Method for preparation of natural cheese essence with whey powder

A technology of natural cheese and whey powder, which is applied in food preparation, application, food science, etc., can solve the problems of high production cost and utilization of whey powder, and achieve the effect of improving nutritional value and flavor, low cost, and round and full aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

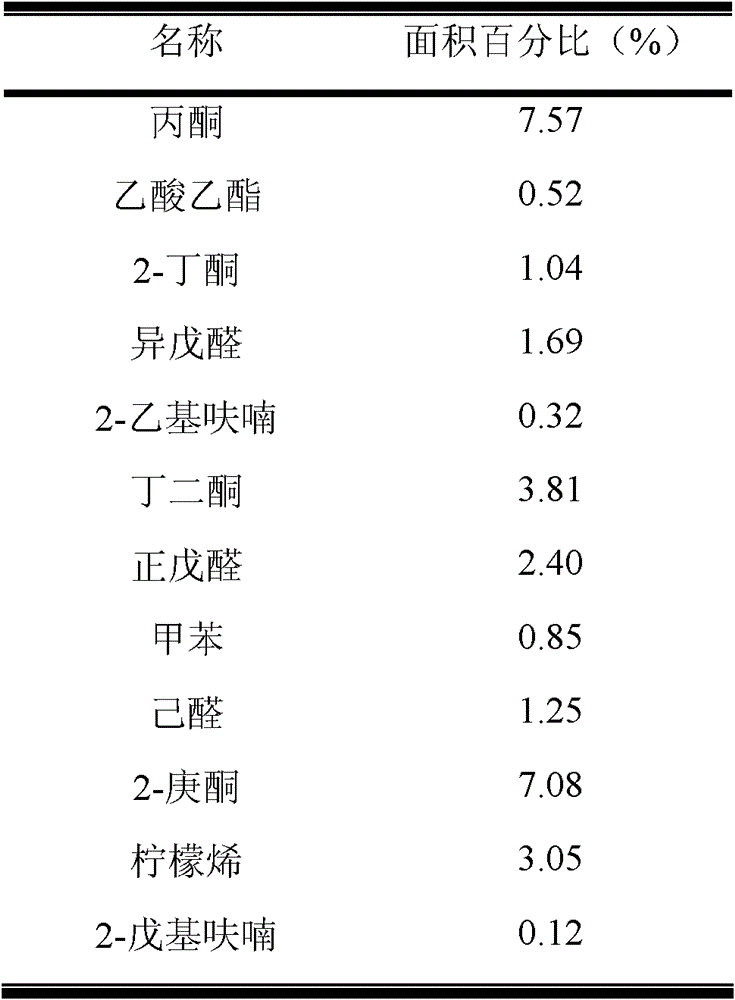

Image

Examples

Embodiment 1

[0025] (1) Preparation and sterilization of the solution: mix whey powder and whole milk powder in a ratio of 1:2, dissolve and prepare a liquid with a mass fraction of 12%, and add 0.5% sodium citrate at the same time to dissolve The solution was sterilized at 105°C for 10 minutes.

[0026] (2) Inoculation and fermentation: Mix Danisco's Choozit MD88 Lactococcus lactis and Chr-Hansen LH-B02 Lactobacillus helveticus in a ratio of 1:1, then add it to the solution prepared in the above step (1), the inoculation amount is the mass The fraction is 0.024%, mixed evenly after inoculation, fermented continuously in a fermenter at 38°C and 150r / min for 30h, and sterilized at 80°C for 20min.

[0027] (3) Enzymolysis: Add Valley lipase and flavor enzyme to the solution prepared in the above step (2) according to the addition amount of 0.06% of the solution mass, mix well, and react in a reaction tank at 40°C and 150r / min Medium enzymatic hydrolysis for 5 hours, enzyme inactivation at 8...

Embodiment 2

[0029] The same as Example 1, the difference is that the amount of whey powder is increased in step (1), and the whey powder and whole milk powder are evenly mixed in a ratio of 1:1, dissolved and shaken to prepare a mass fraction of 12 % liquid medium. Increasing the proportion of whey powder in the substrate ratio can achieve the same effect while reducing production costs.

Embodiment 3

[0031] Same as Example two, the difference is: the fermentation time has been reduced in step (2), and the type of bacteria has been changed simultaneously. After mixing the Lactococcus lactis 11166 of the American ATCC strain bank and Danisco's Choozit LH100 Lactobacillus helveticus according to the ratio of 1:1, add it to the solution prepared in step (1), the inoculum amount is 0.024% by mass fraction, after inoculation Mix evenly, ferment continuously in a fermenter at 38°C and 150r / min for 25h, and sterilize at 80°C for 20min. Changing the type of bacteria and reducing the fermentation time can achieve the same effect, while reducing production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com