Preparation method of long chain branched polyethylene

A polyethylene and long-branched technology, which is applied in the field of long-branched polyethylene preparation, can solve problems such as difficulty in stability, thickness limitation, and high cost, and achieve excellent foaming performance, controllable branching degree, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 carries out the preparation of long branched polyethylene in solution:

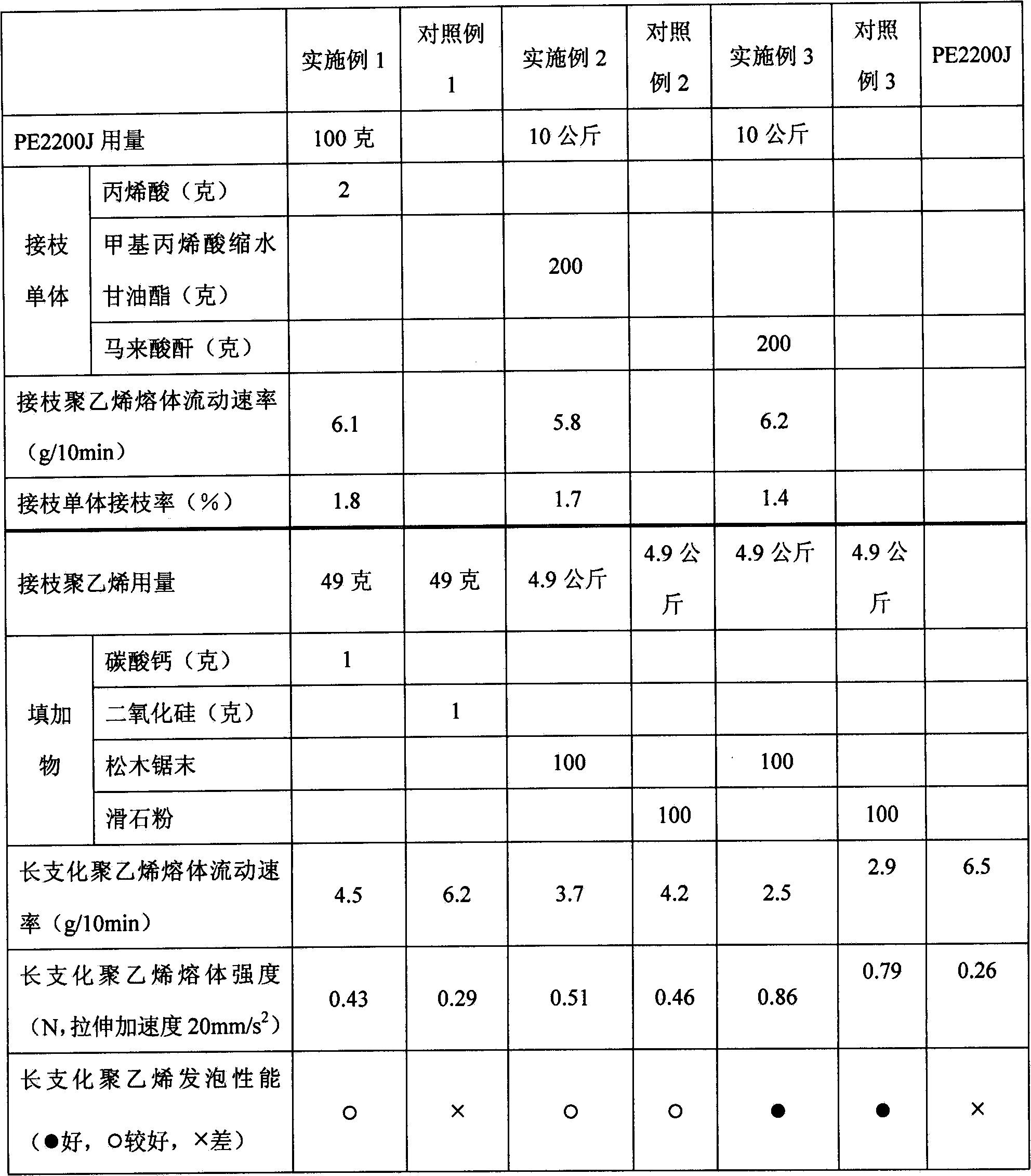

[0050] Take 100 grams of polyethylene 2200J (Daqing Petrochemical, melt index 6.0g / 10min), put it into a 2000ml flask, then add 1300 grams of xylene, and gradually raise the temperature to 130°C. After all the solids were dissolved, 2 grams of acrylic acid and 2 grams of styrene were added, and then 0.36 grams of benzoyl peroxide were added to the flask in 5 times within 30 minutes, and the reaction was maintained at 130°C. After the reaction, the flask was cooled to room temperature, 100 g of acetone was added, and after stirring, the solid was completely precipitated, and then dried in a vacuum oven to obtain grafted polyethylene. The results of the grafting ratio of acrylic acid and polyethylene are shown in Table 1.

[0051] Take 49g of grafted polyethylene prepared by the above method and 0.24g of 1010 antioxidant and add it to a 2000ml flask, then add 1000g of xylene, and gradua...

Embodiment 2

[0053] Embodiment 2 carries out the preparation of long-branched polyethylene by melting method:

[0054] Get 10 kilograms of polyethylene 2200J (Daqing Petrochemical, melt index 6.0g / 10min), 0.2 kilograms of glycidyl methacrylate graft monomer, 0.2 kilogram of styrene, 36 grams of dicumyl peroxide, diisopropyl peroxide Propylbenzene was dissolved in the monomers of glycidyl methacrylate and styrene, and then they were all put into a high-speed mixer and mixed for 2 minutes before discharging. The mixture was added to a twin-screw extruder that had been preheated to 170° C., and extruded at a speed of 50 rpm. The extruded product is pelletized to obtain grafted polyethylene. The results of the grafting ratio of glycidyl methacrylate to polyethylene are shown in Table 1.

[0055] Get 4.9 kilograms of graft polyethylene prepared by the above method, 20 grams of antioxidant, 20 grams of catalyzer, 100 grams of pine sawdust, and then all put into a high-speed mixer and mix for 2...

Embodiment 3

[0057] Embodiment 3: The grafting method is the same as that of Embodiment 2, except that maleic anhydride is used as a grafting monomer to carry out grafting reaction with polyethylene. The method that it reacts with the filler pine sawdust is also exactly the same as in Example 2. The results of the grafting ratio of maleic anhydride and polyethylene and the properties of the obtained long-branched polyethylene are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com