Preparation method for phosphorus-nitrogen doped carbon nanotube

A nitrogen-doped carbon and nanotube technology, applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve problems such as increasing the disorder of the hexagonal carbon frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

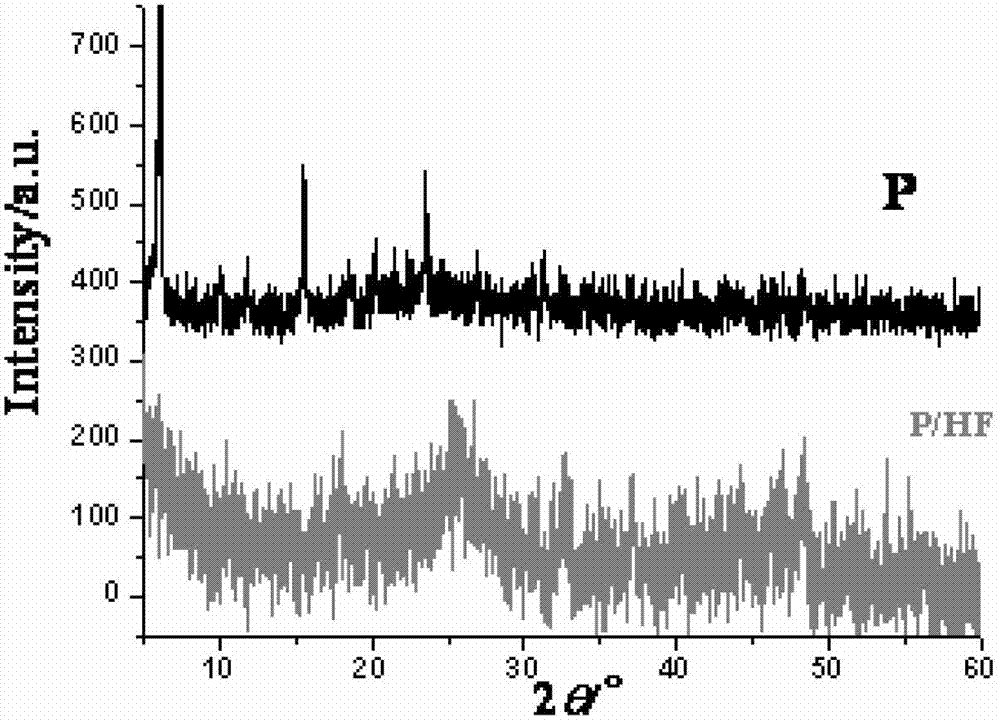

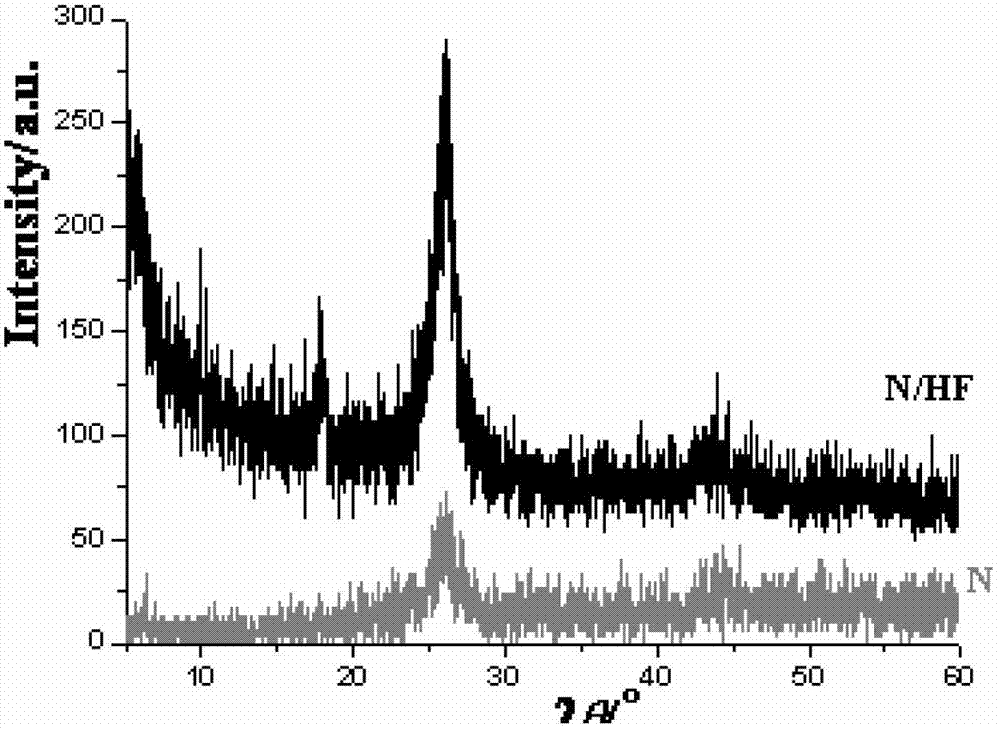

[0021] Put 1g Fe / NaY molecular sieve and 0.5g red phosphorus into the ceramic boat, heat the quartz tube furnace to 1073K, then pass the mixed gas of Ar / diethylamine at the flow rate of 20mL / min, keep the temperature for 1h, and cool naturally, that is, A mixture of black phosphorus-nitrogen doped carbon nanotubes and Fe / NaY molecular sieves was obtained by removing Fe / NaY molecular sieves in HF dilute solution to obtain phosphorus-nitrogen doped carbon nanotubes. At this time, the chemical formula of phosphorus-nitrogen doped carbon nanotubes is: CNxPy, x=0.6, y=0.55;

