Automatic measuring station for water surface evaporation capacity

An automatic measurement and water surface evaporation technology, applied in the direction of instruments, etc., can solve the problems of the increase of the total error of the water surface evaporation system, the difficulty of popularization, and the increase of measurement overflow, etc., to achieve a simple calibration method, easy to popularize and use, and a system The effect of measurement error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

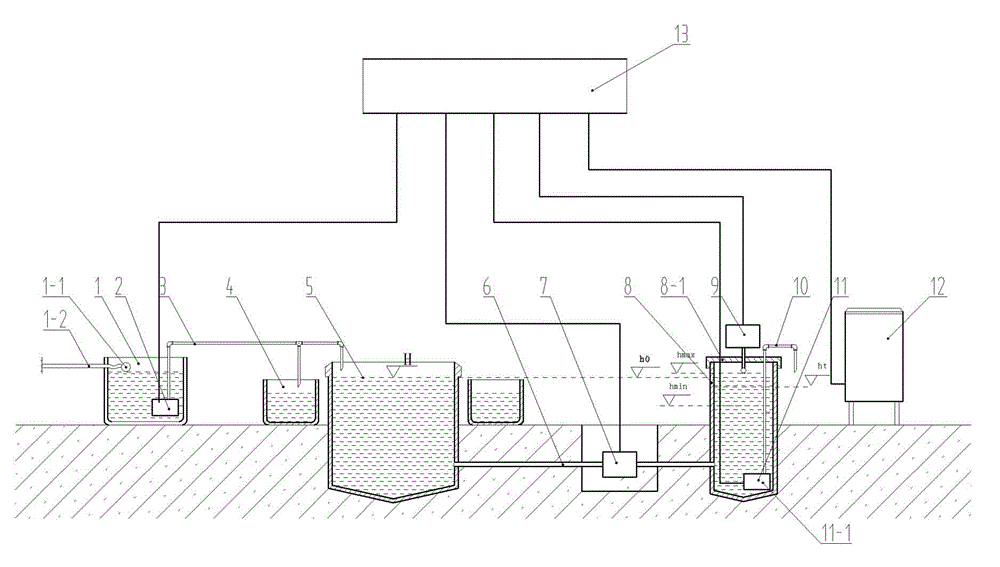

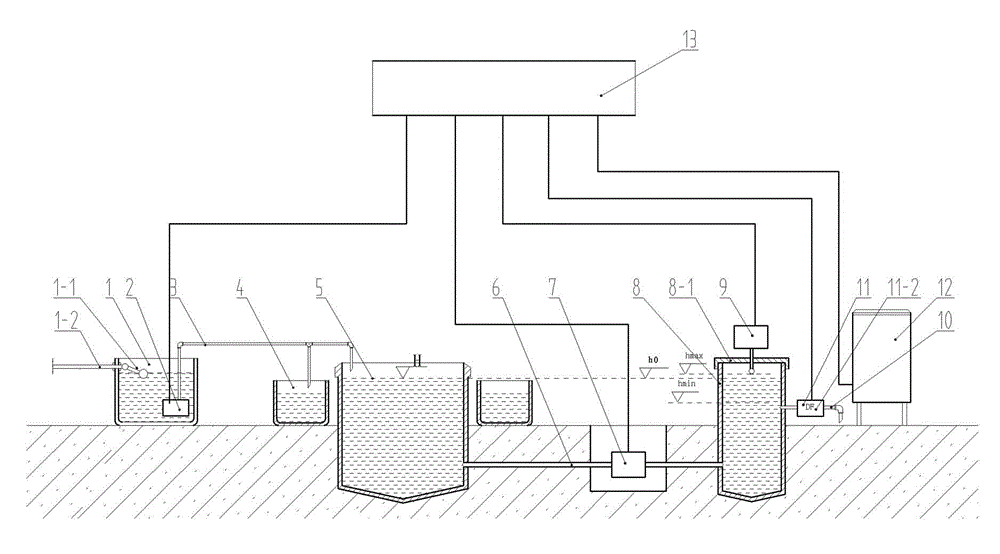

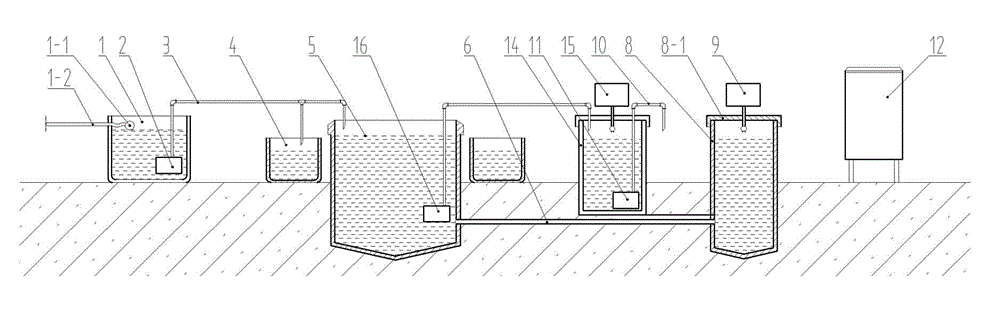

[0020] Such as figure 1 , figure 2 , image 3 Shown is: an automatic measuring station for water surface evaporation, which includes: evaporation barrel 5, hydrosphere 4, still water barrel 8, evaporation sensor 9, rain sensor 12, water replenishment barrel 1 and acquisition controller 13. There are many water rings 4, and many water rings 4 are evenly distributed around the evaporation bucket 5; the water replenishment bucket 1 is connected to the water level through the float type automatic water level control valve 1-1 and the water inlet pipe 1-2. Network connection, water replenishment pump 2 is installed in the water replenishment barrel 1, and described replenishment water pump 2 supplies water to the evaporation barrel 5 and the water circle 4 through the water delivery pipe 3 under the control of the acquisition controller 13. The rain sensor 12 is installed in the observation field, and its signal output terminal is connected with the acquisition controller 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com