Crossed pore aerator with protecting film

A protective film and cross-hole technology, applied in water aeration, chemical instruments and methods, flotation water/sewage treatment, etc., can solve problems such as clogging of aeration holes, affecting aeration effect, affecting water treatment quality, etc., to achieve Save operating costs, expand the pressure range, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

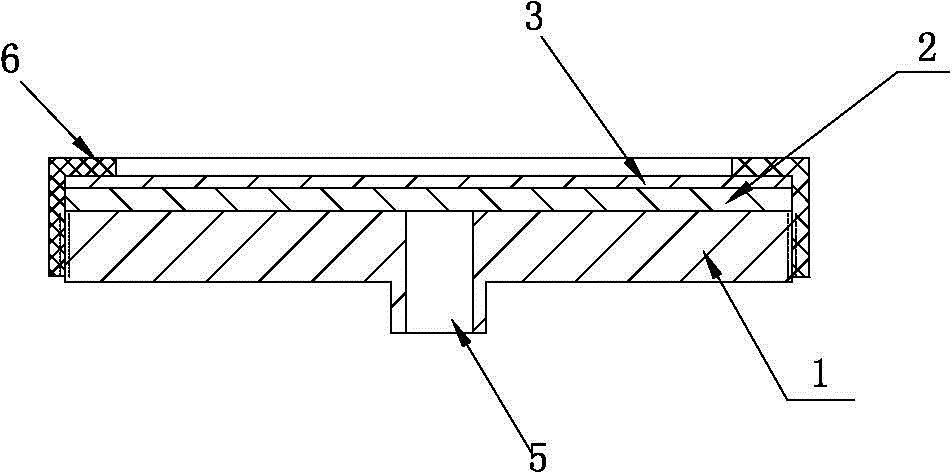

[0026] Such as figure 1 , 4 shown.

[0027] A cross-hole aerator with a protective film, comprising a circular flat plate substrate 1 and a diaphragm 2, the diaphragm 2 is provided with a protective film layer 3 integrally connected with it, and the diaphragm 2 is One of EPDM, silica gel, fluorine rubber or nitrile rubber diaphragm, the protective film layer 3 is a polymer material coating (its main components are: polytetrafluoroethylene, polyurethane, can also be directly obtained from Market procurement, the same below), the protective film layer 3 can also adopt the anti-bath coating coated on the surface of the existing marine ship, the center of the circular flat substrate 1 is provided with an air inlet 5, the The diaphragm 2 is press-fitted on the base plate 1 through the pressure ring 6, and the pressure ring 6 is connected with the base plate 1 through threads, such as figure 1 As shown, the periphery of the diaphragm 2 is sealed and connected with the periphery o...

Embodiment 2

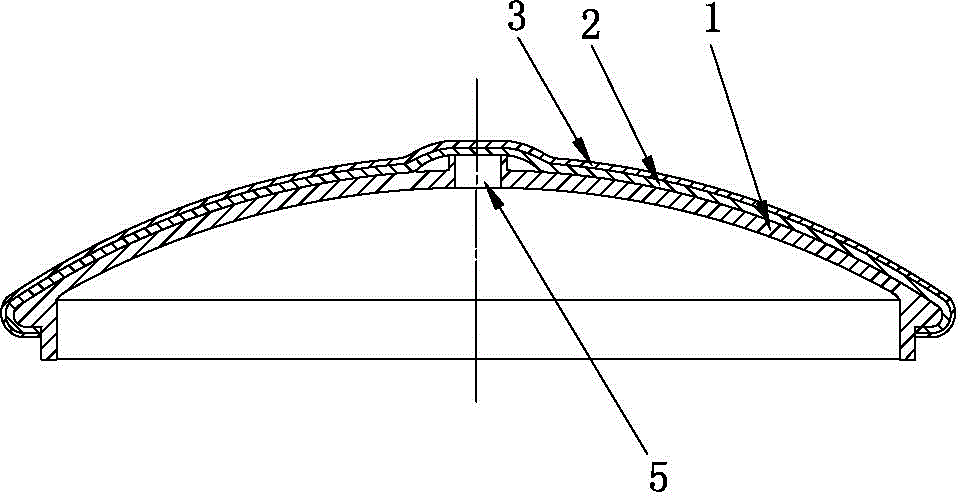

[0029] Such as figure 2 , 4 shown.

