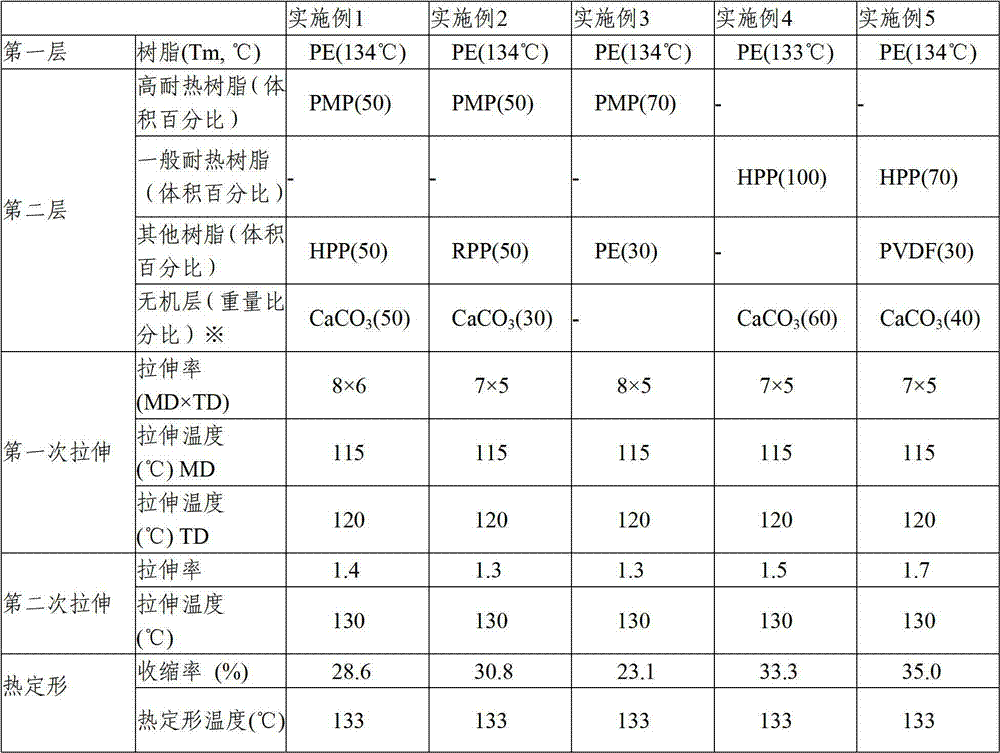

Embodiment 1

[0127] In the first layer, use 3.0×10 5 Polyethylene with a weight-average molecular weight and a melting temperature of 134°C and a paraffin oil with a dynamic viscosity of 95cSt at 40°C. The weight percentages of these two components are 30% and 70% respectively. In the second layer, polymethylpentene with a melting index of 9.0 (260°C, 5Kg) and a volume percentage of 50% is used as a high heat-resistant resin, and it has a 5.7×10 5 Polypropylene with a weight-average molecular weight and a melting temperature of 163°C and a volume percentage of 50% is used as another resin separated from the liquid-liquid state of the high heat-resistant resin. CaCO with an average particle size of 1.5μm and a weight percentage of 50% 3 Used as an inorganic material.

[0128] After co-extrusion of the first layer formed on both surfaces of the three layers, the sheet was stretched 8 times at 115°C in the longitudinal direction (MD) and 120°C in the transverse direction (TD) The bottom is stre...

Embodiment 2

[0130] In the first layer, use 3.0×10 5 Polyethylene with a weight-average molecular weight and a melting temperature of 134°C and a paraffin oil with a dynamic viscosity of 95cSt at 40°C. The weight percentages of these two components are 30% and 70% respectively. In the second layer, polymethylpentene with a melting index of 9.0 (260°C, 5Kg) and a volume percentage of 50% is used as a high heat-resistant resin, and a 2.5×10 5 Polypropylene with a weight-average molecular weight and a melting temperature of 148°C and a volume percentage of 50% is used as another resin separated from the liquid-liquid state of the high heat-resistant resin. CaCO with an average particle size of 1.5μm and a weight percentage of 30% 3 Used as an inorganic material.

[0131] After co-extrusion of the first layer formed on both surfaces of the three layers, the sheet was stretched 7 times at 115°C in the longitudinal direction (MD) and at 120°C in the transverse direction (TD) The bottom is stretche...

Embodiment 3

[0133] In the first layer, use 3.0×10 5 Polyethylene with a weight-average molecular weight and a melting temperature of 134°C and a paraffin oil with a dynamic viscosity of 95cSt at 40°C. The weight percentages of these two components are 30% and 70% respectively. In the second layer, polymethylpentene with a melting index of 9.0 (260°C, 5Kg) and a volume percentage of 70% is used as a high heat-resistant resin, and a 2.3×10 5 Polyethylene with a weight-average molecular weight and a melting temperature of 133°C and a volume percentage of 30% is used as another resin separated from the liquid-liquid state of the high heat-resistant resin.

[0134] After co-extrusion of the first layer formed on both surfaces of the three layers, the sheet was stretched 8 times at 115°C in the longitudinal direction (MD) and 120°C in the transverse direction (TD) The bottom is stretched 5 times. The diluent was extracted with dichloromethane by liquid immersion method, and the extraction time wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com