Oriented structural board for container soleplate

A technology of oriented structural panels and container bottom plates, which is applied in the jointing of wooden veneers, wood processing appliances, and layered products, etc. and other issues, to reduce the damage to forests and the environment, save space, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

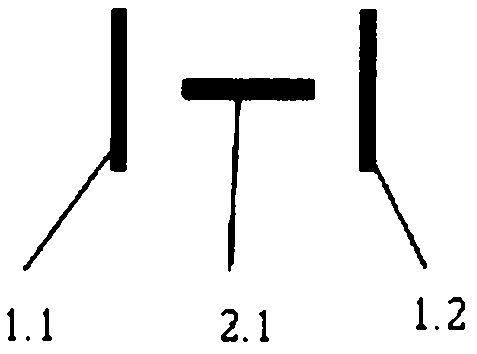

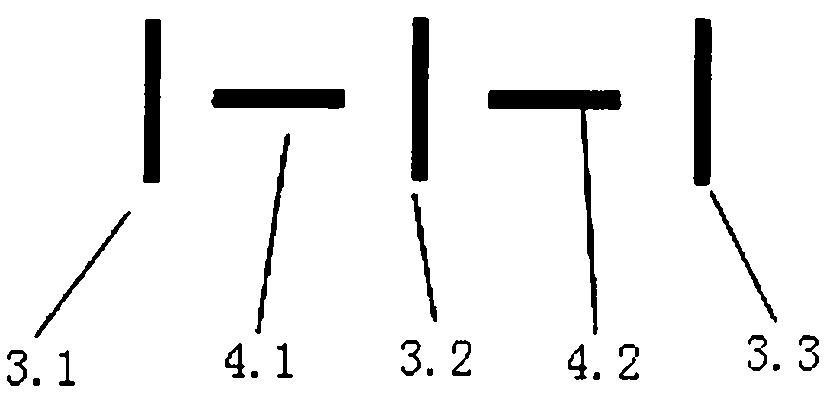

[0029] Peel and flake the poplar. The length of the flakes is 180mm, the thickness is 0.6mm, and the average width is 20mm. The flakes are dried at 150°C. After drying, the moisture content of the flakes is not higher than 6%. Glue, the adhesive is PMDI isocyanate, and insect repellant is added during the sizing process, and the insect repellent is Radaluem FHP-60. Using three-layer directional paving process, see figure 1 , the uppermost layer 1.1 and the lowermost layer 1.2 are longitudinal pavement layers, the core layer 2.1 is a horizontal pavement layer, and the mass ratio of the uppermost layer-core layer-lowermost layer is 27.5: 45: 27.5, pre-spray steaming after paving, and then Carry out high-tonnage continuous hot-press forming, the surface pressure of the continuous press is 2.0Mpa, and balance the internal stress after hot-pressing, that is to say. The density of the product is 0.81g / cm 3 , the thickness is 12mm, the water content is 4.8%, the longitudinal static...

Embodiment 2

[0031] Peel and flake poplar wood and its branches. The length of the flakes is 160mm, the thickness is 0.8mm, and the average width is 35mm. The flakes are dried at 170°C. After drying, the moisture content of the flakes is not higher than 6%. Sheets, and then sizing, the glue is melamine urea-formaldehyde resin, insect repellant is added during the sizing process, and the insect repellent is Meganium2000. Using three-layer directional paving process, see figure 1, the uppermost layer 1.1 and the lowermost layer 1.2 are longitudinal pavement layers, the core layer 2.1 is a horizontal pavement layer, the mass ratio of the uppermost layer-core layer-lowermost layer is 32.5: 35: 32.5, pre-spraying is carried out after paving, and then Carry out high-tonnage continuous hot-press forming, the surface pressure of the continuous press is 3.1Mpa, and balance the internal stress after hot-pressing. The density of the product is 0.80g / cm 3 , the thickness is 14mm, the water content i...

Embodiment 3

[0033] Peel and flake poplar wood and its branches. The length of the flakes is 200mm, the thickness is 0.7mm, and the average width is 30mm. The flakes are dried at 160°C. After drying, the moisture content of the flakes is not higher than 6%. Sheets, and then sizing, the glue is urea-formaldehyde resin, and insect repellent is added during the sizing process, and the insect repellent is Meganium3000. Using three-layer directional paving process, see figure 1 , the uppermost layer 1.1 and the lowermost layer 1.2 are longitudinal pavement layers, the core layer 2.1 is a horizontal pavement layer, the mass ratio of the uppermost layer-core layer-lowermost layer is 30:40:30, pre-spray steaming after paving, and then Carry out high-tonnage continuous hot-press forming, the surface pressure of the continuous press is 3.4Mpa, and balance the internal stress after hot-pressing is balanced, that is to say. The density of the product is 0.85g / cm 3 , the thickness is 30mm, the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com