Method for producing methane from kitchen waste by two continuous anaerobic fermentation steps

A technology for kitchen waste and anaerobic fermentation, which is applied in biochemical equipment and methods, bioreactors for gas production, biochemical instruments, etc., can solve the problem that the two-phase anaerobic fermentation process is difficult to operate continuously, and the acidification and hydrolysis of kitchen waste produces biogas. Low efficiency and other problems, to achieve the effects of reducing operating costs, high methane production rate, and improving degradation efficiency and biogas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

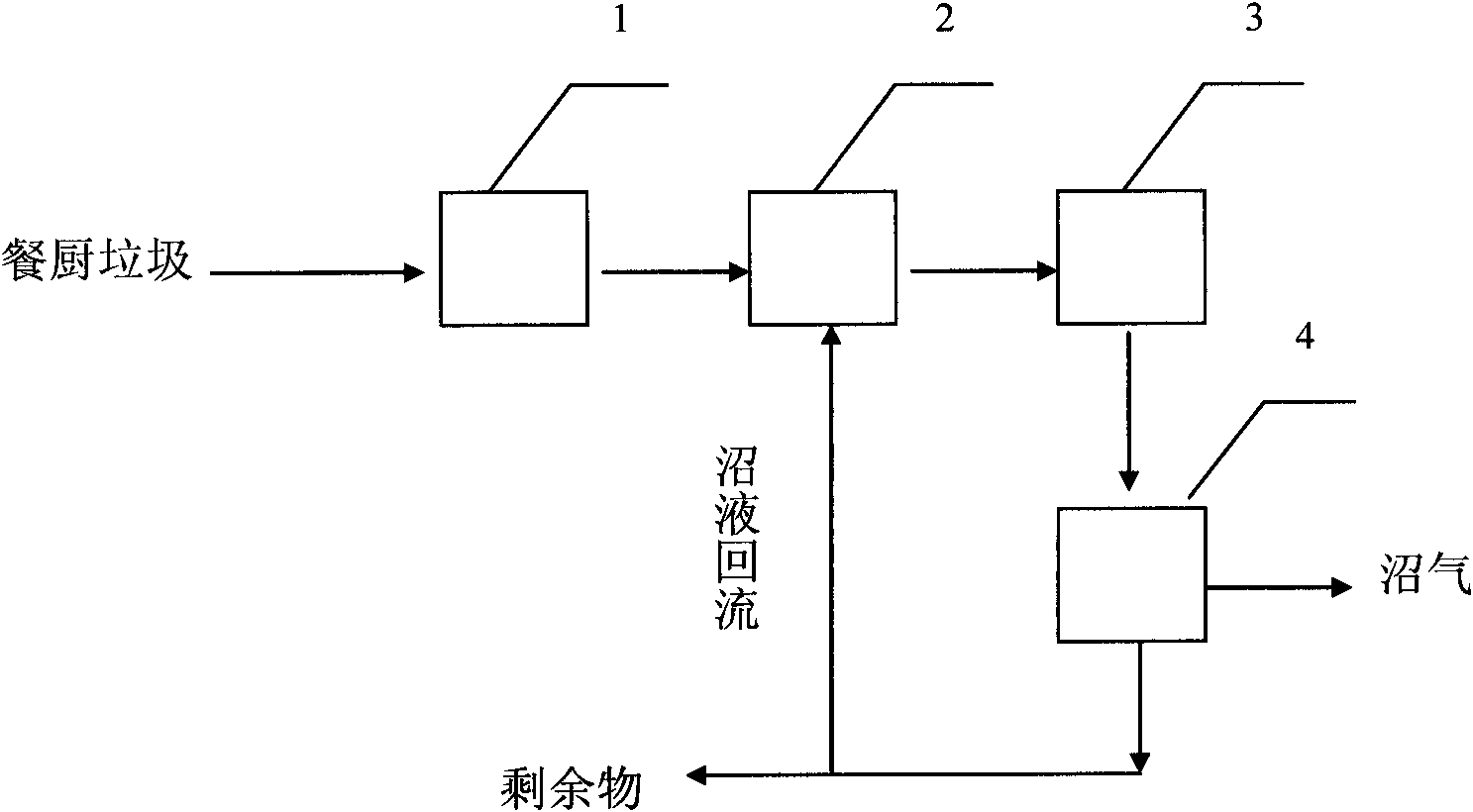

[0033] The kitchen waste was taken from Qingdao Fengfeng Ecological Food Garden, and large solid inorganic substances such as chopsticks, shells, and plastics were removed, and then crushed and beaten with a food beater 1. The composition and solid content of the kitchen waste after beating were measured as shown in Table 1 and shown in Table 2. Mix and dilute the pulped food waste and water through the dilution device 2, and the solid content of the food waste after dilution is 75gVS / L. The anaerobic digestion sludge of the inoculum was taken from Qingdao Tuandao Sewage Treatment Plant, concentrated by centrifugation, and the solid content of the concentrated inoculum was measured (see Table 2).

