Method for extracting chrysalis oil

A technology of silkworm chrysalis oil and extraction, which is applied in the direction of fat oil/fat production and fat production, so as to improve the immune function of the human body, easy to operate, and delay the aging of human body functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

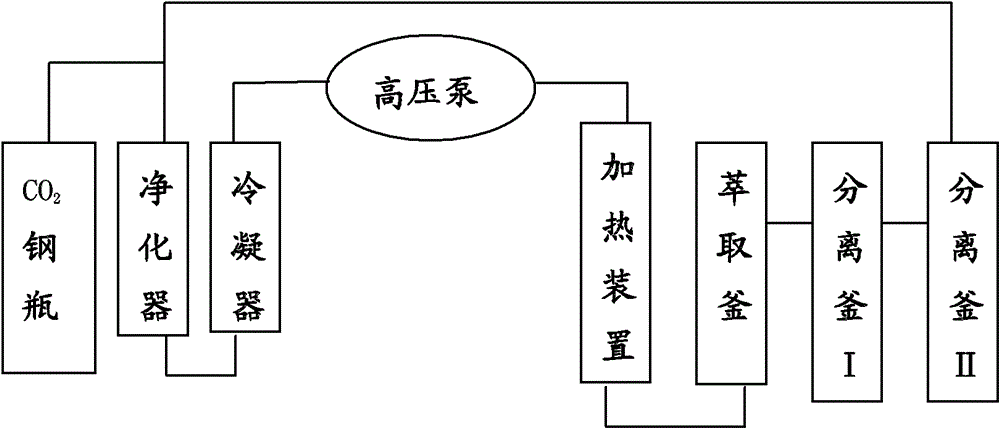

[0061] Embodiment 1 Supercritical fluid extraction method of the present invention extracts silkworm chrysalis oil

[0062] Accurately weigh 1051.2g of wet silkworm chrysalis, put it into a blower at 70°C to dry for 48 hours, put it in a pulverizer after sterilization, pass through a 40-mesh sieve, and set aside.

[0063] Turn on the power of the supercritical fluid extraction device, turn on the refrigeration and cold cycle, adjust the temperature of the temperature control device of the extraction kettle to 55°C, adjust the temperature of the temperature control device of the separation kettle I to 50°C, and adjust the temperature control device of the separation kettle II to 35°C . Put the crushed and sieved silkworm chrysalis into the barrel, put them into the extraction kettle, install the sealing ring, and tighten the plug. After the temperature of the extraction kettle, separation kettle I, and separation kettle II reaches the set temperature, turn on the CO 2 Steel c...

Embodiment 2

[0064] Embodiment 2 Supercritical fluid extraction method of the present invention extracts silkworm chrysalis oil

[0065] Accurately weigh 1060.0g of wet silkworm chrysalis, put it into a blower at 70°C to dry for 48 hours, put it in a pulverizer after sterilization, pass it through a 40-mesh sieve, and set aside.

[0066] Turn on the power of the supercritical fluid extraction device, turn on the refrigeration and cold cycle, adjust the temperature of the temperature control device of the extraction kettle to 55°C, adjust the temperature of the temperature control device of the separation kettle I to 46°C, and adjust the temperature control device of the separation kettle II to 41°C . Put the crushed and sieved silkworm chrysalis into the barrel, put them into the extraction kettle, install the sealing ring, and tighten the plug. After the temperature of the extraction kettle, separation kettle I, and separation kettle II reaches the set temperature, turn on the CO 2 Stee...

Embodiment 3

[0067] Embodiment 3 Supercritical fluid extraction method of the present invention extracts silkworm chrysalis oil

[0068] Accurately weigh 1050.0g of wet silkworm chrysalis, put it into a blower at 70°C to dry for 48 hours, put it in a pulverizer after sterilization, pass through a 40-mesh sieve, and set aside.

[0069] Turn on the power of the supercritical fluid extraction device, turn on the refrigeration and cold cycle, adjust the temperature of the temperature control device of the extraction kettle to 55°C, adjust the temperature of the temperature control device of the separation kettle I to 65°C, and adjust the temperature control device of the separation kettle II to 55°C . Put the crushed and sieved silkworm chrysalis into the barrel, put them into the extraction kettle, install the sealing ring, and tighten the plug. After the temperature of the extraction kettle, separation kettle I, and separation kettle II reaches the set temperature, turn on the CO 2 Steel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com