Crystallizing method of solid antioxidant

An antioxidant and crystallization technology, applied in the field of crystallization of solid antioxidants, can solve the problems of low concentration of antioxidants, difficult polymer particles, and uniform mixing, so as to improve product purity, control the number of crystal nuclei, and achieve uniform crystallization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

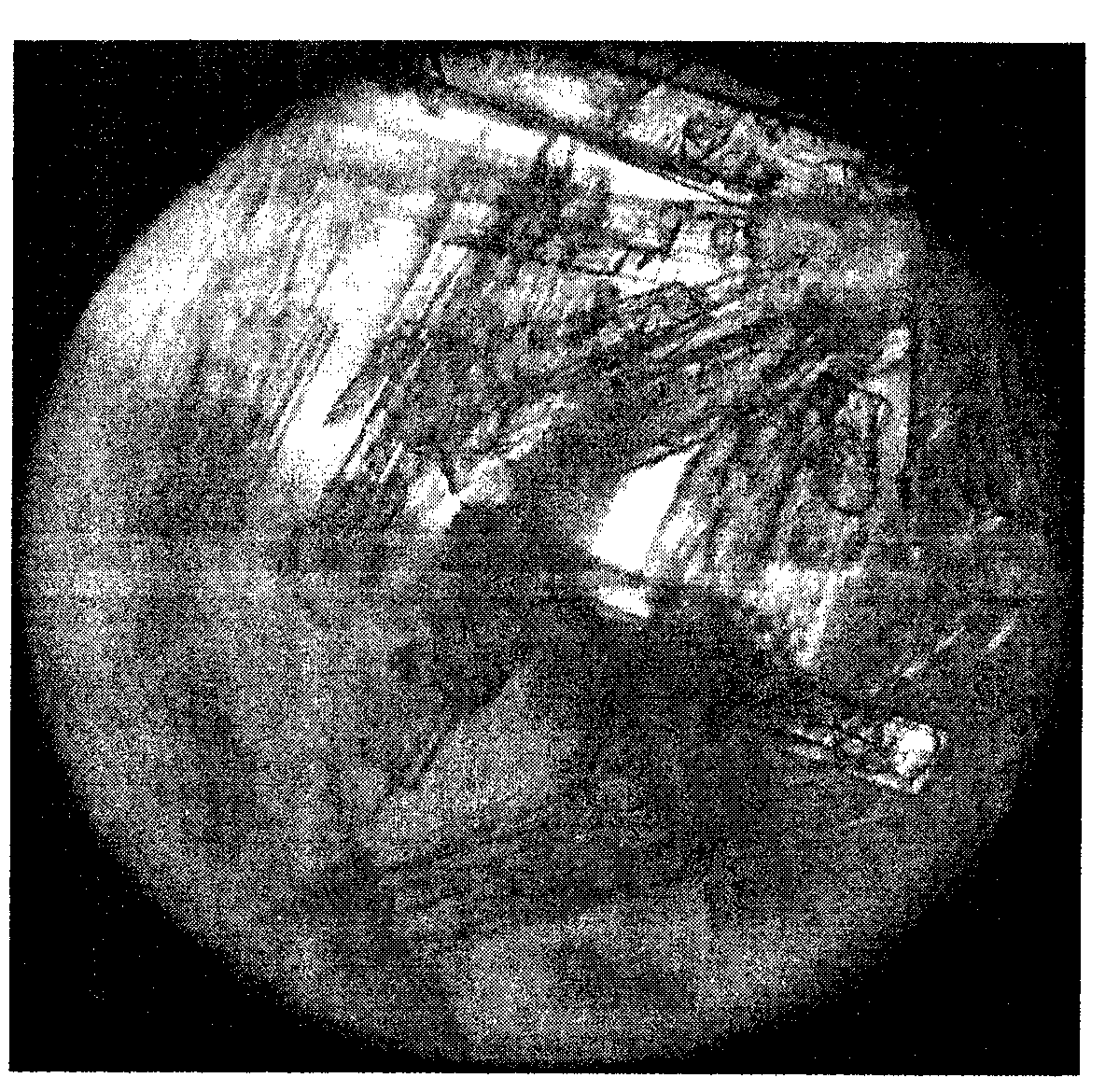

Embodiment 1

[0023] In a 500ml three-necked flask equipped with electric stirring, thermometer, vacuum control device, condenser, and cold trap, 60g (0.205mol) of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid methyl ester (3 , 5-methyl ester), 55 g (0.203 mol) octadecyl alcohol, 0.1 g of dibutyl tin oxide, adjust the vacuum to 50-100mmHg, heat up to 100-120°C, keep stirring, and keep the methanol generated during the reaction Aspirate and collect in a cold trap, keep the reaction under these conditions for about 2 hours, and then raise the temperature to 125-135°C, continuously extract the methanol generated during the reaction, and collect in the cold trap, and keep the reaction under these conditions for about 1 hour , Evacuate until the vacuum degree is less than 2mmHg to complete the reaction. Cool down to 60-70℃, add 300ml (239.28g) of methanol into the reaction flask, keep stirring, heat to boiling, dissolve for about 10 minutes to obtain a colorless and transparent mixed liquid, ke...

