Ultraviolet ray separating greenhouse film

A UV blocking and ultraviolet technology, applied in greenhouse cultivation, synthetic resin layered products, horticulture, etc., can solve the problems of not being able to prevent flower black spot and not being able to suppress ultraviolet light, so as to delay the mutual transmission of viruses and control black spots Disease, the effect of enhancing commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

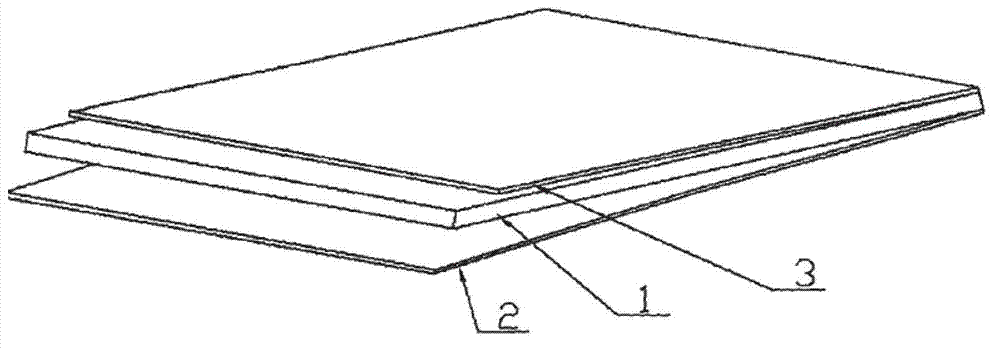

[0029] The preparation method of the anti-ultraviolet blocking greenhouse film is as follows: the relevant raw materials of the inner layer 2, the middle layer 1, and the outer layer 3 are put into the warehouse and automatically batched, wherein the ultraviolet inhibitor is an ultraviolet inhibitor using LDPE or LLDPE as a carrier. It is added in the form of masterbatch, and the mass ratio of UV inhibitor in LDPE or LLDPE is 15-25%; it is weighed and sent to the screw of the three-layer co-extrusion blown film equipment to mix and extrude and plasticize into a melt; filter and filter , diverted to the die head through the flow channel, extruded and compounded to form a film; the extruded film is then blown, drawn, folded, and rolled to form the finished UV barrier film.

[0030] The ultraviolet blocking film products in the examples were prepared using a three-layer co-extrusion blown film equipment conventionally configured by Davis Corporation in the United States.

[0031]...

Embodiment 1

[0033] An ultraviolet blocking greenhouse film with a three-layer co-extruded composite film structure comprising an inner layer, a middle layer and an outer layer. Among them, the outer layer material is PE with 12% anti-aging agent and 2% slow-release agent, and the middle layer material is added with 5% ultraviolet inhibitor, 10% dripping anti-fogging agent, 5% heat preservation agent, and 12% anti-aging EVA with 4% slow-release agent and 4% slow-release agent, the inner layer is made of EVA and PE with 12% anti-aging agent, 2% slow-release agent and 10% dripping anti-fogging agent. In the inner layer, the weight ratio of EVA and PE is 1:2.

[0034] Among them, the ultraviolet inhibitor is a masterbatch made of benzotriazole and benzophenone compounded and plasticized with LLDPE as the carrier, and the weight ratio of benzotriazole and benzophenone is 80:20; and the ultraviolet inhibitor is contained in LLDPE The mass ratio is 20%.

[0035] The thickness ratio of the oute...

Embodiment 2

[0038] An ultraviolet barrier film with a three-layer co-extruded composite film structure comprising an inner layer, a middle layer and an outer layer. Among them, the outer layer material is PE with 12% anti-aging agent and 2% slow-release agent, and the middle layer material is added with 10% dripping anti-fogging agent, 4% slow-release agent, 12% anti-aging agent, 7% ultraviolet light Inhibitor EVA and PE, the inner material is PE added with 10% dripping anti-fogging agent, 2% slow-release agent and 12% anti-aging agent. In the middle layer, EVA and PE are used in a weight ratio of 1:2.

[0039] Among them, the ultraviolet inhibitor is a masterbatch formed by compounding and plasticizing benzotriazole, benzophenone-3, and benzophenone using LDPE as the carrier, and the added weight of benzotriazole, benzophenone-3, and benzophenone The ratio is 60:20:20; and the mass ratio of ultraviolet inhibitor in LDPE is 25%.

[0040] The total thickness of the UV barrier film prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com