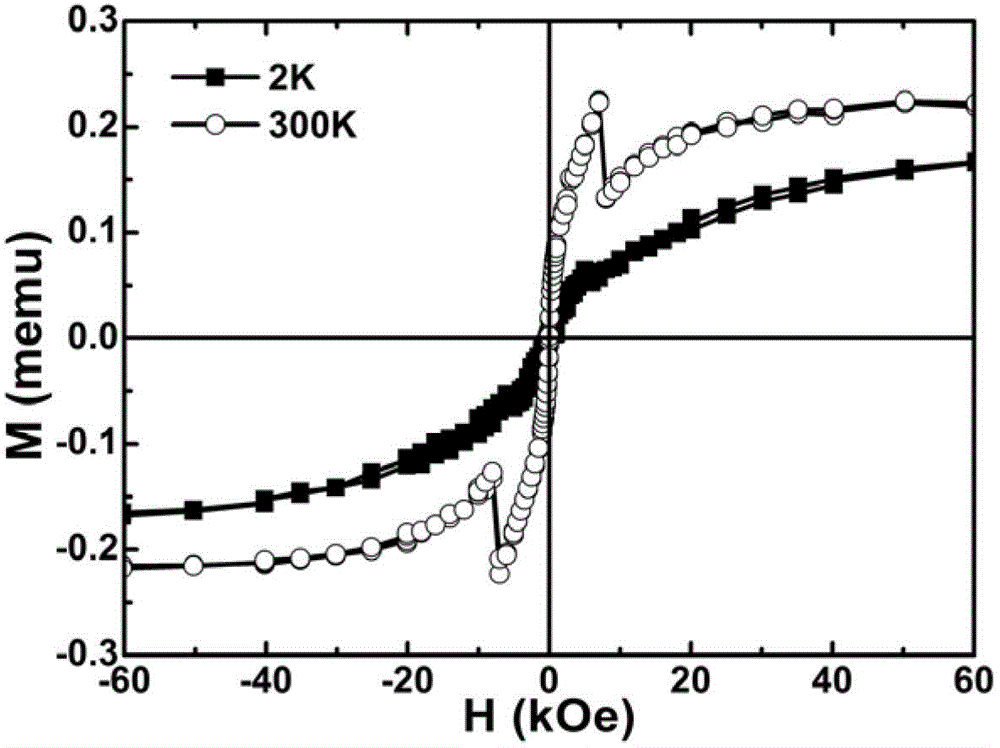

Undoped room-temperature ferromagnetic spinning zero-gap semiconductor film and preparation method thereof

A room temperature ferromagnetic and semiconductor technology, applied in solid-state chemical plating, metal material coating process, coating and other directions, can solve the problem of not finding the related characteristics of spin zero band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

