Electrolytic flotation equipment

An electrolytic air flotation and equipment technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of affecting equipment promotion, reducing current efficiency, and high treatment costs, and achieving the effect of promoting biochemical treatment, prolonging residence time, and removing COD.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

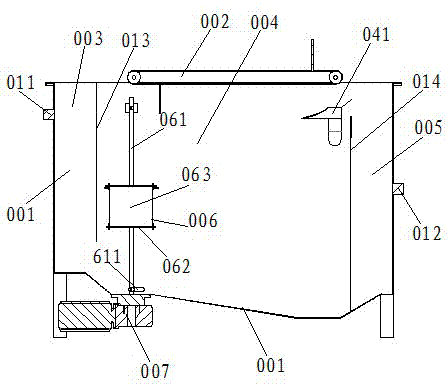

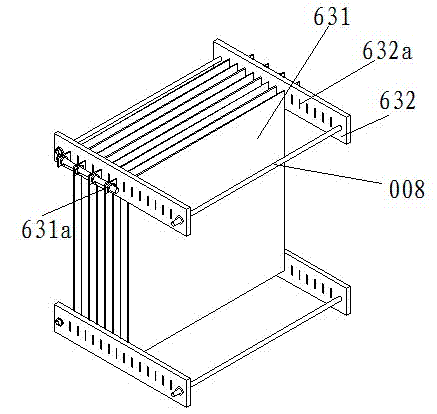

[0021] Such as figure 1 , 2 As shown, an electrolytic air flotation device includes a shell 001, the water inlet 011 and the water outlet 012 are respectively arranged on both sides of the shell 001, the slag scraping device 002 is set on the top of the shell 001, and the shell 001 is arranged at intervals in turn. The buffer baffle 013 and the overflow weir 014 divide the shell 001 into a buffer zone 003, a mixing zone 004, and a water outlet zone 005. The shell 001 above the end of the mixing zone 004 is provided with a corresponding slag scraping device 002. The slag discharge tank 041, the electrolytic generator 006 is provided at the bottom of the front end of the mixing zone 004, and the electrolytic generator 006 includes a guide rod 061, a mobile platform 062, and several electrode groups 063, and the guide rod 061 is vertical It is directly fixed on the bottom shell 001 at the front end of the mixing zone 004, the bottom end of the guide rod 061 is provided with a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com