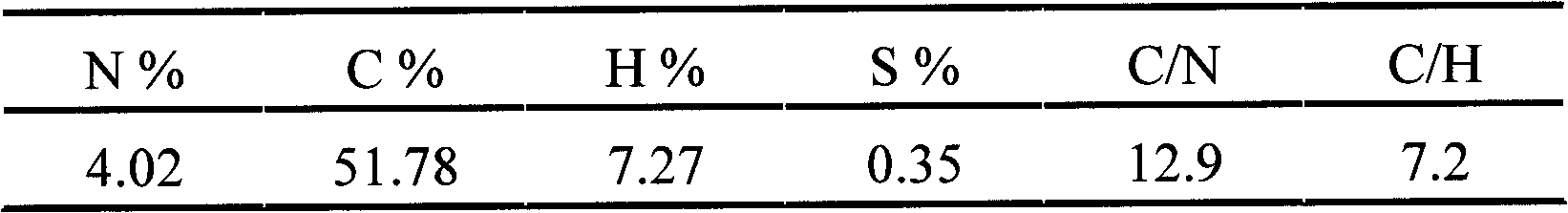

[0034] Table 1 Composition of food waste elements

[0035]

[0036] Table 2 Solid content of food waste and inoculum

[0037]

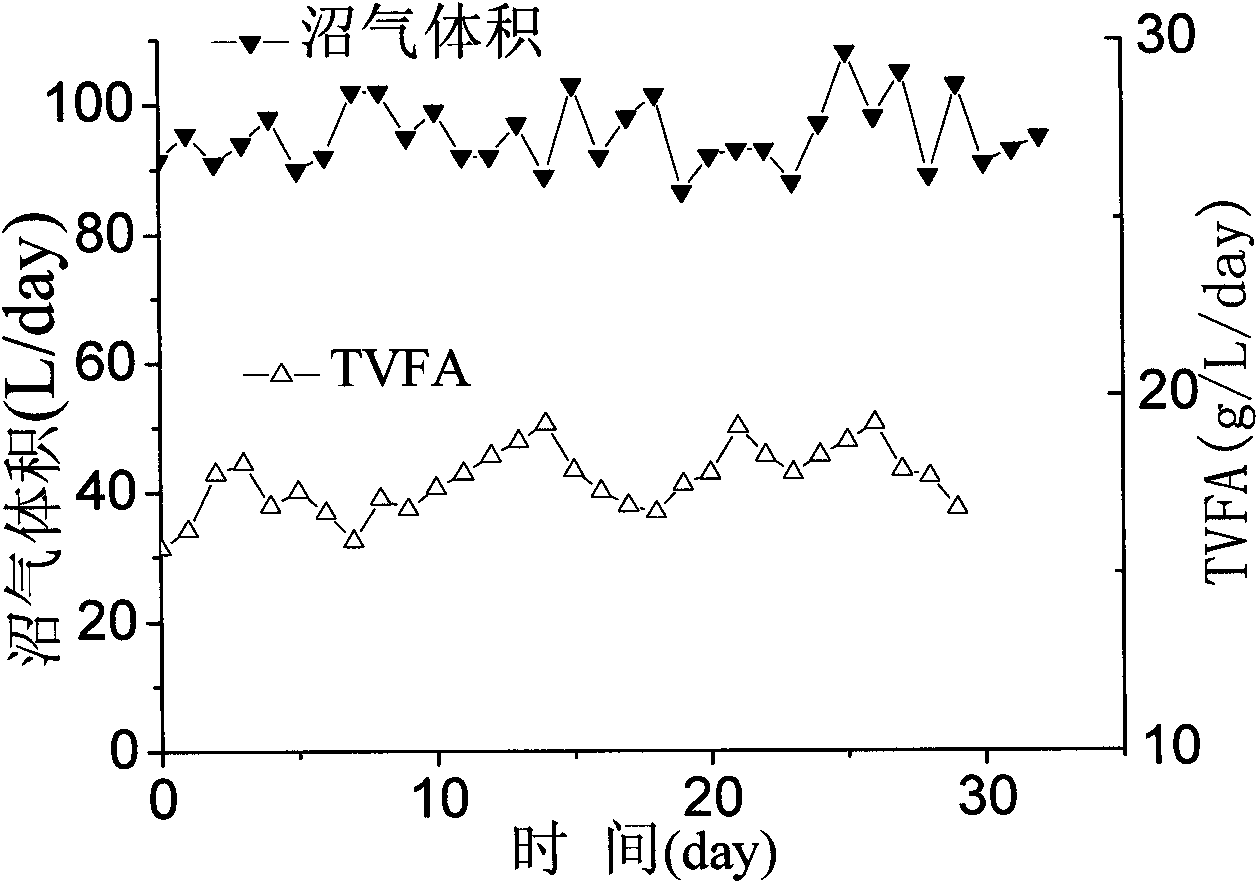

[0038] Add the diluted food waste to the first CSTR fermenter 3, the volume of the fermenter is 5L, first add 4.5L of food waste, blow with nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com