Embodiment 2

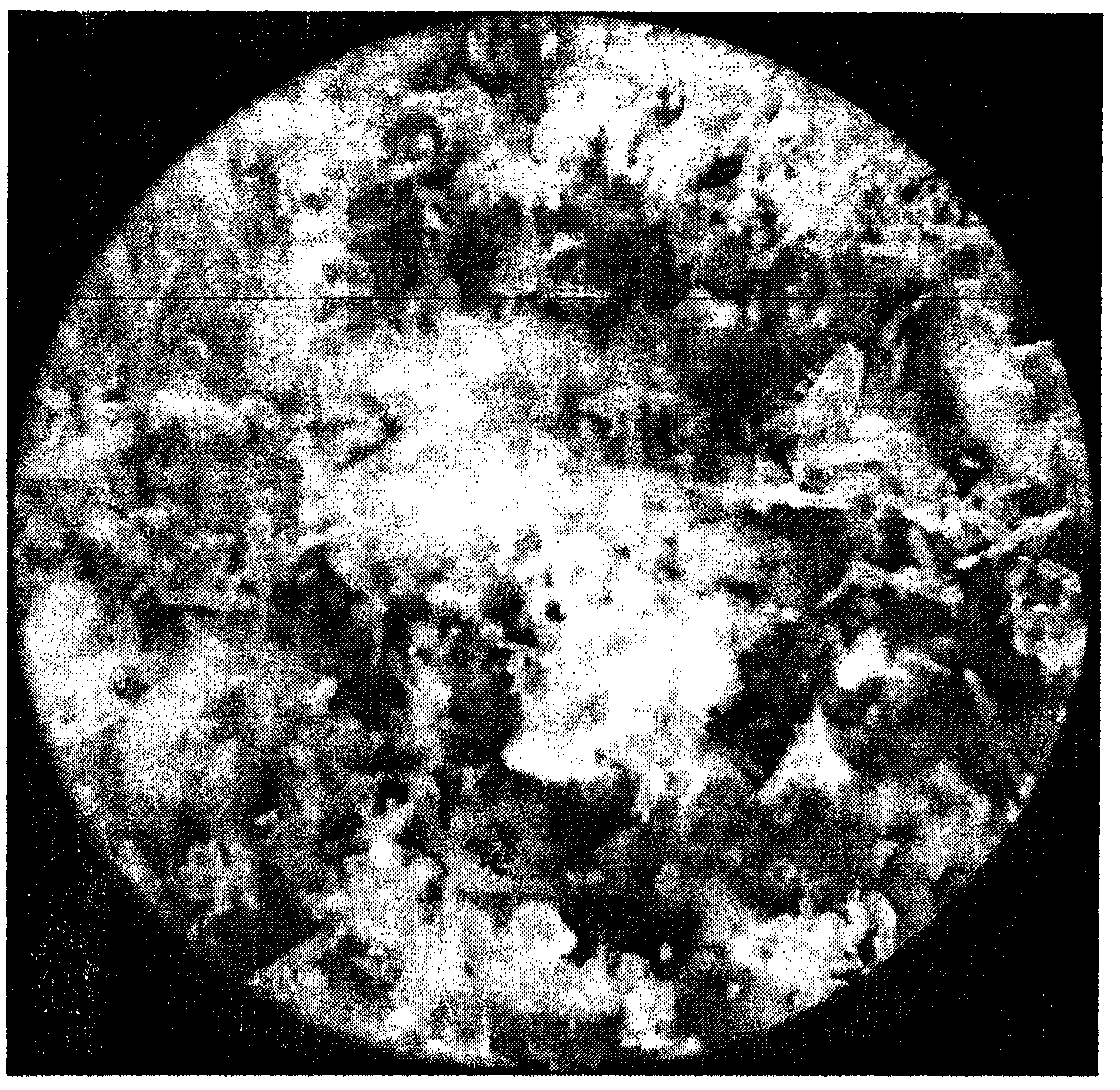

[0025] In a 500ml three-necked flask equipped with electric stirring, thermometer, vacuum control device, condenser, and cold trap, 60g (0.205mol) of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid methyl ester (3 , 5-methyl ester), 55 g (0.203 mol) octadecyl alcohol, 0.1 g of dibutyl tin oxide, adjust the vacuum to 50-100mmHg, heat up to 100-120°C, keep stirring, and keep the methanol generated during the reaction Aspirate and collect in a cold trap, keep the reaction under these conditions for about 2 hours, and then raise the temperature to 125-135°C, continuously extract the methanol generated during the reaction, and collect in the cold trap, and keep the reaction under these conditions for about 1 hour , To the vacuum degree less than 2mmHg or less to end the reaction. Cool down to 60-70°C, add 400ml (322.48g) of ethanol to the reaction flask, keep stirring, heat to boiling, dissolve for about 5 minutes to obtain a colorless and transparent mixed liquid, keep stirring, th...

Embodiment 3

[0027] In a 500ml three-necked flask equipped with electric stirring, thermometer, vacuum control device, condenser, and cold trap, 60g (0.205mol) of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid methyl ester (3 , 5-methyl ester), 55 g (0.203 mol) octadecyl alcohol, 0.1 g of dibutyl tin oxide, adjust the vacuum to 50-100mmHg, heat up to 100-120°C, keep stirring, and keep the methanol generated during the reaction Aspirate and collect in a cold trap, keep the reaction under these conditions for about 2 hours, and then raise the temperature to 125-135°C, continuously extract the methanol generated during the reaction, and collect in the cold trap, and keep the reaction under these conditions for about 1 hour , To the vacuum degree less than 2mmHg or less to end the reaction. Cool down to 60-70°C, add 150ml (117.77g) of isopropanol to the reaction flask, keep stirring, heat to boiling, dissolve for about 20 minutes to obtain a colorless and transparent mixed liquid, keep stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com