[0030] A cross-hole aerator with a protective film, comprising a spherical crown substrate 1 and a spherical crown diaphragm 2, the diaphragm 2 is provided with a protective film layer 3 integrally connected with it, the diaphragm 2 It is one of EPDM, silica gel, fluorine rubber or nitrile rubber diaphragm, and the protective film layer 3 is a polymer material coating (its main components are: polytetrafluoroethylene, polyurethane). The protective film layer 3 also can adopt the anti-bath coating that the surface of the existing marine ship is coated with, the center of the described spherical structure substrate 1 is provided with an air inlet 5, and the protective film layer 3 is coated together with the diaphragm 2 On the spherical cap base plate 1, and rely on its elastic force to fit tightly on the spherical cap structure, such as figure 2 As shown, the diaphragm 2 is fastened around the lower part of the substrate 1 to form a sea...

Embodiment 3

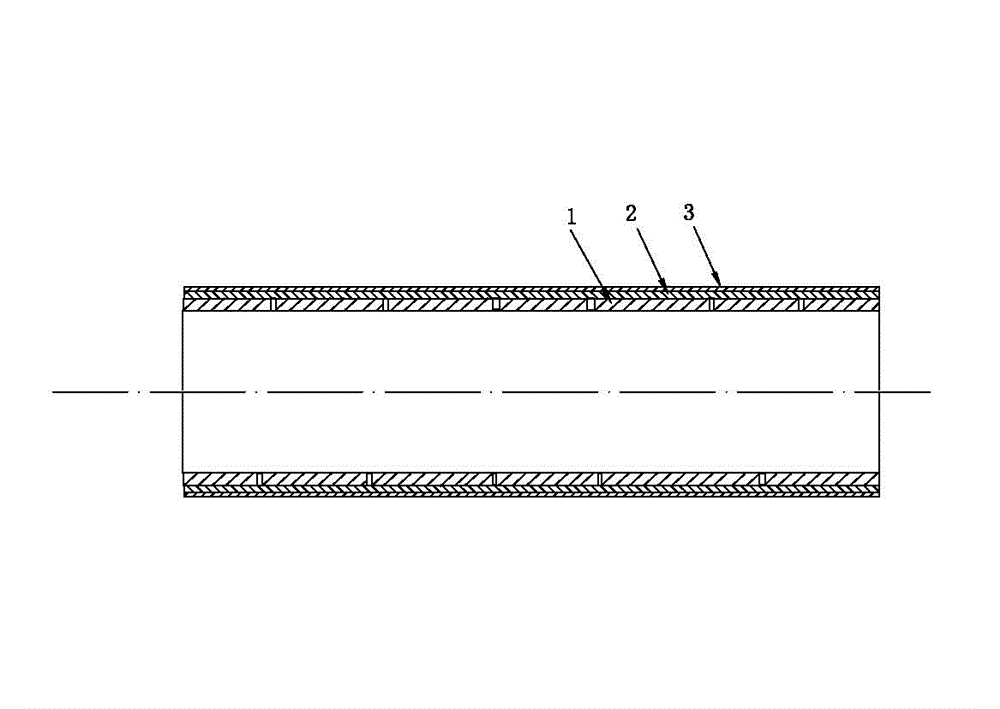

[0032] Such as image 3 , 5 shown.

[0033] A cross-hole aerator with a protective film, including a pipe body 1 and a tubular diaphragm 2, the diaphragm 2 is provided with a protective film layer 3 integrally connected with it, and the diaphragm 2 is a three-dimensional One of ethylene propylene, silica gel, fluorine rubber or NBR diaphragm, the protective film layer 3 is a polymer material coating (its main components are: polytetrafluoroethylene, polyurethane), the protective film layer 3. The anti-bath coating applied on the surface of the existing marine ships can also be used. The pipe wall of the pipe body 1 is provided with a radial through hole communicating with the pipe core, and the protective film layer 3 is set together with the diaphragm 2. on tube body 1, such as image 3 As shown, the two ends of the diaphragm 2 are fixed on the pipe body 1 by fastening rings. In the same way, when the pressure in the air chamber is greater than the opening pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com