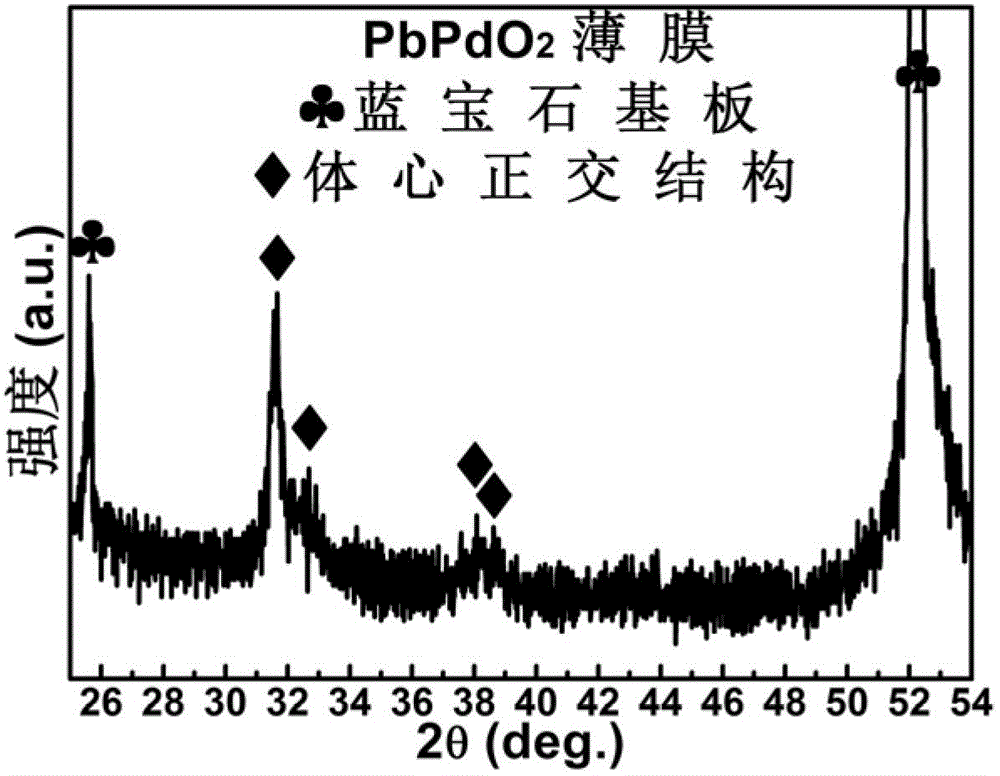

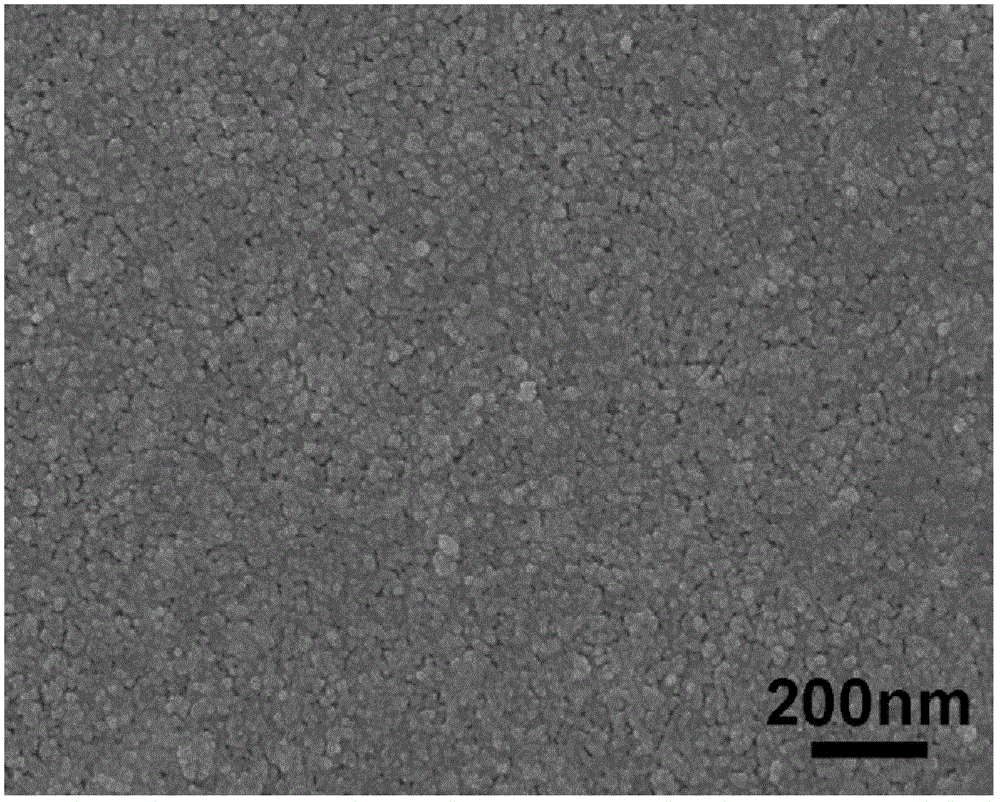

Embodiment 1

[0025] Measure 50ml ethylene glycol as organic solvent, according to the final product PbPdO 2 To a concentration of 0.3mol / L, weigh lead nitrate (AR) and palladium nitrate (AR) respectively, and dissolve them completely in ethylene glycol respectively, then mix the two solutions and dilute them with ethylene glycol, wherein, The atomic ratio of lead and palladium is set to 1.02:1, and the excess of Pb by 2at.% is to make up for the loss of lead in the subsequent heat treatment process;

[0026] Weigh citric acid according to the molar number of 2.2×0.3mol / L×50ml×(1.02+1), add it to the above mixed solution, place it in an environment of 64°C, and stir for 6 hours to obtain a completely complexed sol;

[0027] Coating the sol on the sapphire single crystal substrate to form a film by using the spin-coating process. The process parameters of the first step are: 700rpm×12 seconds; the parameters of the second step are: 3000rpm×30 seconds;

[0028] Place the film in an oven and ...

Embodiment 2

[0039] Get 50ml ethylene glycol as organic solvent, according to final product PbPdO 2 The concentration is 0.08mol / L, weigh lead chloride (AR) and palladium chloride (AR) respectively, and dissolve them completely in ethylene glycol respectively, then mix the two solutions and dilute them with ethylene glycol, Among them, the atomic ratio of lead and palladium is set to 1.05:1, and the excess of Pb by 5at.% is to compensate for the loss of lead in the subsequent heat treatment process;

[0040] Weigh citric acid according to the molar number of 2.2×0.08mol / L×50ml×(1.05+1), add it to the above mixed solution, place it in an environment of 68°C, and stir for 6 hours to obtain a completely complexed sol;

[0041] Using the spin-coating process, the sol is coated on the sapphire single crystal substrate to form a film. The process parameters of the first step are: 800rpm×10 seconds; the process parameters of the second step are: 3500rpm×40 seconds;

[0042] Place the film in an ...

Embodiment 3

[0051] Measure 50ml ethylene glycol as organic solvent, according to the final product PbPdO 2 The concentration is 0.2mol / L, weigh lead nitrate (AR) and palladium chloride (AR) respectively, and dissolve them completely in ethylene glycol respectively, then mix the two solutions and dilute them with ethylene glycol, where , the atomic ratio of lead and palladium is set to 1.1:1, and the excess of Pb by 10at.% is to make up for the loss of lead in the subsequent heat treatment process;

[0052] Weigh citric acid according to the molar number of 2.2×0.2mol / L×50ml×(1.1+1), add it to the above mixed solution, place it in an environment of 70°C, and stir for 6 hours to obtain a completely complexed sol;

[0053] Coating the sol on the sapphire single crystal substrate to form a film by using the spin-coating process. The process parameters of the first step are: 600rpm×15 seconds; the parameters of the second step are: 4000rpm×20 seconds;

[0054] Place the film in an oven and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com