[0022] Results and discussion

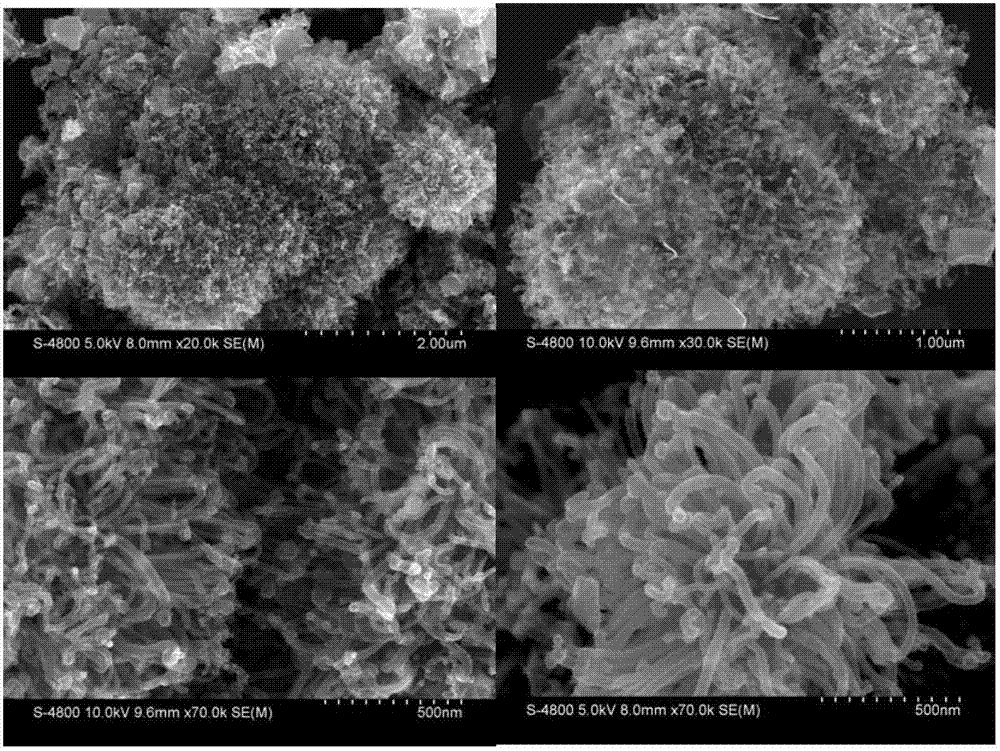

[0023] figure 1 .1 is the SEM scanning electron micrograph of the phosphorus-nitrogen doped carbon nanotubes prepared in Example 1. It can be seen from the figure that the phosphorus-nitrogen doped carbon nanotubes prepared by using iron-containing microporous Y-type molecular sieve as a catalyst, diethylamine, and red phosphorus as raw materials grow from the center, like a ...

Embodiment 2

[0035] Put 1g Fe / NaY molecular sieve and 1g red phosphorus into the ceramic boat, heat the quartz tube furnace to 1073K, then pass the mixed gas of Ar / diethylamine at a flow rate of 20mL / min, keep the temperature for 1h, and cool naturally to obtain black The mixture of phosphorus-nitrogen doped carbon nanotubes and Fe / NaY molecular sieves is obtained by removing Fe / NaY molecular sieves in HF dilute solution to obtain phosphorus-nitrogen doped carbon nanotubes. The chemical formula of phosphorus-nitrogen doped carbon nanotubes at this time is: CNxPy, x=0.6, y=0.65; it can be seen that under the same conditions, the more red phosphorus there is, the higher the phosphorus content of the obtained product is.

Embodiment 3

[0037] Put 1g Fe / NaY molecular sieve and 0.5g red phosphorus into the porcelain boat, heat the quartz tube furnace to 1073K, then pass the mixed gas of Ar / diethylamine at the flow rate of 30mL / min, keep the temperature for 1h, and cool naturally, that is, A mixture of black phosphorus-nitrogen doped carbon nanotubes and Fe / NaY molecular sieves was obtained by removing Fe / NaY molecular sieves in HF dilute solution to obtain phosphorus-nitrogen doped carbon nanotubes. The chemical formula of phosphorus-nitrogen doped carbon nanotubes at this time is: CNxPy, x=0.6, y=0.6; It can be seen that under the same conditions, the faster the flow rate of the Ar / diethylamine mixed gas is, the higher the phosphorus content of the resulting product will be. high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com